Special powdery water reducing agent for high-strength sprayed concrete

A technology of sprayed concrete and powdery water reducer, which is applied in the field of water reducer, can solve the problems of water reducer handling and storage troubles, and achieve the effect of improving concrete structure, improving workability, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: A special powdery water reducer for high-strength shotcrete, including the following components by weight, 825 parts of compressed silica fume; plasticizer: 18 parts; binder: 4 parts; surfactant: 3 parts ; Slump retaining agent: 22 parts; high-efficiency water reducer: 88 parts.

[0022] Wherein: the high-efficiency water reducer is a naphthalenesulfonate formaldehyde condensate with a solid content of 1.5%<Na2SO4 content<2.5%. The plasticizer is phthalic acid diester; the surfactant is carboxyl ester; and the slump retaining agent is wood calcium.

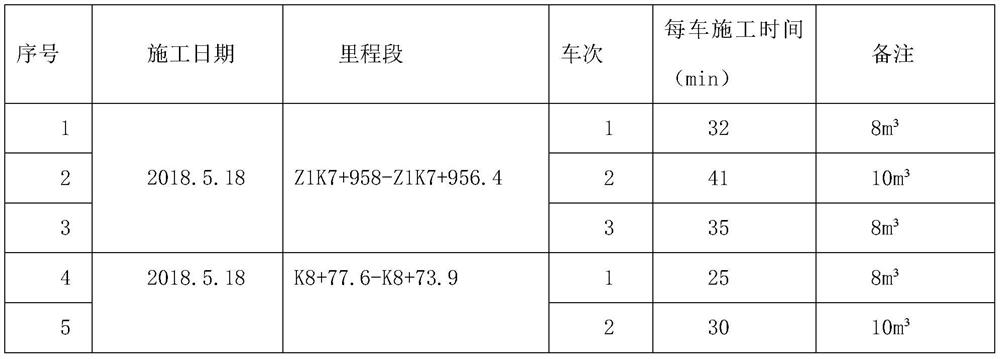

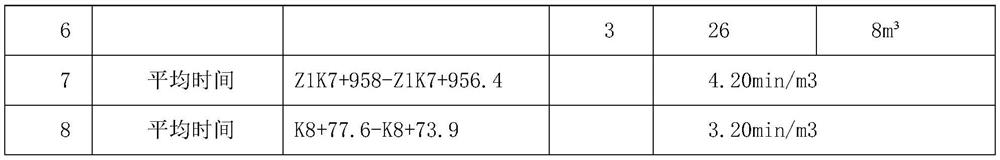

[0023] The comparison and analysis of the special powder water reducing agent mixed with high-strength shotcrete according to the present invention and ordinary admixture shotcrete is as follows:

[0024] According to the specific construction situation of a certain project department, the exit of a certain tunnel is constructed with HPS3016S concrete spraying trolley. Shotcrete has the following problems: the ...

Embodiment 2

[0048] Example 2: The special powder water reducer for high-strength shotcrete of the present invention includes the following components by weight, 850 parts of compressed silica fume; plasticizer: 35 parts; binder: 3 parts; surfactant: 8 parts parts; slump retaining agent: 50 parts; superplasticizer: 60 parts. Wherein: the plasticizer is a combination of phthalic acid diester and diethyl phthalate. The surfactant is lignosulfonate. The slump retaining agent is polycarboxylic acid.

[0049] The function of the water reducer is to improve the workability of the concrete while keeping the mix ratio unchanged; or to reduce the water consumption and improve the concrete strength while keeping the workability unchanged; or to reduce the amount of cement while keeping the strength constant , save cement and reduce costs. At the same time, the concrete is more uniform and dense after adding the water reducing agent, improving a series of physical and chemical properties, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com