Perforated sound-absorbing ceramic prepared by taking low-grade non-metal associated ore as main raw material and preparation method thereof

A main raw material, non-metal technology, applied in the field of sound-absorbing materials, can solve the problems of high price, poor safety, high added value, and achieve the effects of excellent sound-absorbing performance, good stability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing perforated sound-absorbing ceramics prepared from low-grade non-metallic associated ore as the main raw material, comprising the following steps:

[0029] 1) Weigh tuff, magmatic soil, glass powder, silicon carbide and carbon powder respectively according to the set mass, mix them evenly, spray into sodium bicarbonate solution with a mass fraction of 5% to activate, mix and granulate;

[0030] 2) Pour the wet pellets obtained in step 1) into a 16×16cm square mold, hold the pressure for 10 minutes under a pressure of 15-20Mpa, and form a green body;

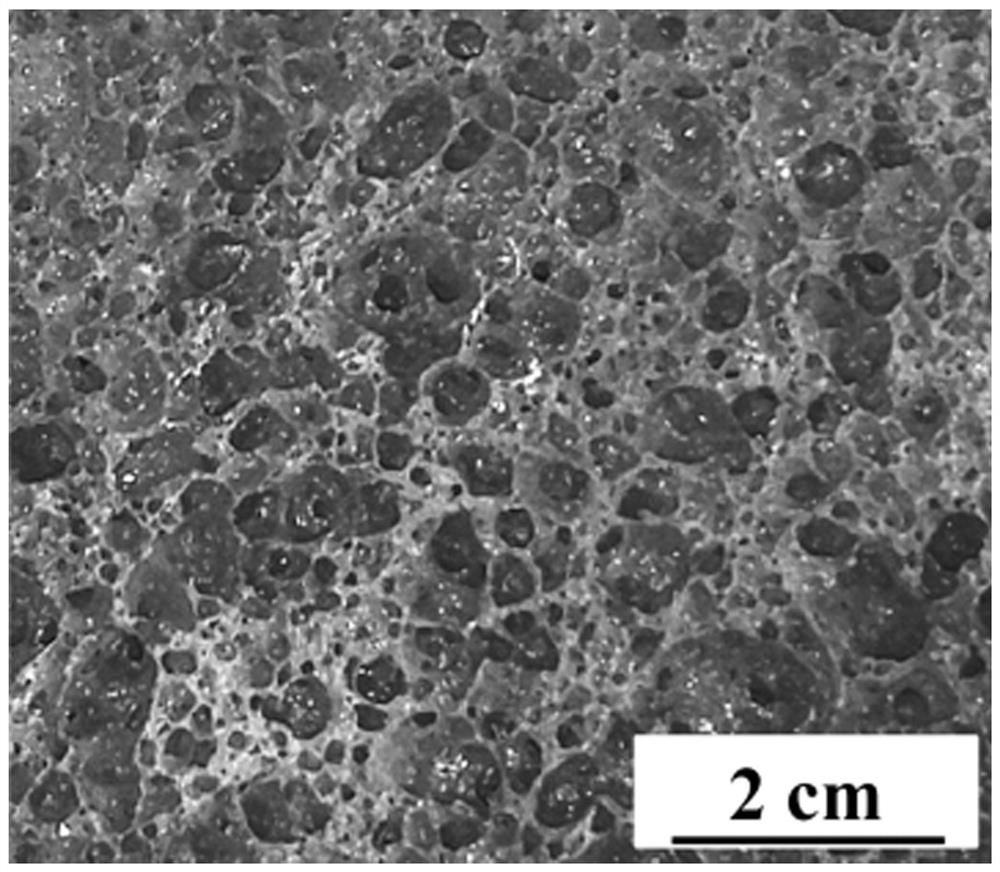

[0031] 3) Dry the green body obtained in step 2) in a drying oven at 105°C for 12-18 hours, then move it into the furnace cavity of the microwave material science workstation, and make ceramic samples according to the set sintering and heat preservation system; the samples are analyzed by modern The test technology test obtains the apparent porosity and the average sound absorption coefficient of the ...

Embodiment 1

[0036] A perforated sound-absorbing ceramic prepared with low-grade non-metallic associated minerals as the main raw material: take 1900g of tuff, 700g of magmatic soil, 208g of glass powder, 30g of silicon carbide and 48g of carbon powder and mix them evenly, and then inject 5% carbonic acid Sodium hydrogen solution is activated, mixed, and granulated; the pellets are kept at a pressure of 15Mpa for 10 minutes to obtain a green body; the green body is dried in a drying oven at 105°C for 14 hours, and then moved into the furnace cavity of the microwave material science workstation, and set for sintering The temperature is 1190°C, and the holding time is 2 hours; the ceramic samples obtained by sintering are cut into disks of specific sizes, and then their related properties are tested by modern analysis and testing techniques.

[0037] The properties of perforated sound-absorbing ceramics prepared with low-grade non-metallic associated ore as the main raw material are as follow...

Embodiment 2

[0039] A perforated sound-absorbing ceramic prepared with low-grade non-metallic associated minerals as the main raw material: take 2100g of tuff, 700g of magmatic soil, 224g of glass powder, 42g of silicon carbide and 70g of carbon powder and mix them evenly, then inject 5% carbonic acid Sodium hydrogen solution is activated, mixed and granulated; the pellets are kept at a pressure of 18Mpa for 10 minutes to obtain a green body; the green body is dried in a drying oven at 105°C for 18 hours, and then moved into the furnace cavity of the microwave material science workstation, and set for sintering The temperature is 1190°C, and the holding time is 1h; the sintered ceramic samples are cut into disks of specific sizes, and then tested for their related properties by modern analysis and testing techniques.

[0040] The properties of perforated sound-absorbing ceramics prepared with low-grade non-metallic associated ore as the main raw material are as follows: the apparent porosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com