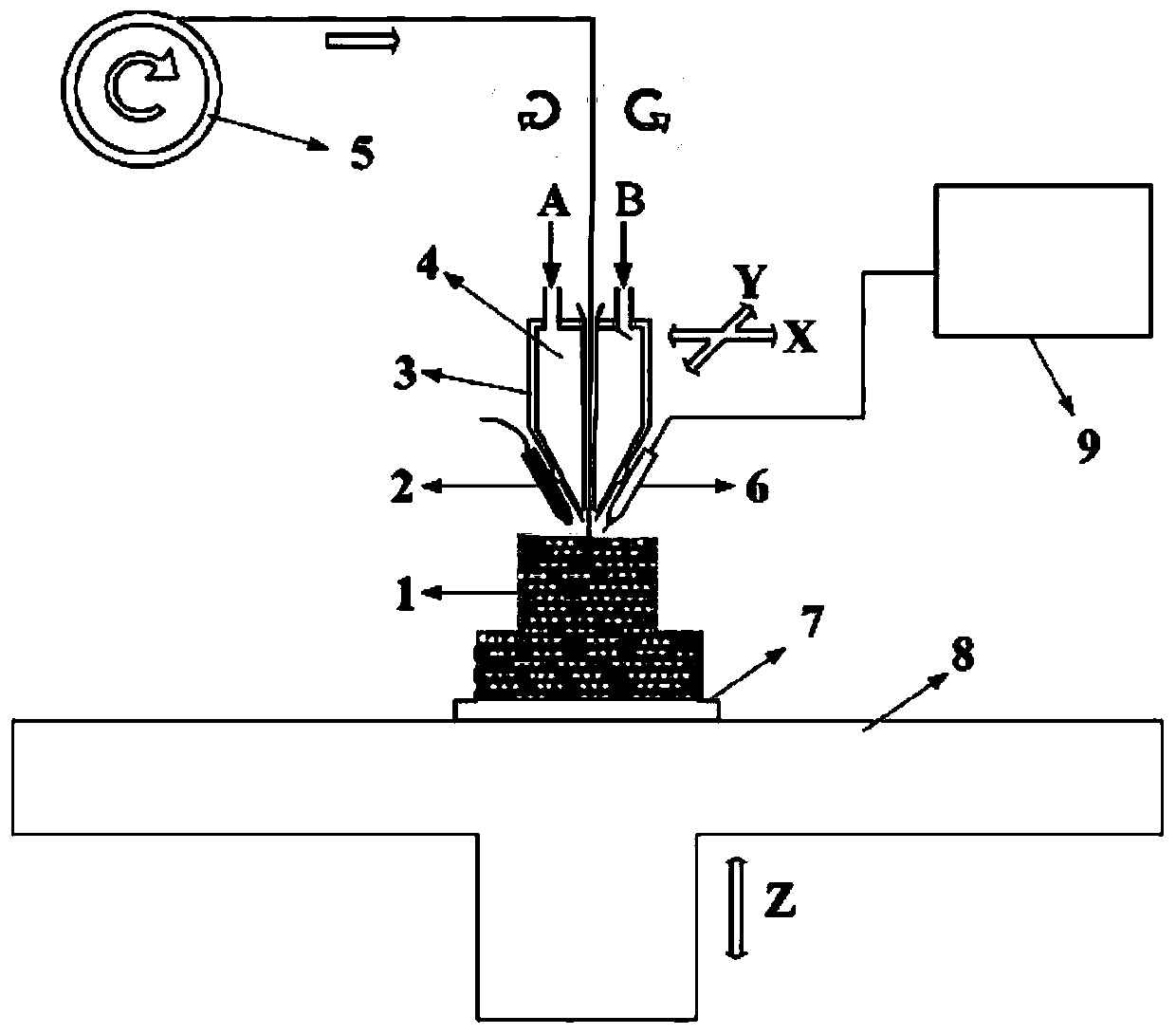

A method and device for forming fiber-reinforced ceramic matrix composites based on 3D printing technology

A ceramic matrix composite, 3D printing technology, applied in the field of 3D printing technology and ceramic sintering, can solve the problem of not considering the manufacturing method, and achieve the effect of high strength, high precision and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1), design the 3D model on the computer and convert it into a layered path file and import it into the 3D printer;

[0040] 2) After mixing acrylamide, N,N-methylenebisacrylamide, sodium polyacrylate and photocurable resin with a mass ratio of 24:1:7:40, add dendrite or ethylene glycol solvent, and stir Uniform, prepared into a resin-based premix with a concentration of 40%;

[0041] 3) Prepare ceramic powder according to the requirements of the parts to be printed. The ceramic powder is made of 2μm, 5μm, 40μm, and 100μm ceramic powders according to the performance requirements of the parts. The ceramic powder is made of alumina powder, and add 1% by mass fraction of magnesium oxide as a sintering aid;

[0042] 4), mixing and stirring tetramethylethylenediamine and deionized water evenly, and configuring it as a catalyst with a concentration of 60%;

[0043] 5) Add the powder into the premix liquid, and add the catalyst, fully stir and disperse to prepare a ceramic sl...

Embodiment 2

[0056] 1), design the 3D model on the computer and convert it into a layered path file and import it into the 3D printer;

[0057] 2) After mixing acrylamide, N,N-methylenebisacrylamide, sodium polyacrylate and photocurable resin with a mass ratio of 24:1:7:60, add dendrite or ethylene glycol solvent, and stir Uniform, prepared into a resin-based premix with a concentration of 60%;

[0058] 3) Prepare ceramic powder according to the requirements of the parts to be printed. The ceramic powder is made of 2μm, 5μm, 40μm, and 100μm ceramic powders according to the performance requirements of the parts. The ceramic powder is made of silicon oxide powder and added 5% mass fraction of yttrium oxide as sintering aid;

[0059] 4), mixing and stirring tetramethylethylenediamine and deionized water evenly, and configuring it as a catalyst with a concentration of 75%;

[0060] 5) Add the powder into the premix, and add the catalyst, fully stir and disperse to prepare a ceramic slurry wi...

Embodiment 3

[0073] 1), design the 3D model on the computer and convert it into a layered path file and import it into the 3D printer;

[0074] 2) After mixing acrylamide, N,N-methylenebisacrylamide, sodium polyacrylate and photocurable resin with a mass ratio of 24:1:7:50, add dendrite or ethylene glycol solvent, and stir Uniform, prepared into a resin-based premix with a concentration of 50%;

[0075] 3) Prepare ceramic powder according to the requirements of the parts to be printed. The ceramic powder is made of 2μm, 5μm, 40μm, and 100μm ceramic powders according to the performance requirements of the parts. The ceramic powder is made of silicon carbide powder and added 3% by mass fraction of magnesium oxide as a sintering aid;

[0076] 4), tetramethylethylenediamine and deionized water were mixed and stirred evenly, and configured as a catalyst with a concentration of 67%;

[0077] 5) Add the powder into the premix, and add the catalyst, fully stir and disperse to prepare a ceramic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com