Production method for cold-rolled acid-resistant steel 09CrCuSb

A production method and technology of acid-resistant steel, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of inability to meet the quality requirements of high-end users, rough surface quality, inaccurate dimensions, etc., and achieve excellent mechanical properties and smooth surface. , size-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

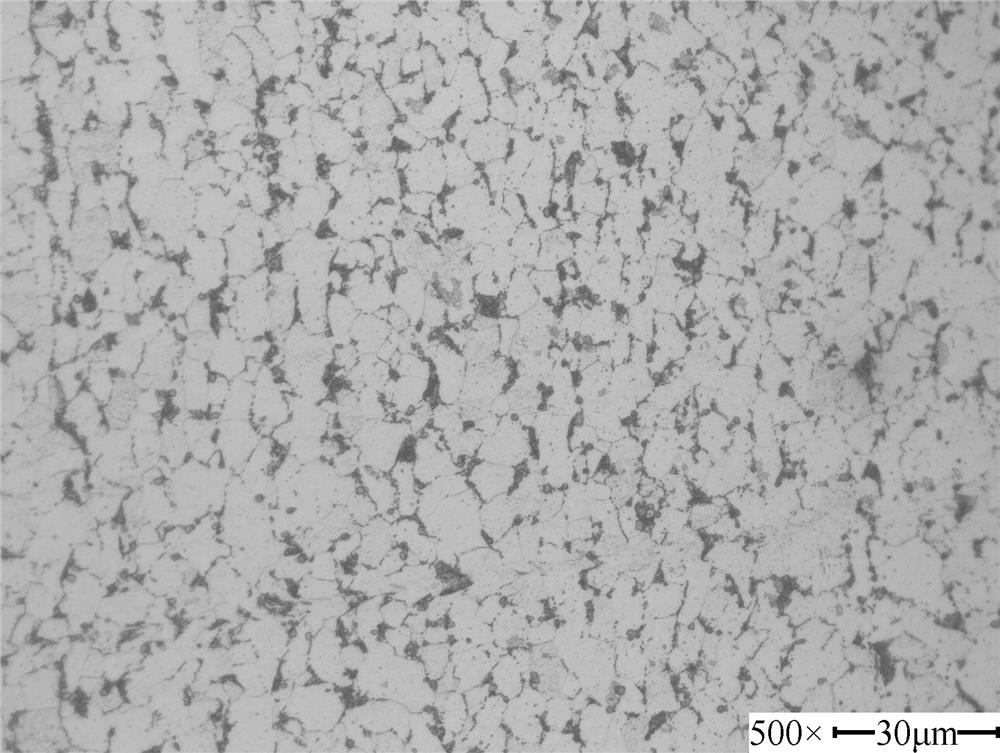

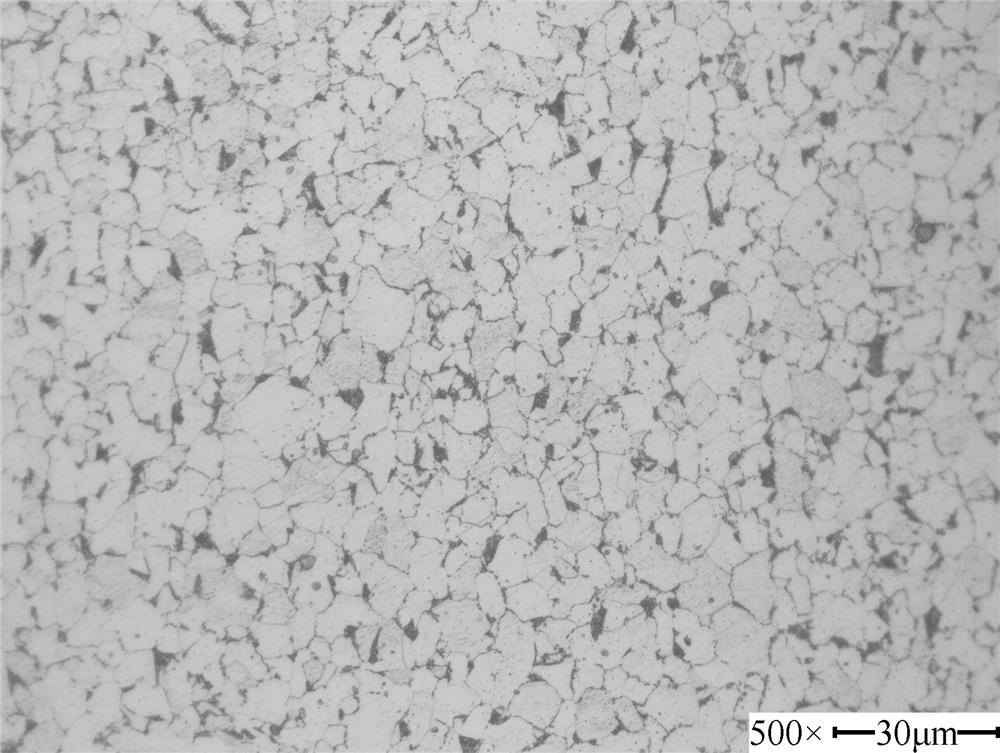

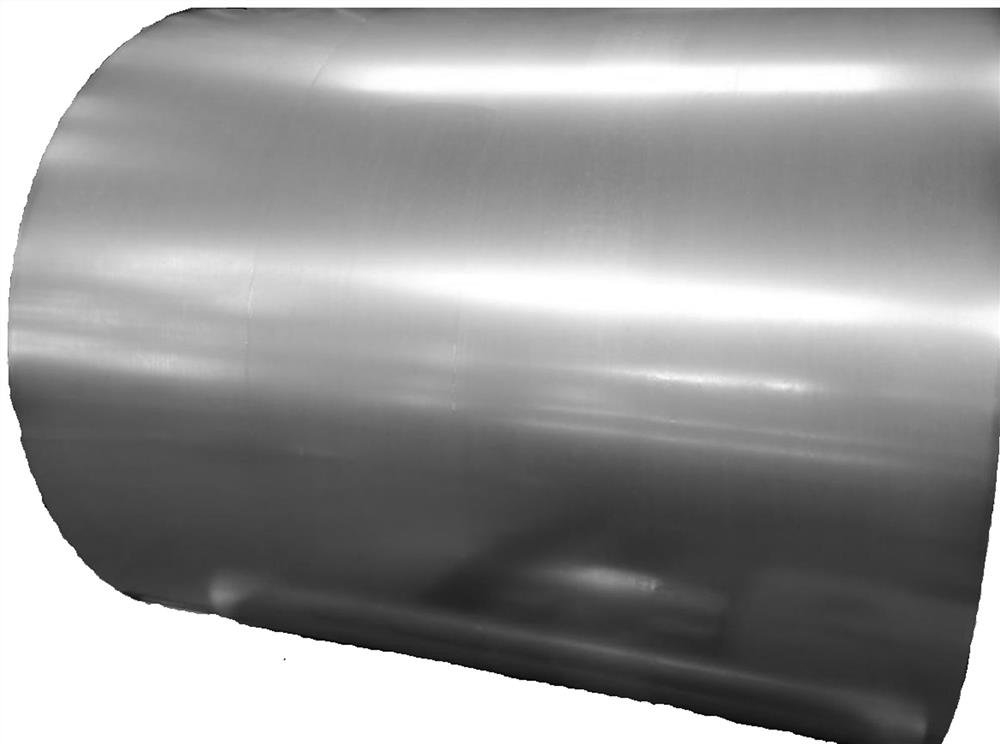

[0055] The transverse metallographic structure diagram and longitudinal metallographic structure diagram of the acid-resistant steel 09CrCuSb prepared in embodiment 1 are as follows figure 1 and 2 Shown, the acid-resistant steel prepared by embodiment 1 and the acid-resistant steel apparent quality of comparative example are as follows image 3 and 4 As shown, it can be seen that the apparent quality of the acid-resistant steel prepared in Example 1 is much higher than that of the acid-resistant steel of the comparative example.

[0056] Compared with hot-rolled acid-resistant steel, the thickness is thinner and the size is more accurate. The thickness of the finished product involves 0.5-2.0mm, the width accuracy can reach up to ±2mm, and the thickness accuracy can reach up to ±0.02mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com