Method for treating wastewater generated in white carbon black production process by precipitation process

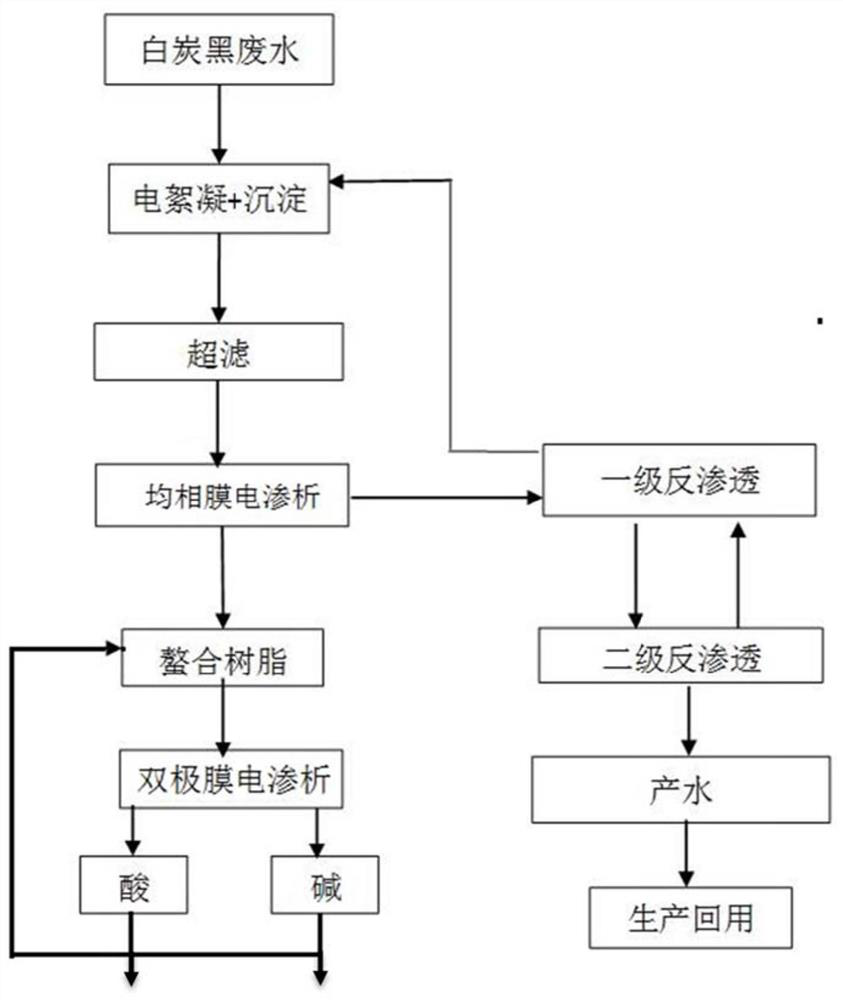

A treatment method and technology of precipitation method, which can be used in sedimentation treatment, filtration treatment, multi-stage water treatment, etc., can solve the problem of insufficient resource utilization of wastewater, and achieve the effect of small footprint, easy hardening prevention, and longevity guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] S1: The white carbon black wastewater containing sodium sulfate with a mass fraction of 1-5% is treated by plate and frame filter press and then passed into an electrocoagulation system for the first step of pretreatment. Adjust the current density of the electrocoagulation system to 80A / m 2 , power on for a certain period of time to ensure that the silica content of the wastewater in the effluent treated by the electrocoagulation system is lower than 15mg / L.

[0044] Subsequently, the produced water treated by the electrocoagulation system is passed into the radial flow sedimentation tank, and the wastewater is allowed to stay in the radial flow sedimentation tank for 2 hours. After the impurities in the wastewater are completely precipitated, most of the suspended matter in the wastewater is separated. , so as to obtain the produced water and sludge impurities. Sludge impurities enter the plate and frame filter press to recover the silicon in the sludge or directly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com