Paste adhesive for cement-free single-component ceramic tile and production process of paste adhesive

A single-component, ceramic tile technology, applied in the direction of adhesive types, hydrocarbon copolymer adhesives, polymer adhesive additives, etc., can solve the problems of no way to guarantee quality, high comprehensive cost, and high raw material cost , to reduce the hidden dangers of life or property safety, good bonding performance and good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

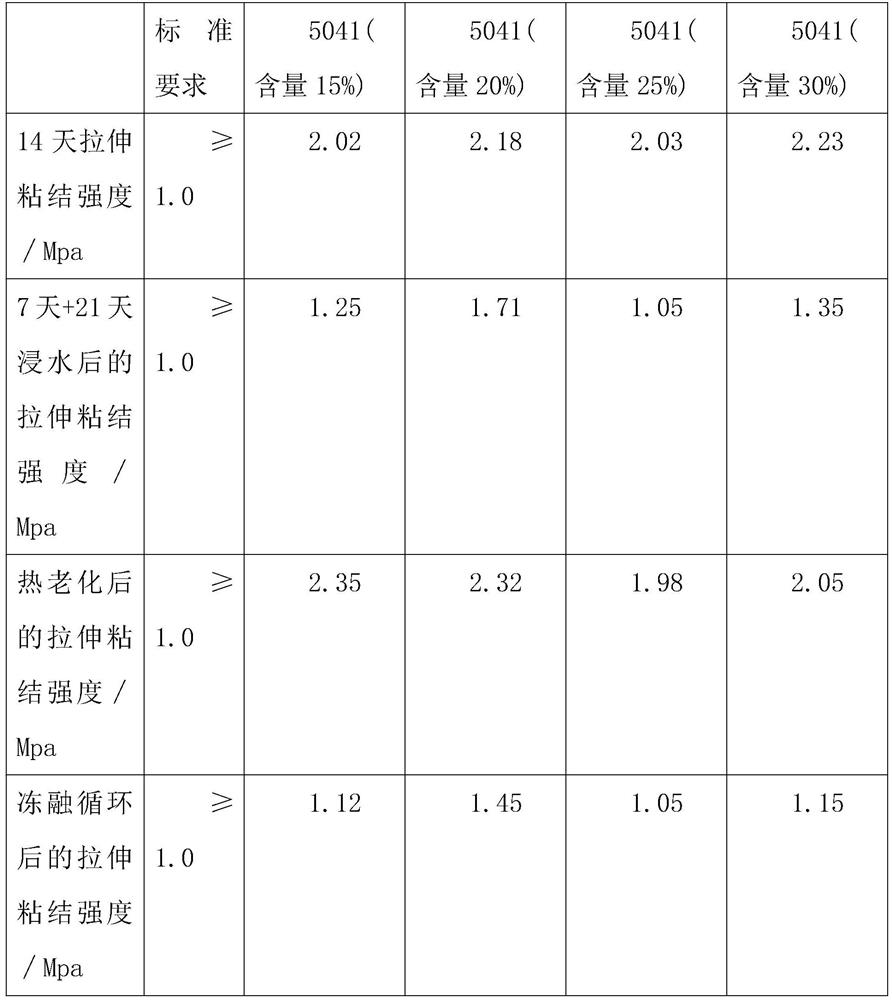

Embodiment 1

[0029] A cement-free single-component paste adhesive for ceramic tiles, comprising the following components in mass percentages:

[0030] Acronal 5041 15%, styrene-acrylic emulsion 10%, water-based tackifying resin 2.5%, dispersant 0.25, Rheovis HS 1169 0.15%, defoamer 0.15%, Omyacarb 5 40%, Sand 70-100 mesh quartz sand 20%, starch ether 0.05%, water retaining agent 0.3%, RheovisHS 1152 0.15%, preservative 0.2%, early strength agent 3%, epoxy resin 2.5%, leveling agent 0.15% and water.

[0031] The preservative is isothiazolone compound, the leveling agent is modified polysiloxane, the thickener is RheovisHS 1152, the defoamer is Foamaster MO2134, the dispersant is a mixture of Dispex CX 4320 and Dispex N40, and the early strength agent is Chlorine salt early strength agent.

[0032] A production process of cement-free one-component ceramic tile paste viscose, comprising the following steps:

[0033] First weigh and configure the raw materials, then directly put the water in...

Embodiment 2

[0038] A cement-free single-component paste adhesive for ceramic tiles, comprising the following components in mass percentages:

[0039] Acronal 5041 20%, styrene-acrylic emulsion 10%, water-based tackifying resin 2.5%, dispersant 0.25, Rheovis HS 1169 0.15%, defoamer 0.15%, Omyacarb 5 40%, Sand 70-100 mesh quartz sand 20%, starch ether 0.05%, water retaining agent 0.3%, RheovisHS 1152 0.15%, preservative 0.2%, early strength agent 3%, epoxy resin 2.5%, leveling agent 0.15% and water.

[0040]The preservative is isothiazolone compound, the leveling agent is modified polysiloxane, the thickener is RheovisHS 1152, the defoamer is Foamaster MO2134, the dispersant is a mixture of Dispex CX 4320 and Dispex N40, and the early strength agent is Chlorine salt early strength agent.

[0041] A production process of cement-free one-component ceramic tile paste viscose, comprising the following steps:

[0042] First weigh and configure the raw materials, then directly put the water in ...

Embodiment 3

[0047] A cement-free single-component paste adhesive for ceramic tiles, comprising the following components in mass percentages:

[0048] Acronal 5041 25%, styrene-acrylic emulsion 10%, water-based tackifying resin 2.5%, dispersant 0.25, Rheovis HS 1169 0.15%, defoamer 0.15%, Omyacarb 5 40%, Sand 70-100 mesh quartz sand 20%, starch ether 0.05%, water retaining agent 0.3%, RheovisHS 1152 0.15%, preservative 0.2%, early strength agent 3%, epoxy resin 2.5%, leveling agent 0.15% and water.

[0049] The preservative is isothiazolone compound, the leveling agent is modified polysiloxane, the thickener is RheovisHS 1152, the defoamer is Foamaster MO2134, the dispersant is a mixture of Dispex CX 4320 and Dispex N40, and the early strength agent is Chlorine salt early strength agent.

[0050] A production process of cement-free one-component ceramic tile paste viscose, comprising the following steps:

[0051] First weigh and configure the raw materials, then directly put the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com