Method for starting one-stage SBR-anammox denitrification system

A denitrification, first-start technology, applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc., can solve problems such as long start-up time, prevent sludge loss, increase biomass, The effect of improving sludge settling performance

Inactive Publication Date: 2021-04-13

TIANJIN CHENGJIAN UNIV

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, one of the main bottlenecks in the application of one-stage partial nitrosation anammox technology is the long start-up time, and the start-up of the reactor is the premise and basis of the whole experimental process, and its essence is to balance the two types of functional bacteria in the reactor. That is, ammonia oxidizing bacteria (AOB, aerobic ammonia-oxidizing bacteria) and anaerobic ammonia oxidizing bacteria (AnAOB, anaerbic ammonia-oxidizing bacteria) and inhibit the growth of nitrite oxidizing bacteria (NOB, nitrite-oxidizing bacteria), AOB, AnAOB and There is a complex competitive relationship among NOBs. How to coordinate the relationship between AOB and AnAOB in a short period of time is a challenge for the one-stage short-range nitrification anammox technology.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

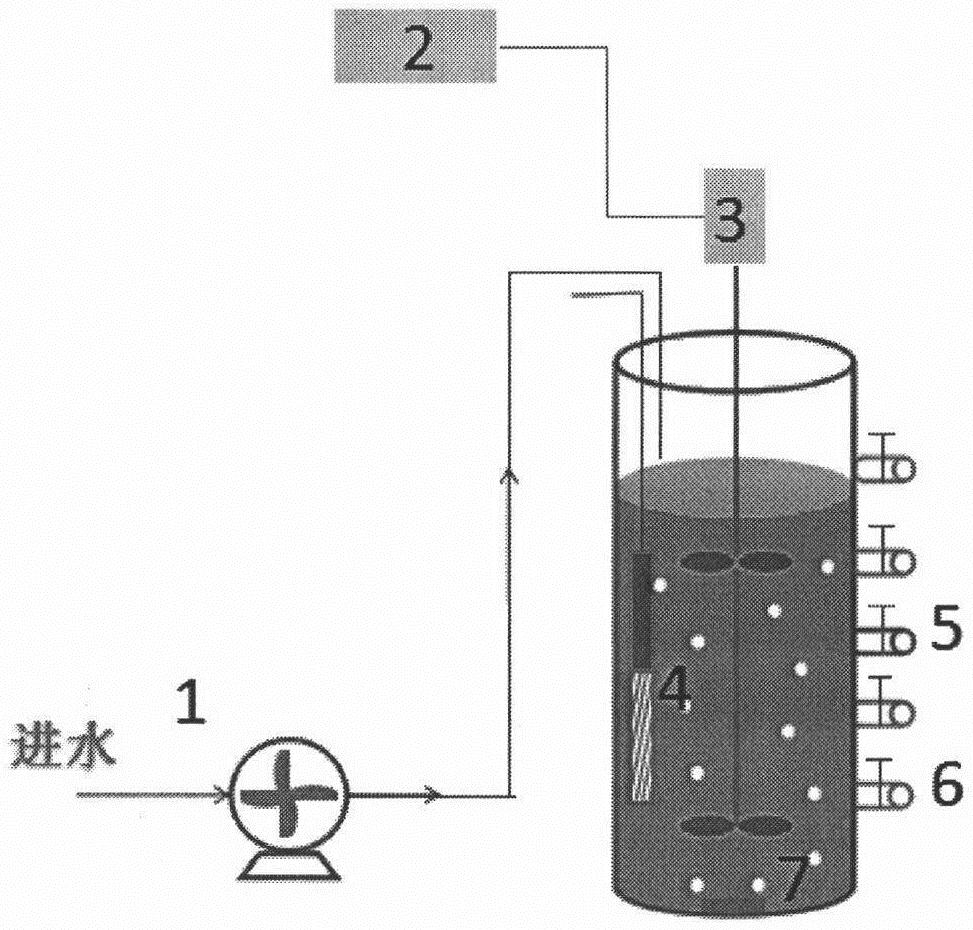

[0022] A one-stage SBR-anammox denitrification system startup method, the steps are as follows:

[0023] (1) Inoculation sludge

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

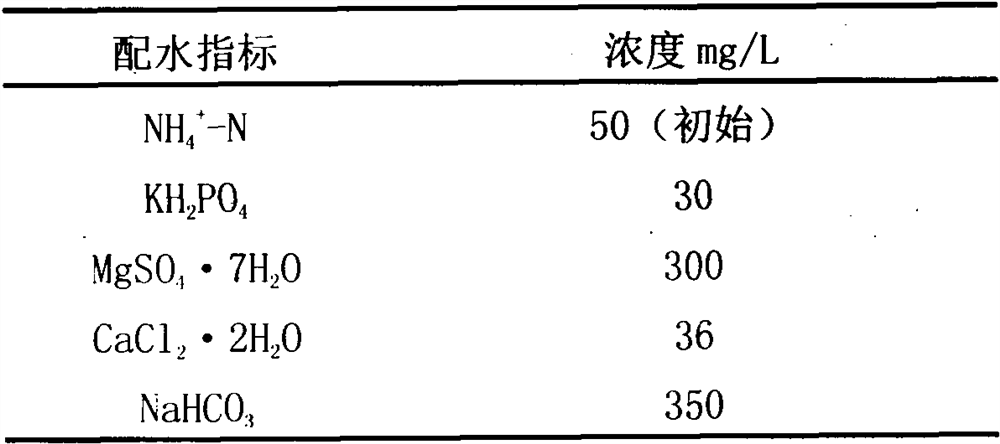

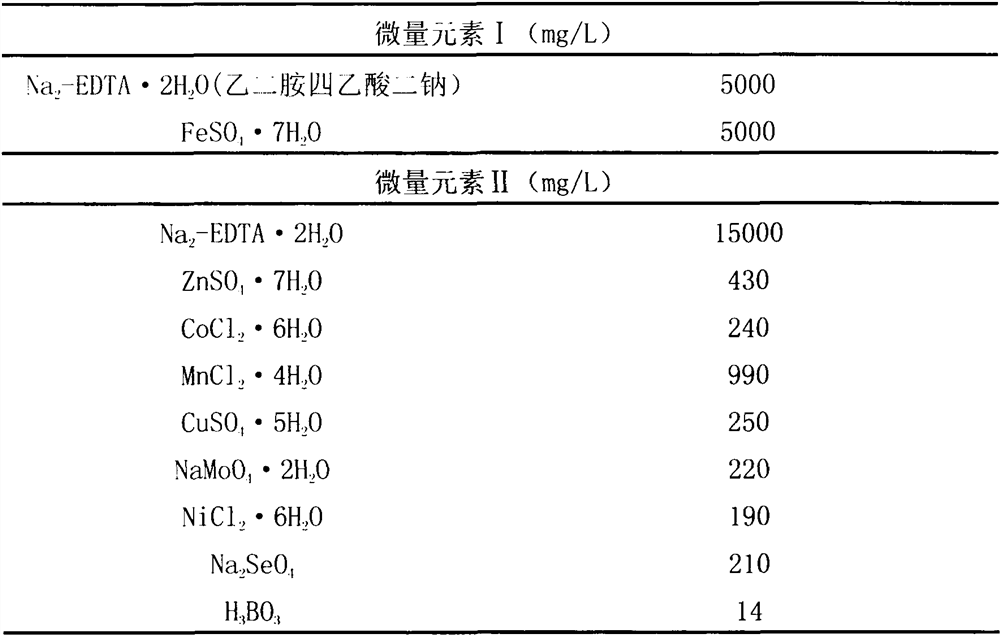

The invention discloses a method for starting a one-stage SBR-anammox system. According to the method, a one-stage partial nitrosation anaerobic ammonia oxidation system is started in a manner of starting short-cut nitrosation and then starting anaerobic ammonia oxidation. By controlling the ammonia nitrogen concentration of inlet water, HRT and DO are respectively used for starting short-cut nitrification and anaerobic ammonia oxidation for 75d and 58d. The method comprises the following steps: (1) adding a certain proportion of filler into a reactor in a short-cut nitrification stage; (2) taking return sludge of a secondary sedimentation tank as inoculation sludge, taking simulated sewage as test water, strictly controlling DO (dissolved oxygen), temperature, pH (potential of hydrogen) and inflow matrix concentration, and directly starting short-cut nitrification after aeration succeeds; and (3) inoculating a small amount of anaerobic ammonia oxidation sludge into the reactor to quickly start anaerobic ammonia oxidation so as to start one-stage partial nitrosation anaerobic ammonia oxidation. The method has the effects that partial nitrosation anaerobic ammonia oxidation system is started by adding the filler, changing the impact load and balancing the dominant bacteria of the system under the operating conditions, so that full-autotrophic biological denitrification is realized, and the operating cost is reduced.

Description

Technical field: [0001] The invention belongs to the technical field of water treatment, and in particular relates to a one-stage SBR-anammox denitrification system start-up method, which is suitable for the treatment of ammonia nitrogen-containing sewage. Background technique: [0002] In recent years, the one-stage partial nitrosation anammox technology has become a research hotspot in the field of wastewater nitrogen and phosphorus removal due to its advantages of simple process and low treatment cost. The principle is to use AOB (aerobic ammonia-oxidizing bacteria, ammonia oxidizing bacteria) to oxidize part of the ammonia nitrogen in the sewage into NO in the partial nitrification stage. 2 - -N, as the anammox electron acceptor, and then in the anammox stage, the remaining ammonia nitrogen in the sewage is used as the electron donor and the generated NO 2 - -N generates nitrogen gas under the action of AnAOB (anaerbic ammonia-oxidizing bacteria, anaerobic ammonium ox...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F3/30

CPCC02F3/307C02F2203/004C02F2203/006C02F2209/02C02F2209/06C02F2209/22C02F2209/14C02F2209/44

Inventor 王少坡何丽金于静洁王栋王晨晨刘楠楠李亚静邱春生

Owner TIANJIN CHENGJIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com