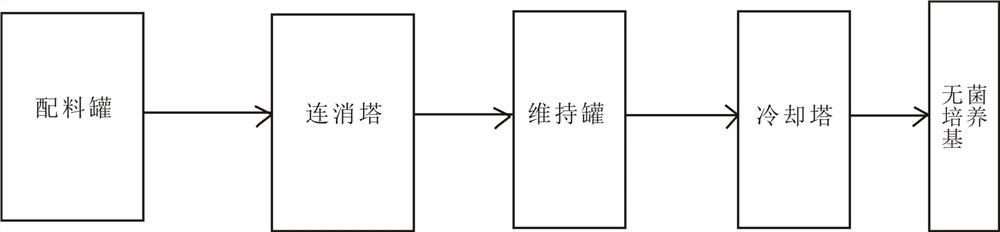

Continuous sterilization method for neomycin fermentation medium

A technology of fermentation medium and sterilization method, which is applied in the field of continuous sterilization of neomycin fermentation medium, can solve the problems of small damage to medium components and incomplete sterilization, and achieve the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

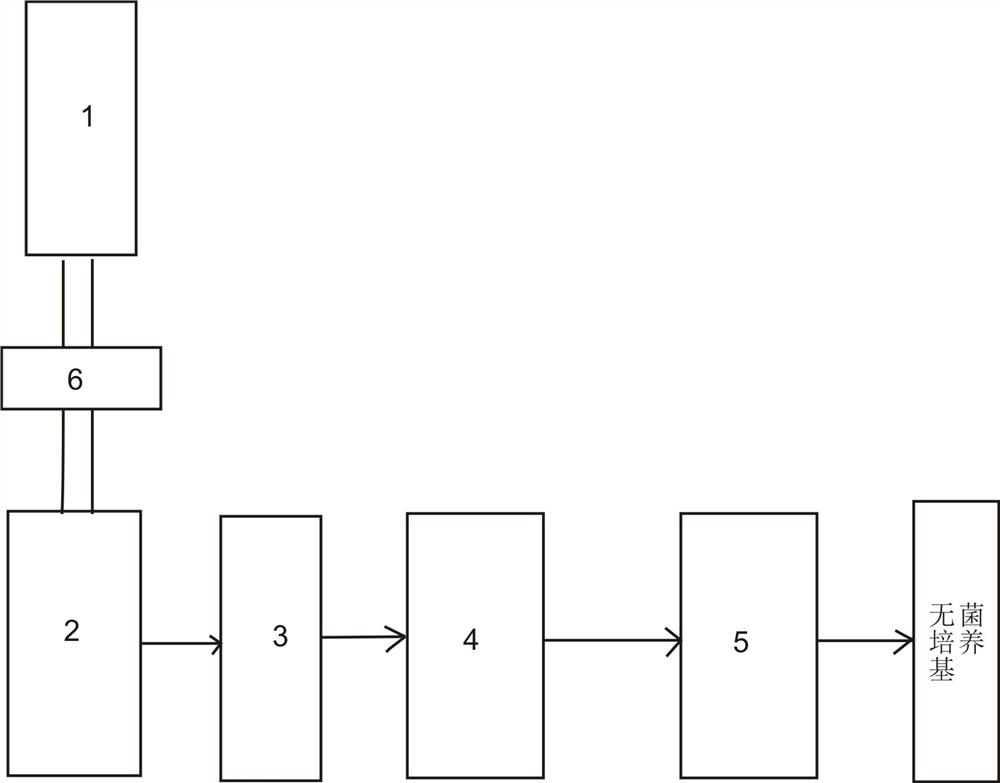

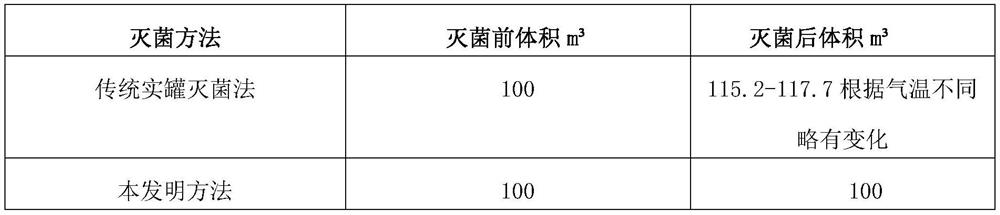

[0025] A continuous sterilization method of neomycin fermentation medium, the method may further comprise the steps:

[0026] Step 1: steam injector 6 is set on the feed pipeline of preheating tank 2, in the input process that the neomycin fermentation medium in batching tank 1 is input in preheating tank 2, utilize steam injector 6 to material Carry out the first heating, and stop heating when the temperature of the material rises to 80°C;

[0027] Step 2: Add α-amylase to the preheating tank 2, the amount of α-amylase added is 0.01% of the quality of the neomycin fermentation medium in the preheating tank 2, and maintain a temperature of 80° C. in the preheating tank 2 for 30 minutes or more;

[0028] Step 3: Input the neomycin fermentation medium into the continuous elimination tower 3, and after the second high-temperature steam injection sterilization, instantly heat the neomycin fermentation medium in the continuous elimination tower 3 to 130°C;

[0029] Step 4: input ...

Embodiment 2

[0032] A continuous sterilization method of neomycin fermentation medium, the method may further comprise the steps:

[0033] Step 1: steam injector 6 is set on the feed pipeline of preheating tank 2, in the input process that the neomycin fermentation medium in batching tank 1 is input in preheating tank 2, utilize steam injector 6 to material Carry out the first heating, and stop heating when the temperature of the material rises to 90°C;

[0034] Step 2: Add α-amylase to the preheating tank 2, the amount of α-amylase added is 0.05% of the quality of the neomycin fermentation medium in the preheating tank 2, and maintain a temperature of 90°C in the preheating tank 2 for 30 minutes or more;

[0035] Step 3: Input the neomycin fermentation medium into the continuous elimination tower 3, and after the second high-temperature steam injection sterilization, instantly heat the neomycin fermentation medium in the continuous elimination tower 3 to 140°C;

[0036] Step 4: input th...

Embodiment 3

[0039] A continuous sterilization method of neomycin fermentation medium, the method may further comprise the steps:

[0040] Step 1: steam injector 6 is set on the feed pipeline of preheating tank 2, in the input process that the neomycin fermentation medium in batching tank 1 is input in preheating tank 2, utilize steam injector 6 to material Carry out the first heating, and stop heating when the temperature of the material rises to 100°C;

[0041] Step 2: Add α-amylase to the preheating tank 2, the amount of α-amylase added is 0.1% of the quality of the neomycin fermentation medium in the preheating tank 2, and maintain a temperature of 100° C. in the preheating tank 2 for 30 minutes or more;

[0042] Step 3: Input the neomycin fermentation medium into the continuous elimination tower 3, and after the second high-temperature steam injection sterilization, instantly heat the neomycin fermentation medium in the continuous elimination tower 3 to 150°C;

[0043] Step 4: input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com