Variable-frequency heat source tower heat pump water chiller-heater unit

A heat source tower heat pump, cold and hot water unit technology, applied in the direction of heating and cooling combination, heat pump, refrigerator, etc., can solve the problems of not meeting the needs of high energy efficiency and saving energy, and low heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

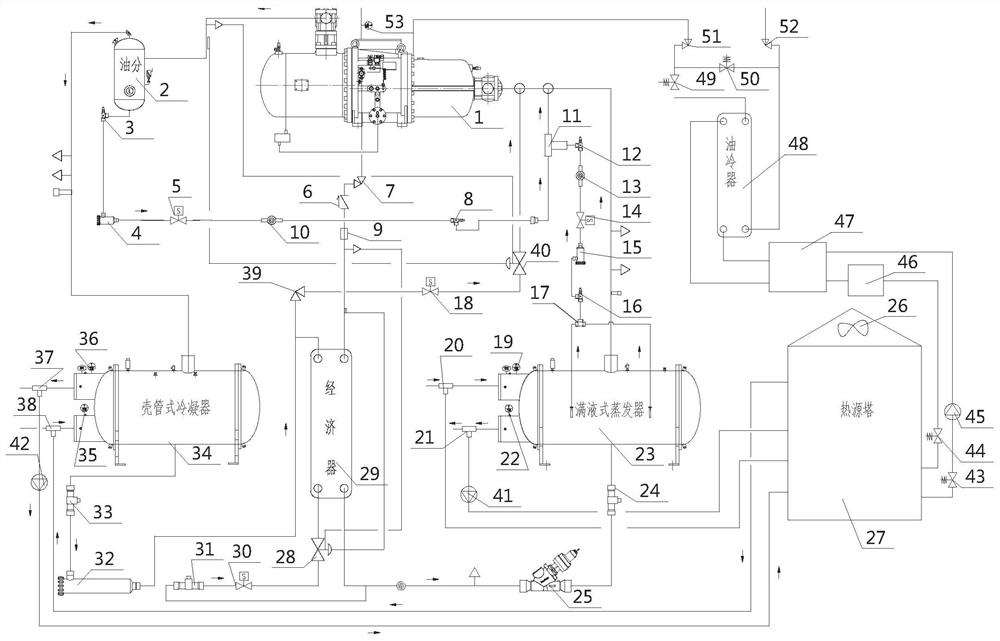

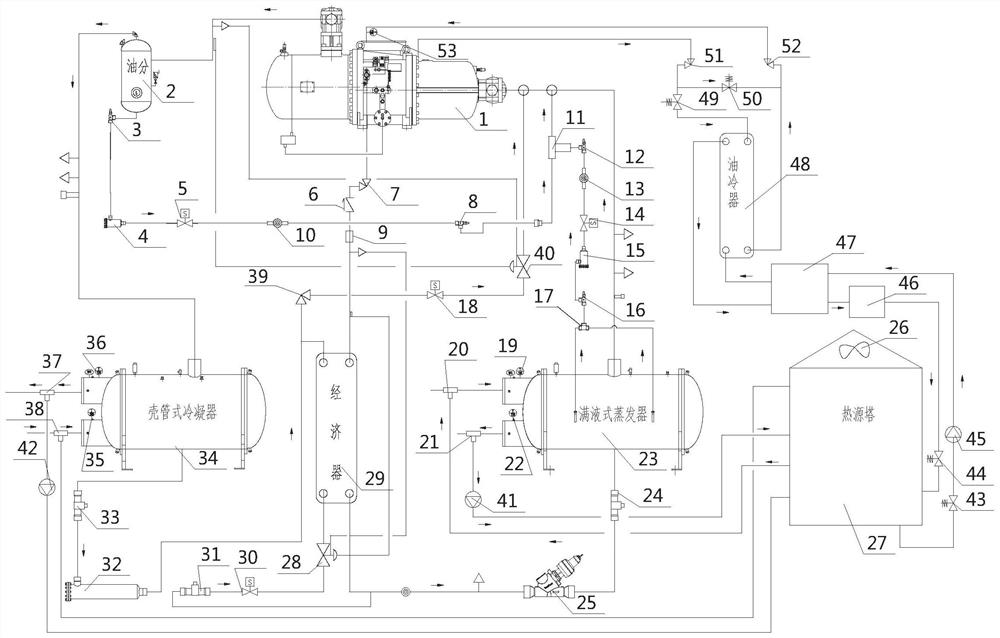

[0070] The technical solution of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0071] The frequency conversion type heat source tower heat pump cold and hot water unit of the present invention, the schematic diagram of cooling is as follows figure 1 As shown, the principle diagram of heating is as follows figure 2 shown. The unit includes compressor 1, condenser 34, evaporator 23, first expansion valve 25, heat source tower 27, economizer 29, oil separator 2, frequency conversion fan 26, first electric three-way valve 37, second electric three-way valve Through valve 38, third electric three-way valve 21, fourth electric three-way valve 20, first stop valve 3, first oil filter 4, first solenoid valve 5, first sight glass 10, second stop valve 8. Ejection pump 11, third stop valve 12, second sight glass 13, second solenoid valve 14, second oil filter 15, fourth stop valve 16, first three-way 17, fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com