Dy<3+> doped Na5Y(MoO4)4 warm white fluorescent powder and preparation method thereof

A fluorescent powder and warm white light technology, applied in chemical instruments and methods, luminescent materials, climate sustainability, etc., can solve problems such as agglomeration or insufficiently uniform composition, uneven distribution, and long sintering time to reduce air pollutants generation, avoiding the influence of luminous performance, and improving the effect of luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh each raw material as shown in Table 1 and put it into a 100ml beaker, add deionized water and stir at room temperature on a magnetic stirrer until the solution is clear and ready for use; weigh 2.8019g of citric acid and add it to the prepared appeal solution, Put it on a magnetic stirrer, heat and stir at 80°C for 1h, and after the water in the solution disappears, a light yellow sol-like precursor will be obtained; place the precursor in a muffle furnace, heat up to 650°C and calcinate for 1h to obtain Na 5 Y 1-x (MoO 4 ) 4 :xDy 3+ Phosphor.

[0041] Table 1

[0042]

Embodiment 2

[0044] On the basis of Example 1, change (NH 4 ) 6 Mo 7 o 24 4H 2O, (NH 4 ) 10 (H 2 W 12 o 42 )·xH 2 The amount of O used to get Na 5 Y(MoO 4 ) 4-y (WO 4 ) y :0.04Dy 3+ Phosphor. (NH 4 ) 6 Mo 7 o 24 4H 2 O and (NH 4 ) 10 (H 2 W 12 o 42 )·xH 2 The change of the corresponding amount of O is shown in Table 2.

[0045] Table 2

[0046] Na 5 Y(MoO 4 ) 4-y (WO 4 ) y :0.04Dy 3+

y=0.04 y=0.08 y=0.12 y=0.16 y=0.20 (NH 4 ) 6 Mo 7 o 24 4H 2 O(g)

2.0974 2.0763 2.0551 2.0339 2.0127 (NH 4 ) 10 (H 2 W 12 o 42 )·xH 2 O(g)

0.0306 0.0612 0.0918 0.1224 0.153

[0047] analyze:

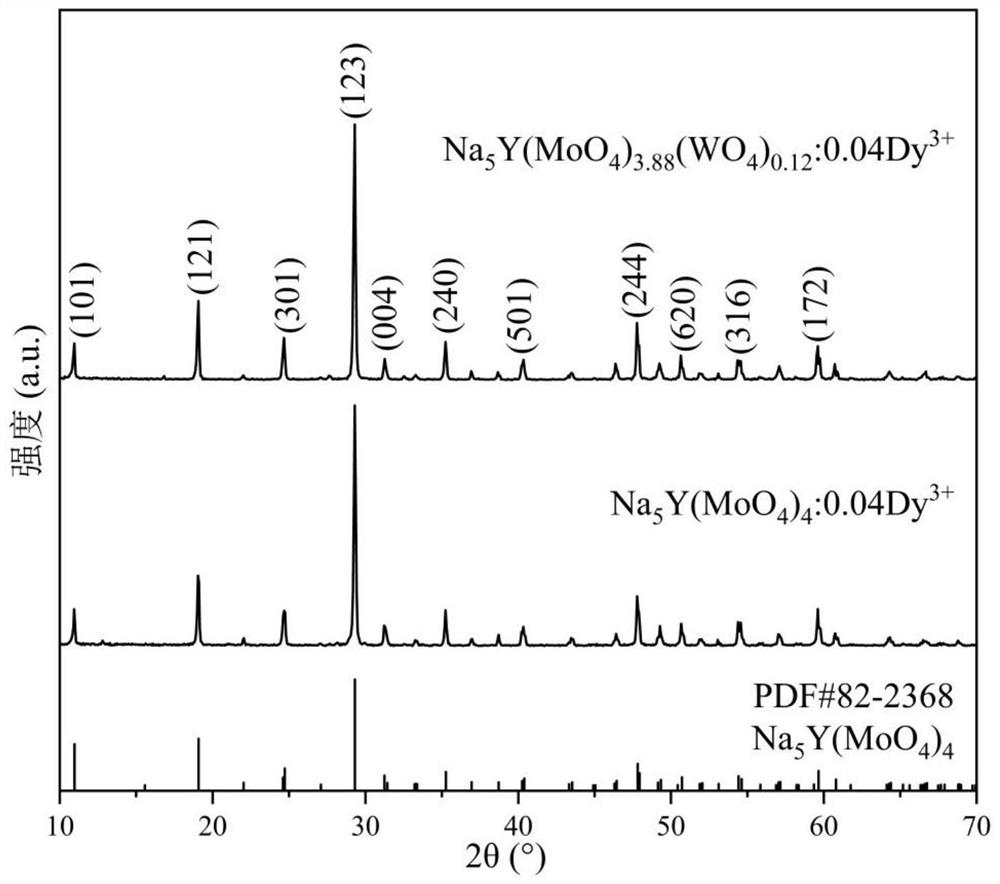

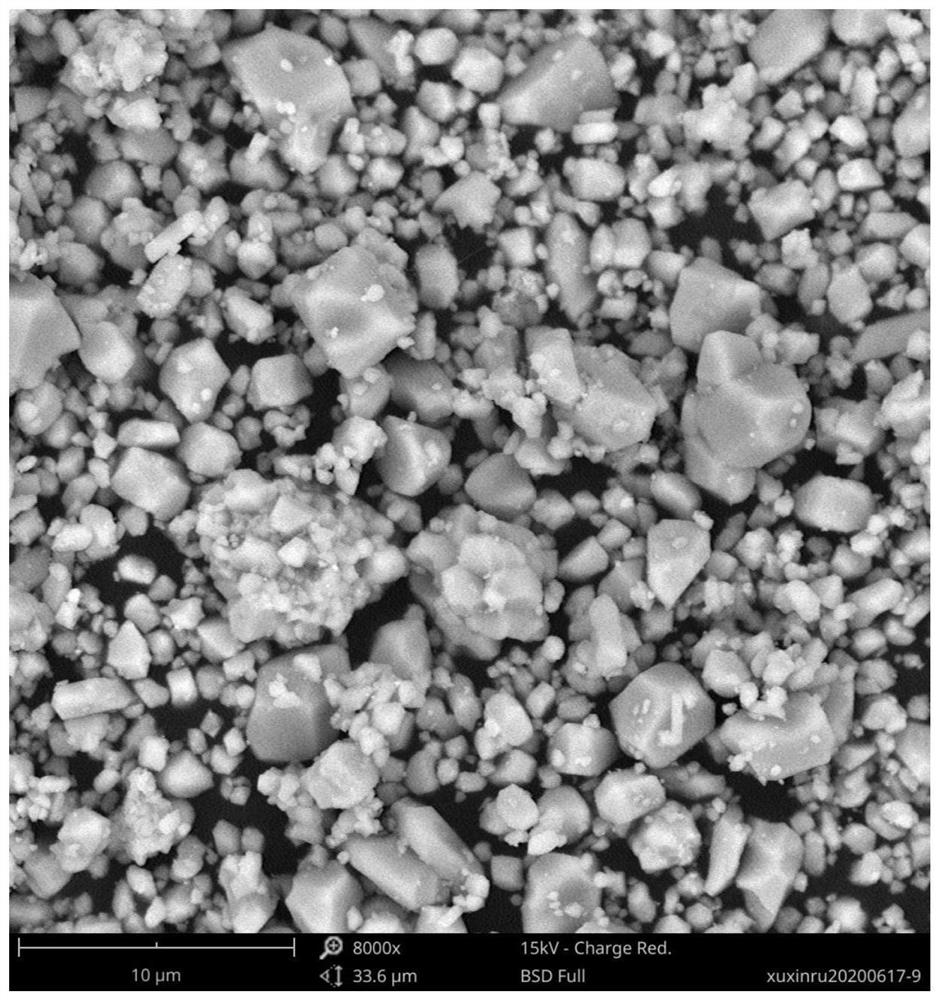

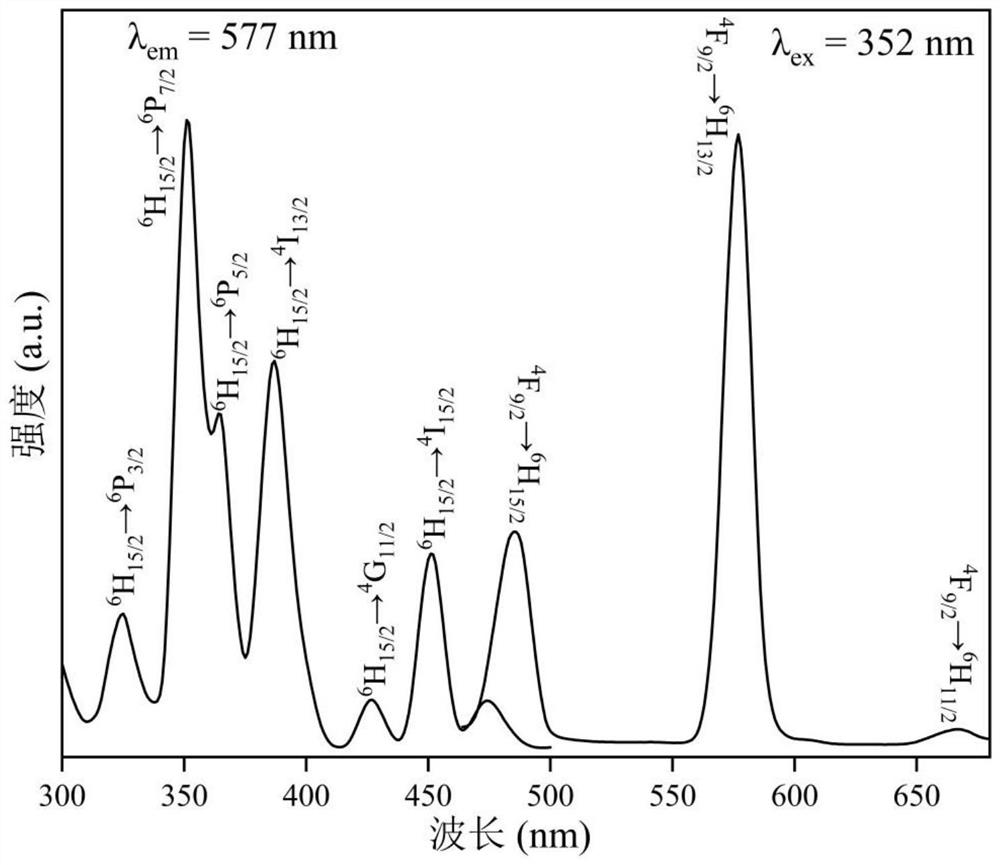

[0048] 1. Test Na 5 Y 1-x (MoO 4 ) 4-y (WO 4 ) y :xDy 3+ XRD diagram and SEM diagram, such as figure 1 and figure 2 shown. Depend on figure 1 Available: Na 5 Y 1-x (MoO 4 ) 4-y (WO 4 ) y :xDy 3+ The XRD results of the standard Na 5 Y(MoO 4 ) 4 The diffraction peaks were consistent, the sample w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com