Ash removal agent for deplating of zinc-nickel alloy electroplated layer and using method

A technology of zinc-nickel alloy and ash removal agent, applied in the field of ash removal agent, can solve the problems of fast volatilization, difficult control and large consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0050] Step (1): add 70% solvent in the tank; add 15% of agent A and 15% of agent B, and stir evenly to obtain ash remover; the specific components of agent A and agent B are shown in Table 1; A agent is made up of following components: the sodium carbonate of 70g / L and the sodium hydroxide of 130g / L; B agent is made up of following components: the sodium chlorate of 25g / L and the sodium dichromate of 40g / L; The solvent is water.

[0051] Step (2): Control the temperature of the deashing agent to 25°C;

[0052] Step (3): Soak the workpiece in the tank for 40 seconds.

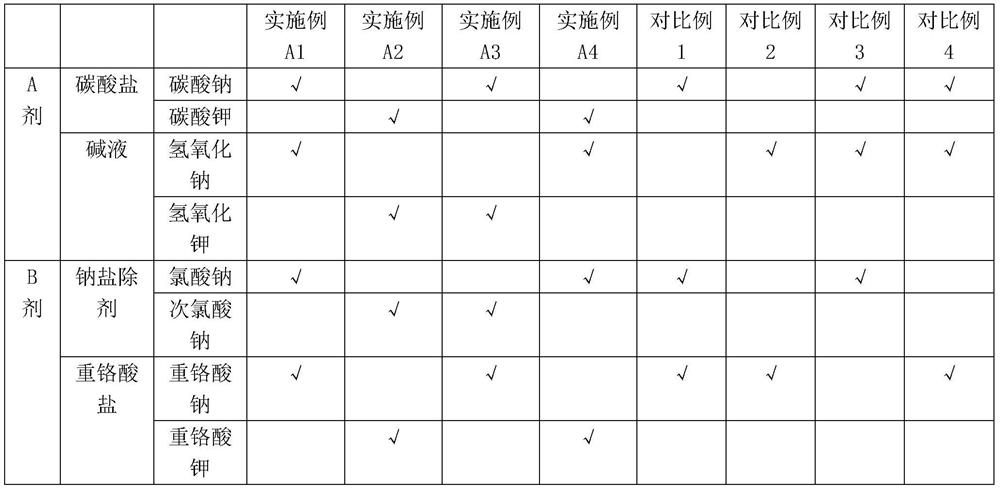

[0053] Table 1 - Component distribution of deashing agent

[0054]

[0055] The performance test of table 2-embodiment A

[0056] Example A1 Example A2 Example A3 Example A4 Comparative example A1 Comparative example A2 Comparative example A3 Comparative example A4 Exterior Level 1 Level 1 Level 1 Level 1 Level 1 Level 1 Level 1 level 2 pure water Level ...

Embodiment B

[0063] Step (1): in tank, add 65% solvent; Add 10% A agent and 25% B agent, stir and make deashing agent; A agent is made up of following components: the sodium carbonate of 60g / L and The sodium hydroxide of 140g / L; B agent is made up of following components: the sodium chlorate of 20g / L and the sodium dichromate of 45g / L, solvent is water.

[0064] Step (2): Control the temperature of the deashing agent to 60°C;

[0065] Step (3): Soak the workpiece in the tank for 30 seconds.

Embodiment C

[0067] Step (1): add 75% solvent in tank; Add 5% A agent and 20% B agent, stir and make deashing agent; A agent is made up of following components: the sodium carbonate of 80g / L and The sodium hydroxide of 120g / L; B agent is made up of following components: the sodium chlorate of 30g / L and the sodium dichromate of 30g / L, solvent is water.

[0068] Step (2): Control the temperature of the deashing agent to 50°C;

[0069] Step (3): Soak the workpiece in the tank for 60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com