Water-based anti-doodling coating

An anti-graffiti, water-based technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient long-term effect and environmental protection, less VOC volatilization, and less solvent content of anti-graffiti coatings, and achieves weather resistance. Good effect, easy to remove, improve water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

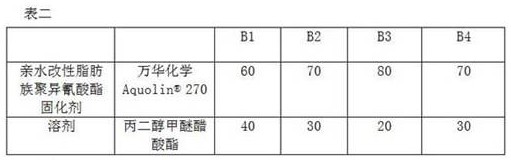

Examples

preparation example Construction

[0047] Preparation of component A:

[0048] (1) Preparation of film-forming substances: Add water-based hydroxyl polyacrylate dispersion and organosiloxane-modified water-based hydroxyl polyacrylic acid resin to the mixer at the same time according to the weight ratio, and stir at 1000r for 10 minutes to form film-forming substances. Don't need to be too fast, it is easy to generate air bubbles;

[0049] (2) Preparation of dispersion slurry: add deionized water according to the weight ratio, add dispersant, defoamer, gas silicon in turn at a stirring speed of 500r, and disperse for 10 minutes; then add pigments for 30 minutes of dispersing at a rotating speed of 2000r, After the fineness reaches 30 μm, filter to make dispersion slurry;

[0050] (3) Paint-forming stage: at a dispersion speed of 500r, mix the film-forming substance and dispersion slurry, disperse in a mixer at a speed of 1000r for 10 minutes, and then add film-forming aids, coupling agents, wetting agents, flow...

Embodiment 1

[0056] Example 1: A1:B1=5:1

Embodiment 2

[0057] Example 2: A1:B3 =7:1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com