Alloy electrocatalyst for ultra-stable PEM oxygen evolution reaction and preparation method thereof

A technology of electrocatalyst and oxygen evolution reaction, applied in the direction of non-precious metal oxide coating, electrode, electrode coating, etc., can solve the problems of easy corrosion, catalyst change, PEM electrolysis hydrogen production equipment overall performance attenuation, etc., to achieve ultra-high Stability, simple preparation process, suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

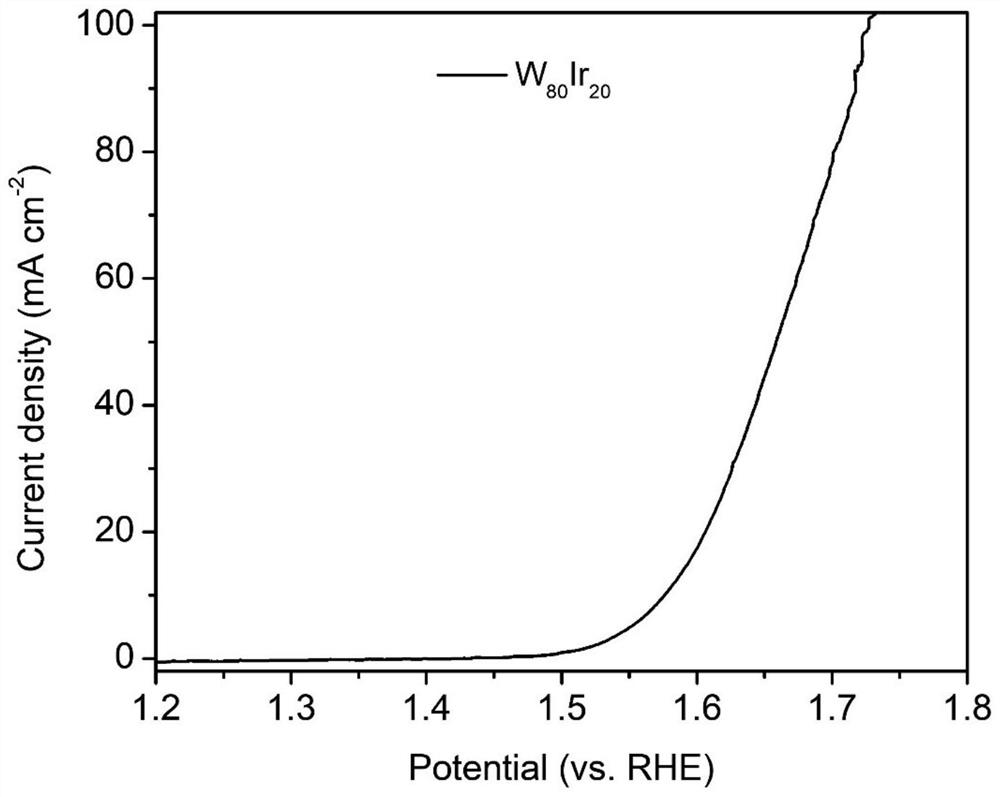

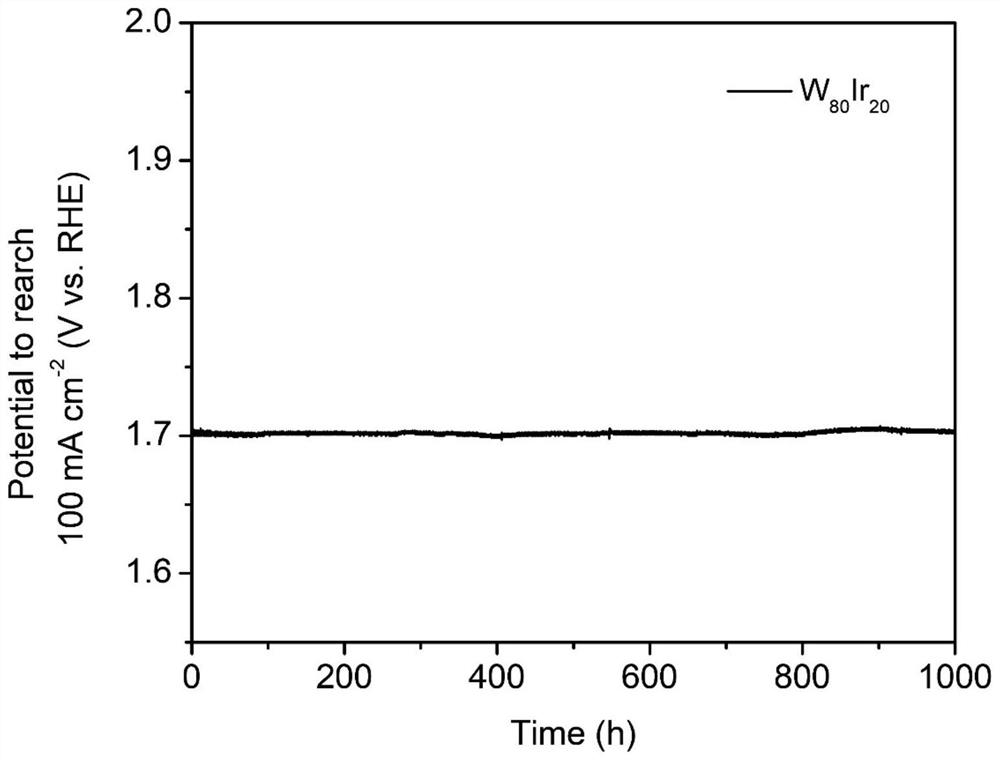

[0032] In this example, the nominal composition of the alloy we choose is W 80 Ir 20 , the preparation of the electrocatalyst material is as follows:

[0033](1) Master alloy ingot preparation: according to the nominal composition W of the master alloy 80 Ir 20 The alloy raw materials W and Ir (purity 98.0-99.9wt%) are mixed, and then under the protection of high-purity Ar atmosphere, arc melting is carried out. The melting current is 200A-300A. In order to ensure the uniform composition of the alloy, the master alloy is repeatedly turned over in the furnace Melting more than four times to obtain a master alloy ingot.

[0034] (2) Alloy casting molding: The uniform master alloy ingot in step (1) is melted again by electric arc melting, and then the molten alloy is infiltrated into the water-cooled copper mold by negative pressure suction casting, and the alloy melt is in the copper mold. Medium cooling to obtain a W with a diameter of 2mm 80 Ir 20 Electrocatalyst rods. ...

Embodiment 2

[0038] In this example, the nominal composition of the alloy we choose is W 60 Ir 40 , the preparation method of the electrocatalyst material is the same as in Example 1.

[0039] The alloy of gained is carried out acidic oxygen evolution reaction performance test, and test adopts three-electrode device, and test scheme is identical with embodiment 1, W 60 Ir 40 Alloy electrode material reaches 10mA / cm 2 The overpotential required for the catalytic current density is as low as about 300mV. Prepared W 60 Ir 40 The alloy electrocatalyst electrode can operate stably in 0.5mol / L sulfuric acid electrolyte for more than 1000h, and still maintain high electrocatalytic activity, and the overpotential rise rate within 1000 hours is less than 4μV / h. prove W 60 Ir 40 The alloy electrode material has electrocatalytic oxygen evolution activity.

Embodiment 3

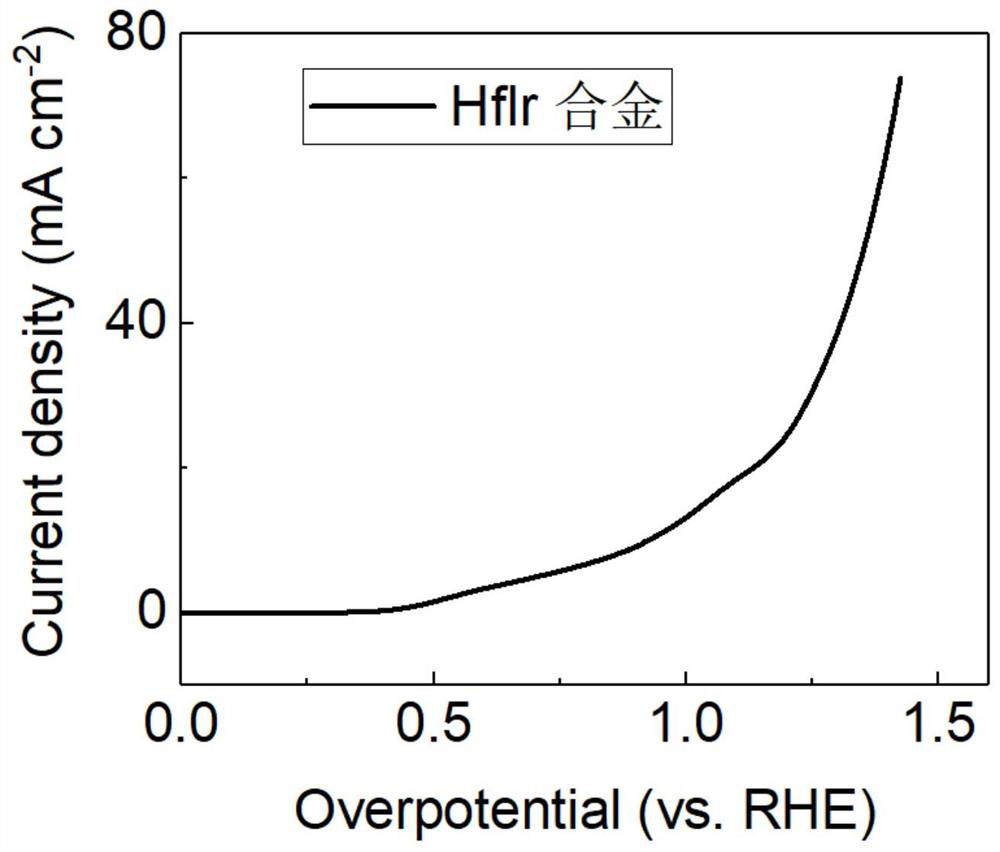

[0041] In this example, the nominal composition of the alloy we choose is Mo 80 Ir 20 , the preparation method of the electrocatalyst material is the same as in Example 1.

[0042] The obtained alloy is subjected to acidic oxygen evolution reaction performance test, and the test adopts a three-electrode device, and the test scheme is the same as in Example 1, Mo 80 Ir 20 Alloy electrode material reaches 10mA / cm 2 The overpotential required for the catalytic current density is as low as 643mV. Prepared Mo 80 Ir 20 The alloy electrocatalyst electrode can operate stably in 0.5mol / L sulfuric acid electrolyte for more than 1000h, and still maintain high electrocatalytic activity, and the overpotential rise rate within 1000 hours is less than 7μV / h. prove Mo 80 Ir 20 The alloy electrode material has electrocatalytic oxygen evolution activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com