Complete pellet feed for fattening sheep and preparation method of complete pellet feed

A technology of pellet feed and fattening sheep, which is applied in the field of full-price pellet feed for fattening sheep and its preparation, can solve the problems of reducing the immunity and intestinal digestion function of sheep, reducing the breeding benefits of fattening sheep, and high feed costs for fattening sheep. Achieve the effects of enhancing the body's immunity and intestinal digestion, reducing labor input and improving growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of full price pellet feed for fattening sheep; comprising the following steps:

[0060] (1) Take each raw material according to the proportioning ratio;

[0061] (2) Pretreatment, mixing and packaging are carried out according to the production process requirements.

Embodiment 1

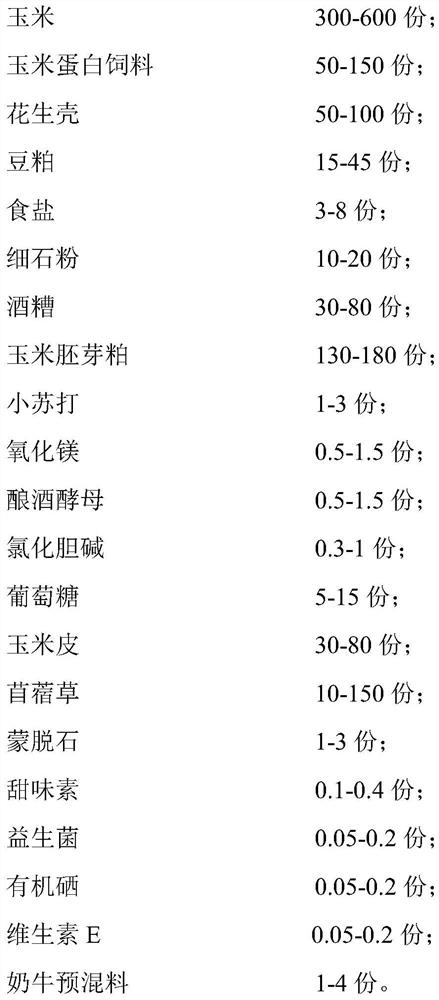

[0063] A full-price pellet feed for fattening sheep is characterized in that it consists of the following components by weight:

[0064] 300 parts of corn;

[0065] 50 parts of corn gluten feed;

[0066] 50 parts of peanut shells;

[0067] 15 parts of soybean meal;

[0068] 3 parts table salt;

[0069] 10 parts of fine stone powder;

[0070] 30 parts distiller's grains;

[0071] 130 parts of corn germ meal;

[0072] 1 part baking soda;

[0073] 0.5 parts of magnesium oxide;

[0074] 0.5 parts of Saccharomyces cerevisiae;

[0075] 0.3 parts of choline chloride;

[0076] 5 parts of glucose;

[0077] 30 parts corn husk;

[0078] 10 parts of alfalfa;

[0079] 1 part of montmorillonite;

[0080] Sweetener 0.1 part;

[0081] 0.05 parts of probiotics;

[0082] 0.05 parts of organic selenium;

[0083] 0.05 parts of vitamin E;

[0084] Dairy cow premix 1 part.

[0085] Dairy cow premix consists of vitamin premix and mineral premix.

[0086] The vitamin premix consist...

Embodiment 2

[0092] A full-price pellet feed for fattening sheep is characterized in that it consists of the following components by weight:

[0093] 600 parts of corn;

[0094] 150 parts of corn gluten feed;

[0095] 100 parts of peanut shells;

[0096] 45 parts of soybean meal;

[0097] 8 portions of table salt;

[0098] 20 parts of fine stone powder;

[0099] 80 parts distiller's grains;

[0100] 180 parts of corn germ meal;

[0101] 3 parts baking soda;

[0102] 1.5 parts of magnesium oxide;

[0103] 1.5 parts of Saccharomyces cerevisiae;

[0104] Choline chloride 1 part;

[0105] 15 parts of glucose;

[0106] 80 parts corn husk;

[0107] 150 parts of alfalfa;

[0108] 3 parts of montmorillonite;

[0109] 0.4 part sweetener;

[0110] 0.2 parts of probiotics;

[0111] 0.2 parts of organic selenium;

[0112] 0.2 parts of vitamin E;

[0113] 4 servings of dairy cow premix.

[0114] Dairy cow premix consists of vitamin premix and mineral premix.

[0115] The vitamin premix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com