Method for preparing ultra-white glass material by purifying fine-grained quartz sandstone

A technology of ultra-clear glass and quartz, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of fine-grained quartz sandstone separation and purification difficulties, achieve positive environmental benefits, expand sources, and realize reasonable The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

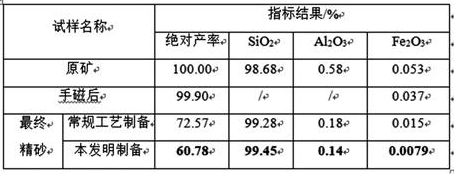

[0027] Taking fine-grained quartz sandstone minerals in a certain place in Sichuan as an example, the original ore pictures are shown in figure 2 .

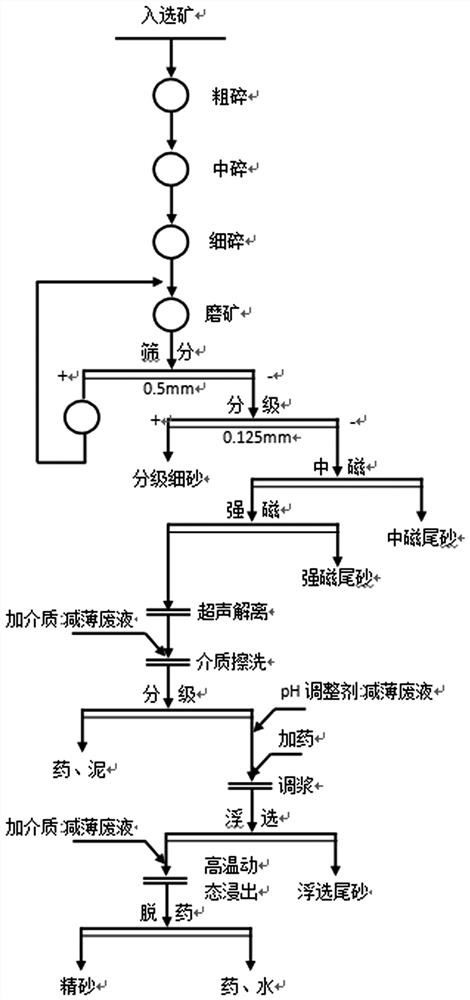

[0028] Adopting the method of the present invention, that is, a method for preparing ultra-clear glass materials by purifying fine-grained quartz sandstone, is characterized in that it comprises the following steps:

[0029] a) Crushing: crushing the quartz sandstone ore to below the target size, preparing for sorting and further processing;

[0030] b) (impeded or) screening: control the upper limit of the particle size of the crushed product, and provide a suitable grinding particle size for the grinding operation;

[0031] c) Grinding: fully dissociate the quartz sandstone minerals to meet the target particle size requirement;

[0032] d) Pre-screening or inspection: control the particle size of the quartz sandstone below the upper limit of the target particle size;

[0033] e) Classification: control the lower limit of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com