Preparation method and application of high-performance cobalt-based oxygen evolution electrocatalytic nano material

A nanomaterial, electrocatalytic technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve problems such as large specific surface area, achieve high catalytic activity, promote electron transfer, and accelerate electron transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

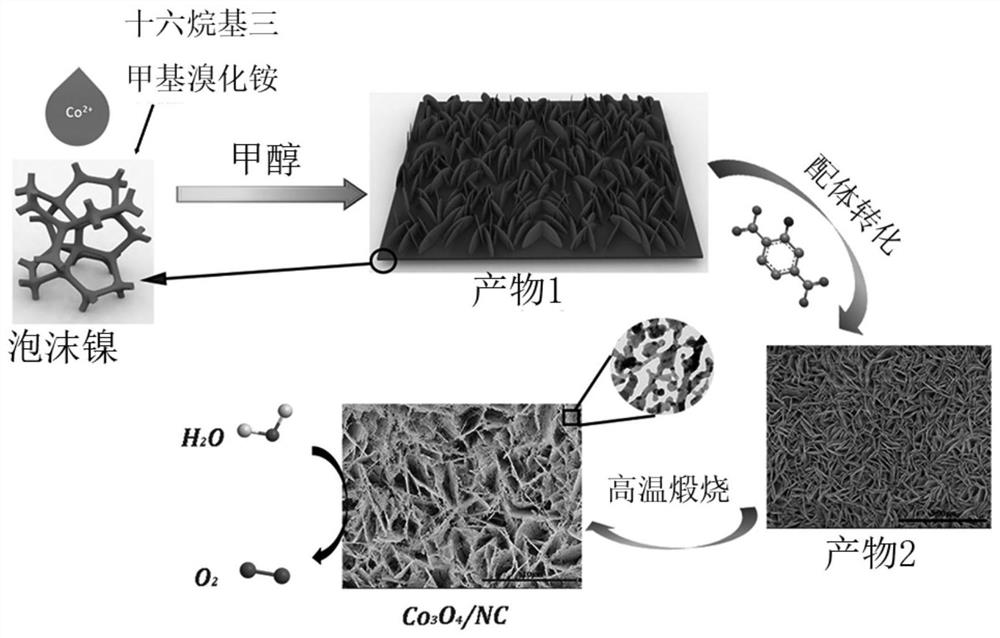

[0050] Embodiment 1, cobalt-based oxygen evolution electrocatalyst product 1 (Co 2 (OH) 3 Cl) Preparation

[0051] 1.5mmol of CoCl 2 ·6H 2 O and 1.5mmol of cetyltrimethylammonium bromide (CTAB) were added to a mixed solution of 6ml of deionized water and 30ml of methanol, ultrasonicated for 15min to obtain a clear solution, and transferred to a high-pressure reaction of 50ml of polytetrafluoroethylene in the cauldron. Take a 1cm×1cm pretreated nickel foam and immerse it, and react at 180°C for 24h. The foamed nickel material obtained by the reaction was repeatedly rinsed with deionized water, and finally dried in a vacuum oven at 60°C for 2 hours to obtain a lamellar product supported by foamed nickel with a structure of Co 2 (OH) 3 Cl.

Embodiment 2

[0052] Example 2, cobalt-based oxygen evolution electrocatalyst product 2 (CoMOF-NH 2 ) preparation

[0053] Get 0.5mmol o-aminoterephthalic acid (BDC-NH 2 ) into a 15ml polytetrafluoroethylene autoclave, and add 8ml of DMF and 1ml of deionized water in the mixed solvent, ultrasonic 15min to obtain a clear solution, the foam nickel prepared above was loaded with Co 2 (OH) 3 The Cl material was immersed in the above solution, the reaction tube was sealed, and the ligand conversion reaction was carried out at 100°C for 24h. The layered MOF structure material supported on the surface of nickel foam obtained by this solvothermal treatment was washed several times with deionized water, and finally dried in an oven at 60 °C for 6 hours. The product was labeled as CoMOF-NH 2 .

Embodiment 3

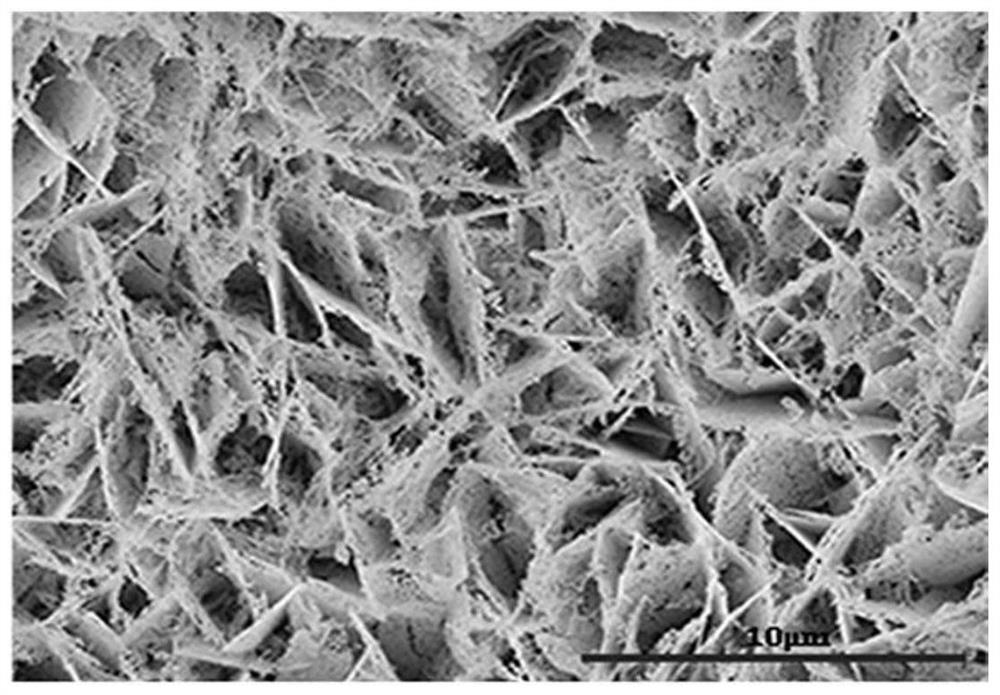

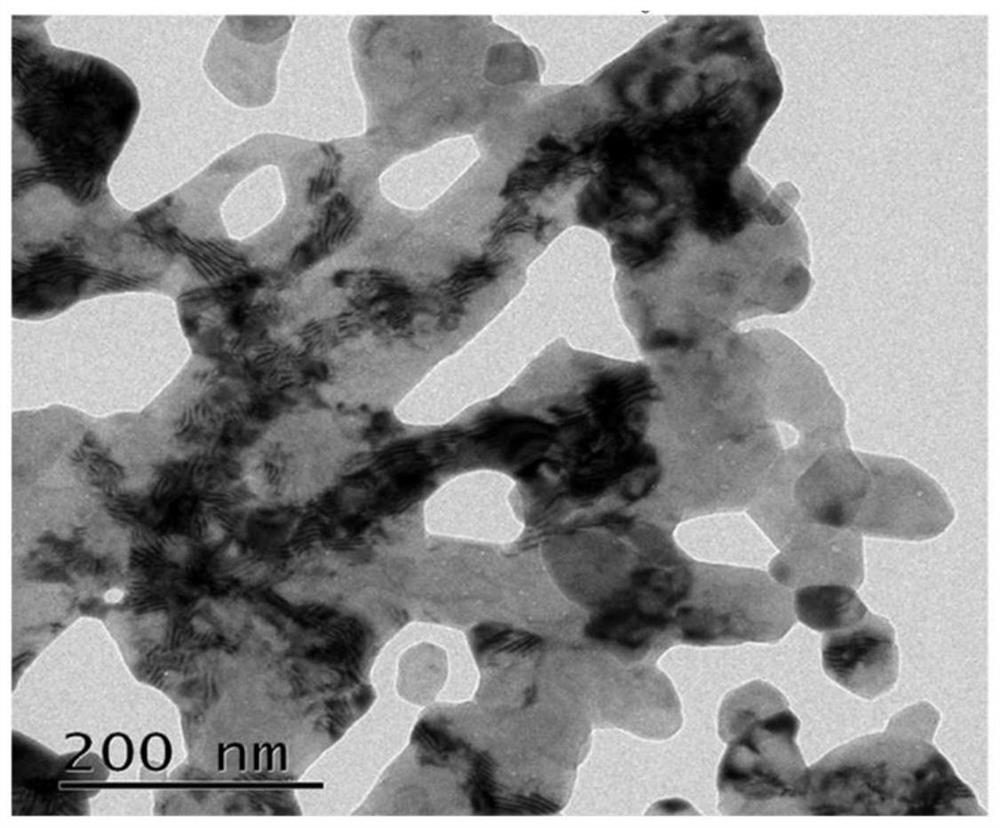

[0054] Embodiment 3, cobalt-based oxygen evolution electrocatalyst (Co 3 o 4 / NC) preparation

[0055] CoMOF-NH with layered MOF structure 2 Controlled heat treatment was performed under an argon atmosphere. The specific process is as follows: under an argon atmosphere (argon gas flow rate 80ml / min), first heat from room temperature to 600°C at a rate of 5° / min, keep at 600°C for 6 hours, and finally cool to room temperature at a rate of -5°C / min, get co 3 o 4 / NC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com