Optical fiber sensor based on high-purity quartz pressure sensitive element and preparation method thereof

A technology of optical fiber sensors and sensitive elements, applied in sensors, glass manufacturing equipment, fluid pressure measurement using optical methods, etc., can solve problems such as deterioration, inability to use at high temperatures, loosening or falling off of pressure sensitive elements, etc., and achieve the production process Simple, good stability, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

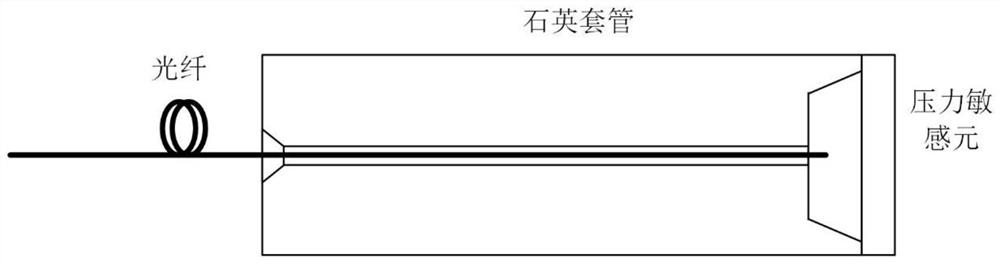

[0029] refer to figure 1 As shown, the present invention provides a kind of optical fiber sensor based on quartz pressure sensitive element, comprising optical fiber, quartz sleeve with trapezoidal pit, thin quartz pressure sensitive element, all quartz material constitutes optical fiber sensor, is suitable for removing hydrofluoric acid and 150 For harsh environments such as corrosion resistance other than hot phosphoric acid above ℃, the fixing of the quartz pressure sensitive element and the end face of the casing is fixed by laser hot melting without glue, which improves stability, reliability and scope of application, and before laser hot melting Temporarily fix the glass pressure sensitive element on the end face of the sleeve by optical glue, the end face of the optical fiber fixed in the quartz sleeve and the inner surface of the glass pressure sensitive element form a Fabry-Perot cavity; the thickness of the quartz pressure sensitive element is determined by optical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com