Polyolefin porous material, foam layer containing polyolefin porous material and adhesive tape containing polyolefin porous material

A porous material and polyolefin technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of heavy overall weight, inconvenient operation, and insufficient impact resistance, and achieve moderate softness and hardness, stable and reliable use , excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

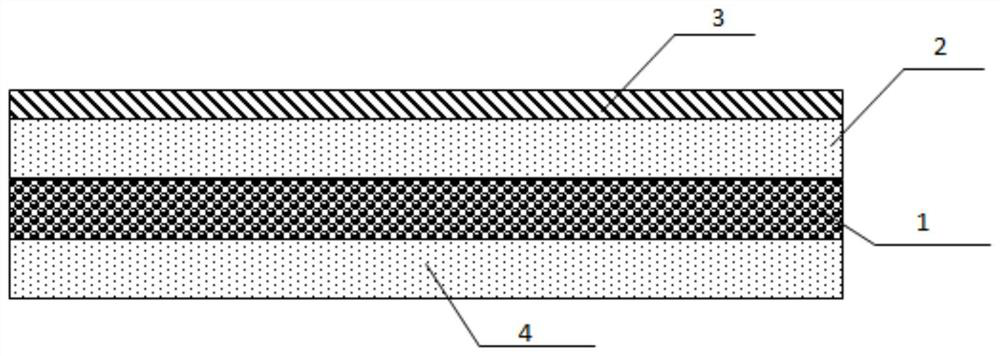

Image

Examples

preparation example Construction

[0046] The raw materials for the preparation of polyolefin porous materials include vinyl thermoplastic elastomers, low-density polyethylene, foaming agents, antioxidants, sensitizers and color masterbatches, of which vinyl thermoplastic elastomers, low-density polyethylene, foaming agents, The mass ratio of antioxidant, sensitizer and color masterbatch is 15~60:5~60:2~7:0.01~2:0.01~2:0.2~10, the color of polyolefin porous material is black or gray or white .

[0047] Blowing agent comprises physical blowing agent and chemical blowing agent, and wherein physical blowing agent comprises one or two in nitrogen, carbon dioxide, butane or expanded microspheres, or two or more; Preferred nitrogen or carbon dioxide, use physical blowing agent Foaming agent is produced by extrusion or molded foaming process;

[0048] Chemical blowing agents include azodicarbonamide, 2,2,2'-azobisisobutyronitrile, diisopropyl azodicarboxylate, barium azodicarboxylate, diethyl azodicarboxylate, azo A...

Embodiment 1

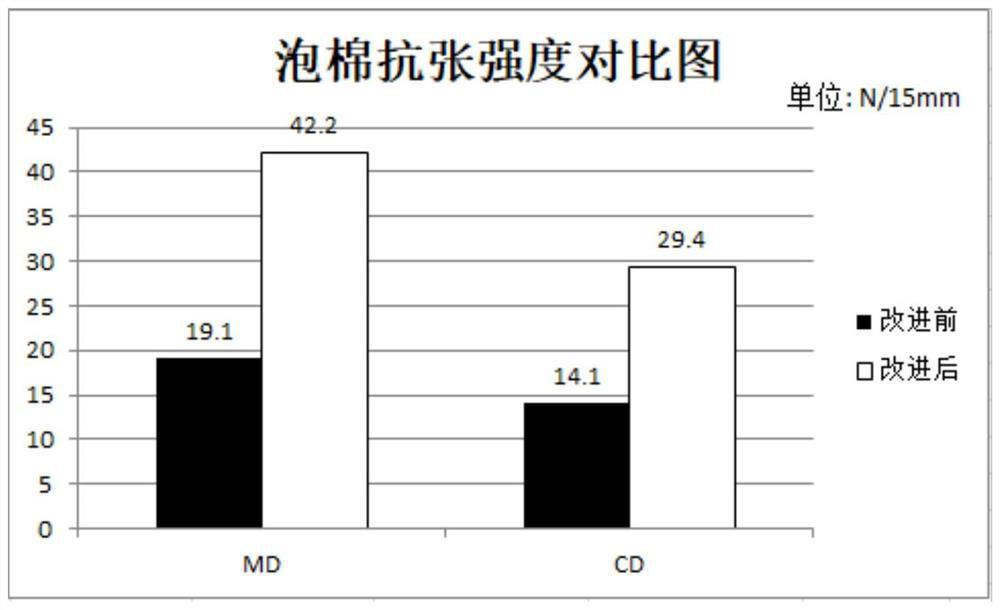

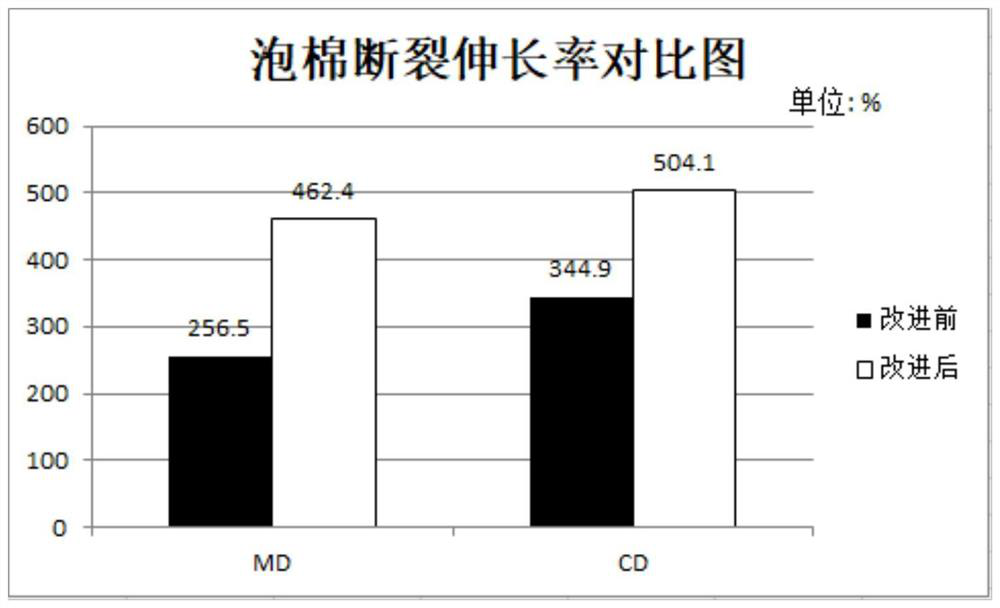

[0067] The mass ratio of vinyl thermoplastic elastomer, low density polyethylene, foaming agent, antioxidant, sensitizer and masterbatch is 38.2:52:4.2:0.2:0.4:5; the apparent density is 0.69g / cm 3 , the thickness is 0.17mm, the degree of crosslinking is 42%; the closed cell rate is 89%, the tensile strength MD is 42.2N / 15mm, and the CD is 29.4N / 15mm; the elongation MD is 462.4%, and the CD is 504.1%.

[0068] Such as Figure 2-Figure 6 As shown, in combination with the specific values of Example 1, the various data of the tape before improvement and the tape after improvement are compared through the experimental data table.

[0069] Note: if Figure 4 As shown, the bending test characterizes the warping height of the adherend after adhesion failure within a certain period of time. The smaller the value, the better the performance of the tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com