Lead-free nuclear radiation protective gloves and preparation method thereof

A technology of protective gloves and anti-aging agent, which is applied in the direction of protective clothing, etc., can solve the problems of adding more auxiliary materials, environmental pollution, and less filling volume, achieve good weather resistance and mechanical properties, reduce production costs, and improve the yield of good products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment discloses the preparation method of lead-free nuclear radiation protection gloves of the present invention, specifically:

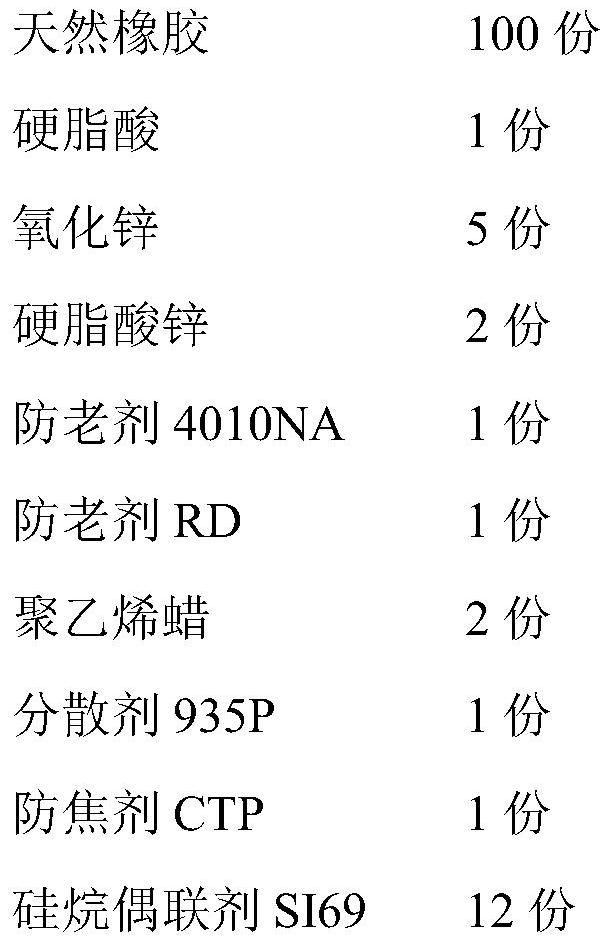

[0047] Raw material in the present embodiment is counted as by weight:

[0048]

[0049]

[0050] In this embodiment, the shielding functional filler is tungsten powder, which accounts for 60.7% of the total raw material mass.

[0051] Its preparation method is:

[0052] S1. Mastication: Weigh the amount of rubber formulated, put it on an open mill for mastication, and masticate until the film is uniform, transparent, and without mesh. The mastication temperature is 35°C and the time is 20 minutes.

[0053] S2. Mixing and calendering: After the plasticizing of raw rubber is completed, add active agent, anti-aging agent, processing aid, silane coupling agent SI69 for mixing. 35°C for 10 minutes;

[0054] After mixing evenly, add reinforcing agent, shielding functional filler, plasticizer, and continue mixing. After th...

Embodiment 2

[0058] The present embodiment discloses the preparation method of lead-free nuclear radiation protection gloves of the present invention, specifically:

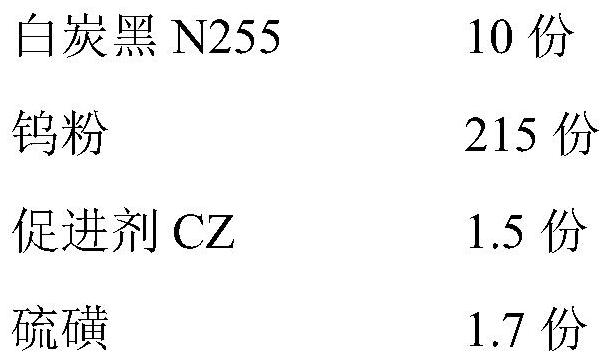

[0059] Raw material in the present embodiment is counted as by weight:

[0060]

[0061]

[0062] In this embodiment, the shielding functional filler is tungsten powder, which accounts for 75% of the total raw material mass.

[0063] Its preparation method is:

[0064] S1. Mastication: Weigh the amount of rubber in the formula, put it on an open mixer for mastication, and masticate until the film is uniform, transparent, and without mesh, and masticate at room temperature for 25 minutes.

[0065] S2. Mixing and calendering: After the plasticizing of raw rubber is completed, add active agent, anti-aging agent, processing aid, silane coupling agent SI69 for mixing. , the time is 8 minutes;

[0066] After mixing evenly, add reinforcing agent, shielding functional filler, plasticizer, and continue mixing. After adding ma...

Embodiment 3

[0070] The present embodiment discloses the preparation method of lead-free nuclear radiation protection gloves of the present invention, specifically:

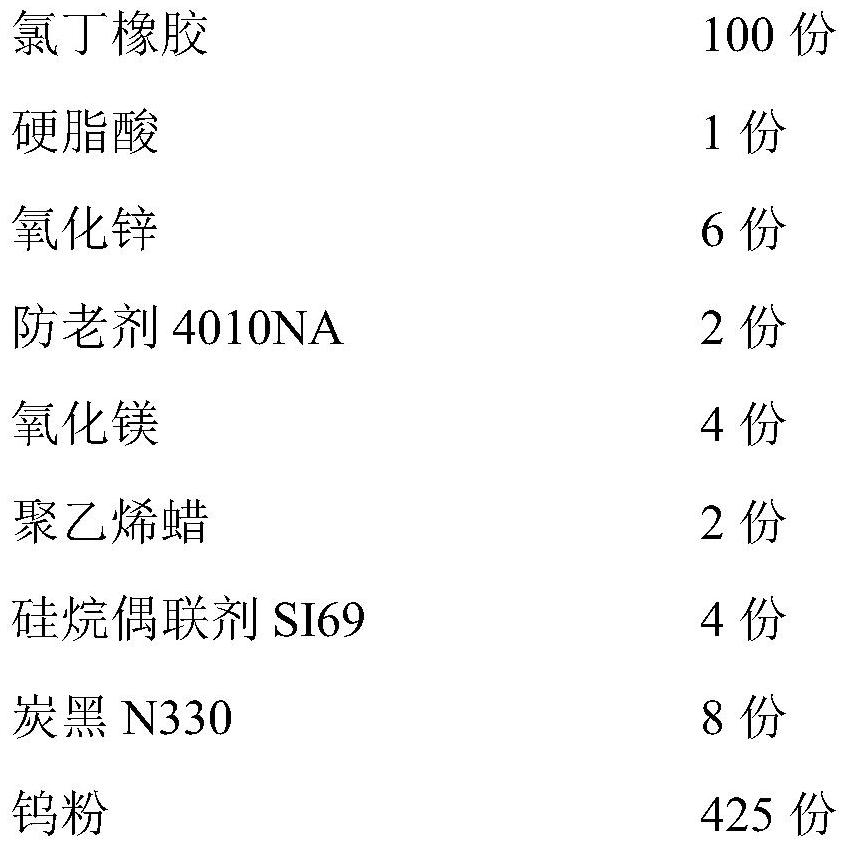

[0071] Raw material in the present embodiment is counted as by weight:

[0072]

[0073]

[0074] In this embodiment, the shielding functional filler is boron carbide and tungsten powder, boron carbide accounts for 30% of the total raw material mass, and tungsten accounts for 40% of the total raw material mass.

[0075] Its preparation method is:

[0076] S1. Mastication: Weigh the amount of rubber in the formula, put it on an open mill for mastication, and masticate until the film is uniform, transparent, and without mesh. The mastication temperature is 60°C and the time is 15 minutes.

[0077] S2. Mixing and calendering: After the plasticizing of raw rubber is completed, add active agent, anti-aging agent, processing aid, silane coupling agent SI69 for mixing. 60°C for 10 minutes;

[0078] After mixing evenly, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com