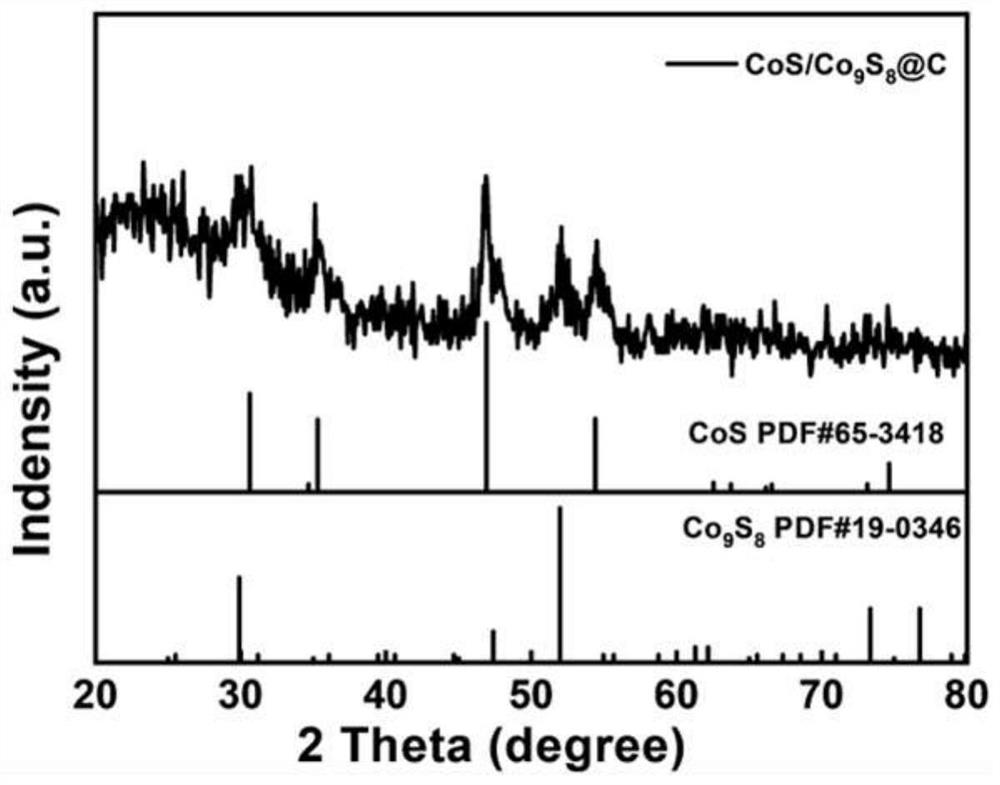

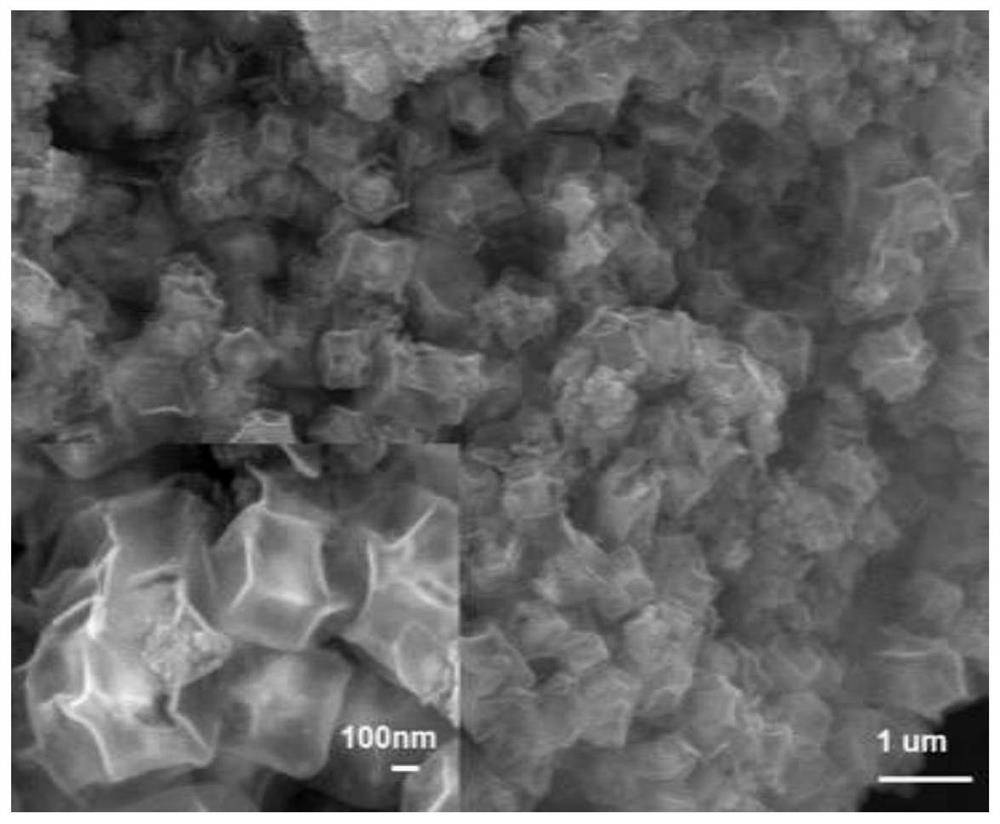

Preparation method of CoS/Co9S8@C core-shell structure nano composite sodium ion battery negative electrode material

A sodium-ion battery, nanocomposite technology, applied in battery electrodes, negative electrodes, nanotechnology and other directions, can solve the problems of loss of electrochemical activity, poor conductivity of cobalt sulfide, volume expansion, etc., to inhibit the collapse of material structure and enhance conductivity. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Co-N / C precursor synthesis process:

[0026] First, respectively dissolve cobalt nitrate hexahydrate and 2-methylimidazole in 20ml of methanol solution to obtain purple solution A and transparent colorless solution B. Mix and stir the two solutions of A and B for 30 minutes, let them stand overnight, and depressurize The purple solid was obtained by suction filtration, which was dried in a blast oven at 60°C for 12 hours, and the dried ZIF-67 was heated at 5°C·min under an argon atmosphere. -1 The heating rate was maintained at 500 °C for 1 h to obtain a Co-N / C precursor.

[0027] 2) Hydrothermal process: Add the Co-N / C precursor and thioacetamide at a mass ratio of 1:2 to 30ml of water and stir to dissolve, then transfer the mixed solution to a reactor for 3 hours at 180°C, and centrifuge , and dried in a blast oven at 60°C for 12 hours to obtain cobalt sulfide.

[0028] 3) Carbon coating process: Dissolve cobalt sulfide in 200ml Tris-HCl buffer solution with pH =...

Embodiment 2

[0033] 1) Co-N / C precursor synthesis process:

[0034] First, respectively dissolve cobalt nitrate hexahydrate and 2-methylimidazole in 20ml of methanol solution to obtain purple solution A and transparent colorless solution B. Mix and stir the two solutions of A and B for 30 minutes, let them stand overnight, and depressurize The purple solid was obtained by suction filtration, which was dried in a blast oven at 60°C for 12 hours, and the dried ZIF-67 was heated at 5°C·min under an argon atmosphere. -1 The heating rate was maintained at 500 °C for 1 h to obtain a Co-N / C precursor.

[0035]2) Hydrothermal process: Add the Co-N / C precursor and thioacetamide at a mass ratio of 1:2 to 30ml of water and stir to dissolve, then transfer the mixed solution to a reactor for 3 hours at 180°C, and centrifuge , and dried in a blast oven at 60°C for 12 hours to obtain cobalt sulfide.

[0036] 3) Carbon coating process: Dissolve cobalt sulfide in 200ml Tris-HCl buffer solution with pH = ...

Embodiment 3

[0040] 1) Co-N / C precursor synthesis process:

[0041] First, respectively dissolve cobalt nitrate hexahydrate and 2-methylimidazole in 20ml of methanol solution to obtain purple solution A and transparent colorless solution B. Mix and stir the two solutions of A and B for 30 minutes, let them stand overnight, and depressurize The purple solid was obtained by suction filtration, which was dried in a blast oven at 60°C for 12 hours, and the dried ZIF-67 was heated at 5°C·min under an argon atmosphere. -1 The heating rate was maintained at 500 °C for 1 h to obtain a Co-N / C precursor.

[0042] 2) Hydrothermal process: Add the Co-N / C precursor and thioacetamide at a mass ratio of 1:2 to 30ml of water and stir to dissolve, then transfer the mixed solution to a reactor for 3 hours at 180°C, and centrifuge , and dried in a blast oven at 60°C for 12 hours to obtain cobalt sulfide.

[0043] 3) Carbon coating process: Dissolve cobalt sulfide in 200ml Tris-HCl buffer solution with pH =...

PUM

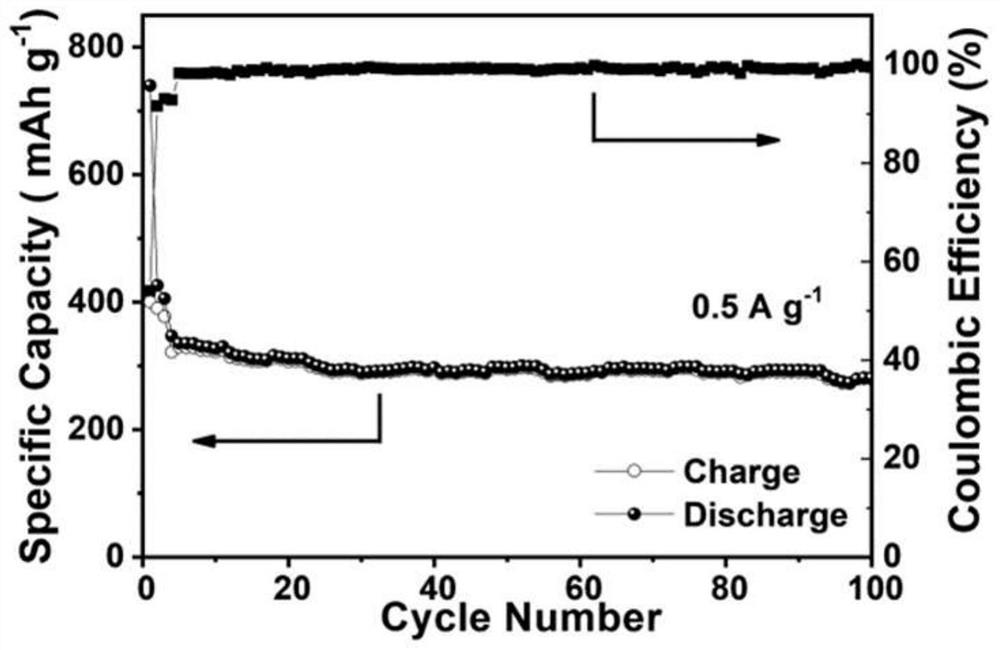

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com