Real-time optimal control method for deep neural network of injection molding machine

A deep neural network and optimal control technology, applied in the field of injection molding control, can solve problems such as time-consuming and labor-intensive, inability to achieve online real-time feedback optimal control of injection molding machines, poor robustness, etc., to reduce surface defects and residual stress , Improving the real-time performance of optimal control and the effect of strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

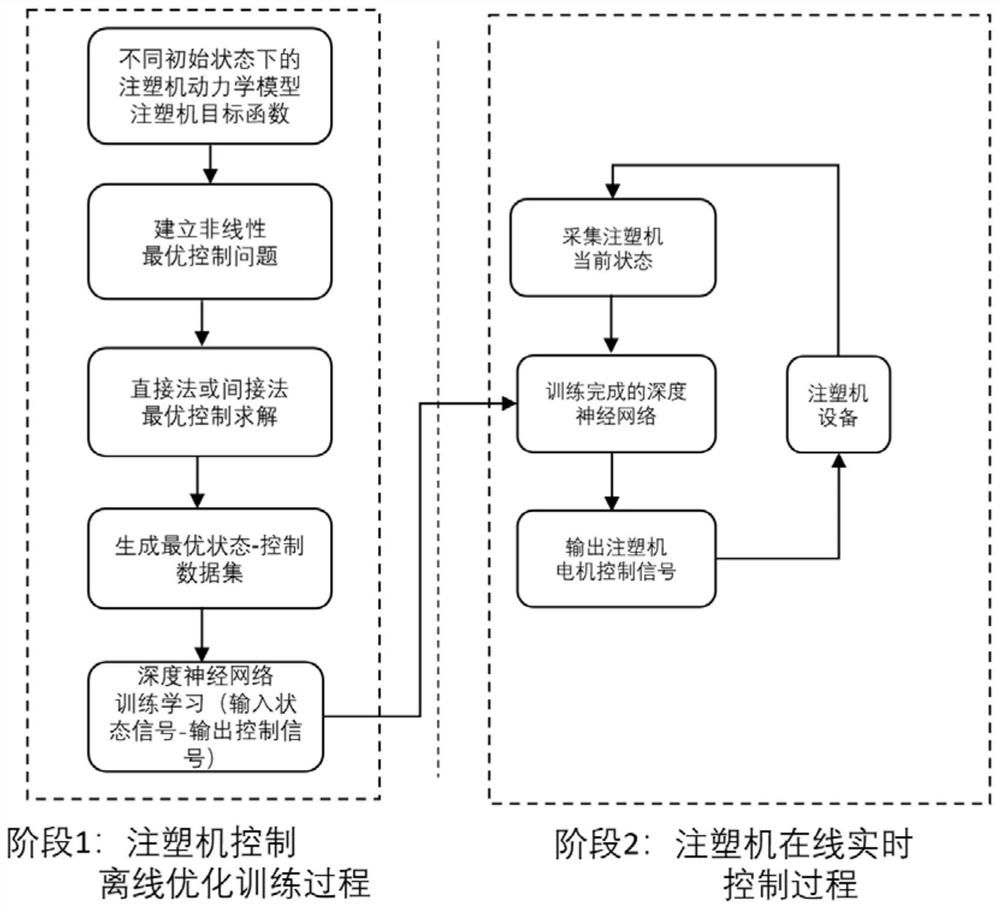

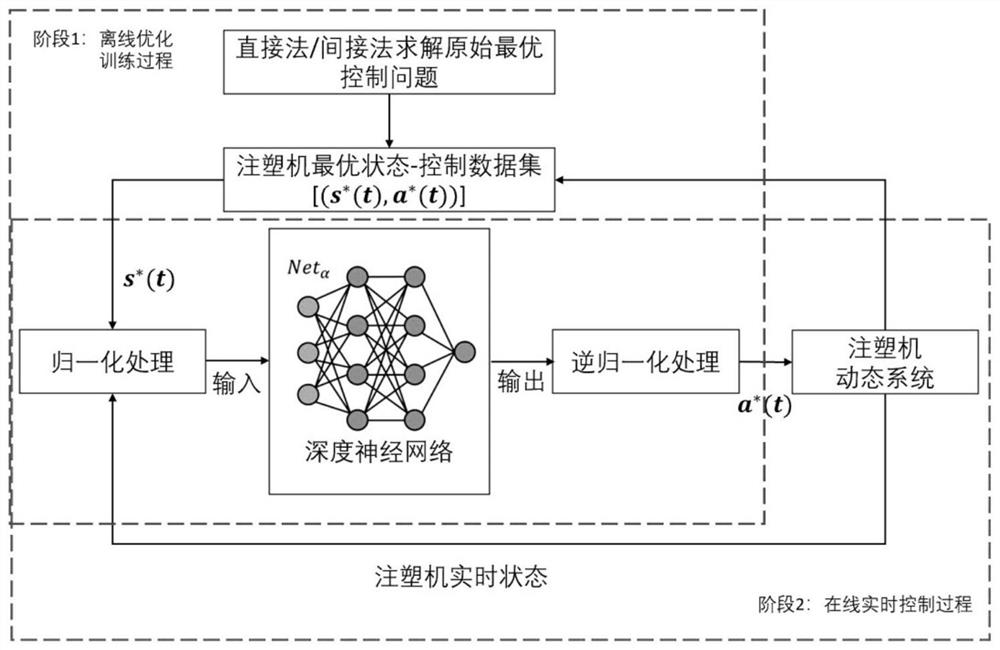

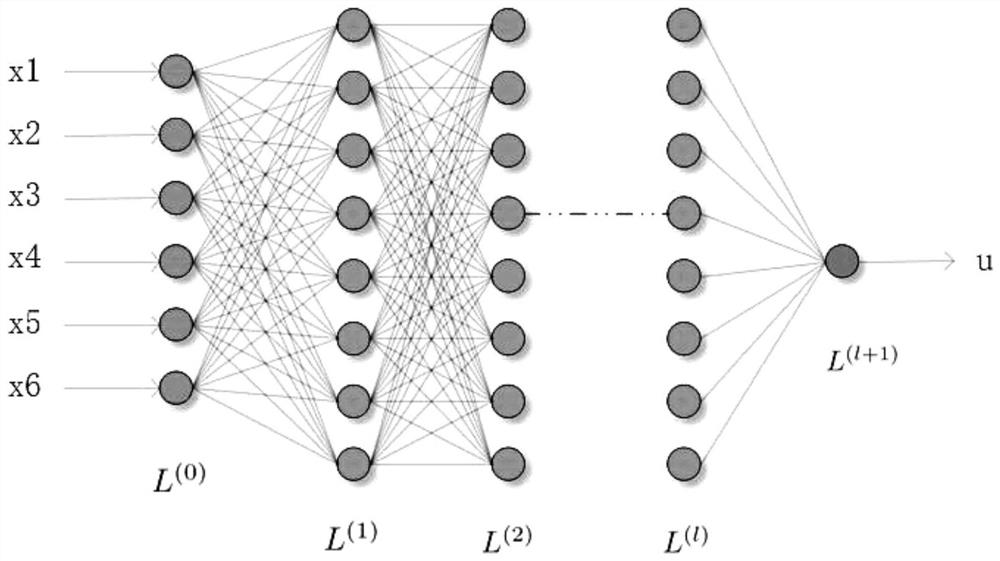

[0060] like Figure 1 to Figure 2 Shown is the embodiment of the injection molding machine deep neural network real-time optimal control method of the present invention, the existing injection molding machine includes servo amplifier, electro-hydraulic servo valve, injection head and screw, fuel injection nozzle and injection mold, each of the above components The connections are well known to those skilled in the art. If a voltage signal is applied to the servo amplifier, it converts the signal into a current proportional to the input voltage. Based on the applied current, the servo valve controls the hydraulic pressure in the injection cylinder, the pressure controls the dynamics of the plunger screw assembly, and the nozzle pressure in the nozzle chamber. Determines the fill rate. A kind of injection molding machine deep neural network real-time optimal control method of the present embodiment comprises the following steps:

[0061] S10. Establish a dynamic mathematical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com