Continuous chlorination reaction device and method for producing trichloroacetaldehyde

A technology of trichloroacetaldehyde and chlorination reaction, applied in chemical instruments and methods, organic chemistry, preparation of carbon-based compounds, etc., can solve the problems of few reaction stages, low yield of trichloroethanol, difficult production process, and the like, Achieve the effect of reducing the consumption of raw materials, the requirements of the device structure and the requirements of the reaction conditions are simple, and the utilization rate is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

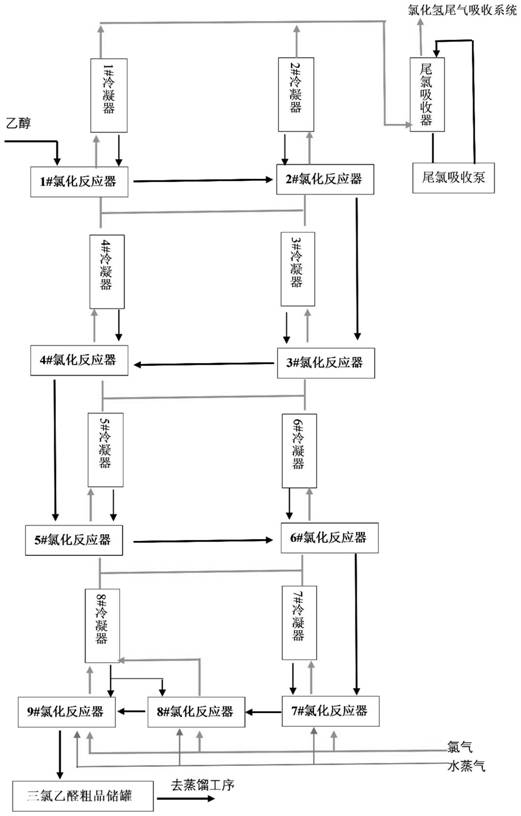

Embodiment 1

[0042] Equipment used: 1# to 9# chlorination reactors are all 2m 3 , 1# to 8# condensers are all 20m 2 , tail chlorine absorber 20m 2 , Tail chlorine absorption pump 1.6m 3 / h, Chloral crude product storage tank 5000L.

[0043] 95% ethanol (700kg / h) enters from 1# chlorination reactor, controls the reaction temperature at 40-50°C, continuously overflows from top to bottom to 2# chlorination reactor, controls the reaction temperature at 50-60°C, and overflows To 3# chlorination reactor, control the reaction temperature 60-70°C, overflow to 4# chlorination reactor, control the reaction temperature 70-80°C, overflow to 5# chlorination reactor, control the reaction temperature 80-85 ℃, overflow to 6# chlorination reactor, control the reaction temperature 85-90 ℃, overflow to 7# chlorination reactor, control the reaction temperature 90-95 ℃, overflow to 8# chlorination reactor, control the reaction The temperature is 95-100°C, overflow to 9# chlorination reactor, control the re...

Embodiment 2

[0048] Equipment used: 1# to 9# chlorination reactors are all 2m 3 , 1# to 8# condensers are all 20m 2 , tail chlorine absorber 20m 2 , Tail chlorine absorption pump 1.6m 3 / h, Chloral crude product storage tank 5000L.

[0049] 95% ethanol (700kg / h) enters from 1# chlorination reactor, controls the reaction temperature at 40-50°C, continuously overflows from top to bottom to 2# chlorination reactor, controls the reaction temperature at 50-60°C, and overflows To 3# chlorination reactor, control the reaction temperature 60-70°C, overflow to 4# chlorination reactor, control the reaction temperature 70-80°C, overflow to 5# chlorination reactor, control the reaction temperature 80-85 ℃, overflow to 6# chlorination reactor, control the reaction temperature 85-90 ℃, overflow to 7# chlorination reactor, control the reaction temperature 90-95 ℃, overflow to 8# chlorination reactor, control the reaction The temperature is 95-100°C, overflow to 9# chlorination reactor, control the re...

Embodiment 3

[0054] Equipment used: 1# to 9# chlorination reactors are all 2m 3 , 1# to 8# condensers are all 20m 2 , tail chlorine absorber 20m 2 , Tail chlorine absorption pump 1.6m 3 / h, Chloral crude product storage tank 5000L.

[0055] 95% ethanol (600kg / h) enters from the 1# anti-chlorination reactor, controls the reaction temperature at 40-50°C, continuously overflows from top to bottom to the 2# chlorination reactor, controls the reaction temperature at 50-60°C, and overflows Flow to 3# chlorination reactor, control reaction temperature 60-70°C, overflow to 4# chlorination reactor, control reaction temperature 70-80°C, overflow to 5# chlorination reactor, control reaction temperature 80- 85°C, overflow to 6# chlorination reactor, control the reaction temperature 85-90°C, overflow to 7# chlorination reactor, control the reaction temperature 90-95°C, overflow to 8# chlorination reactor, control The reaction temperature is 95-100°C, overflow to 9# chlorination reactor, control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com