Household garbage resource utilization method

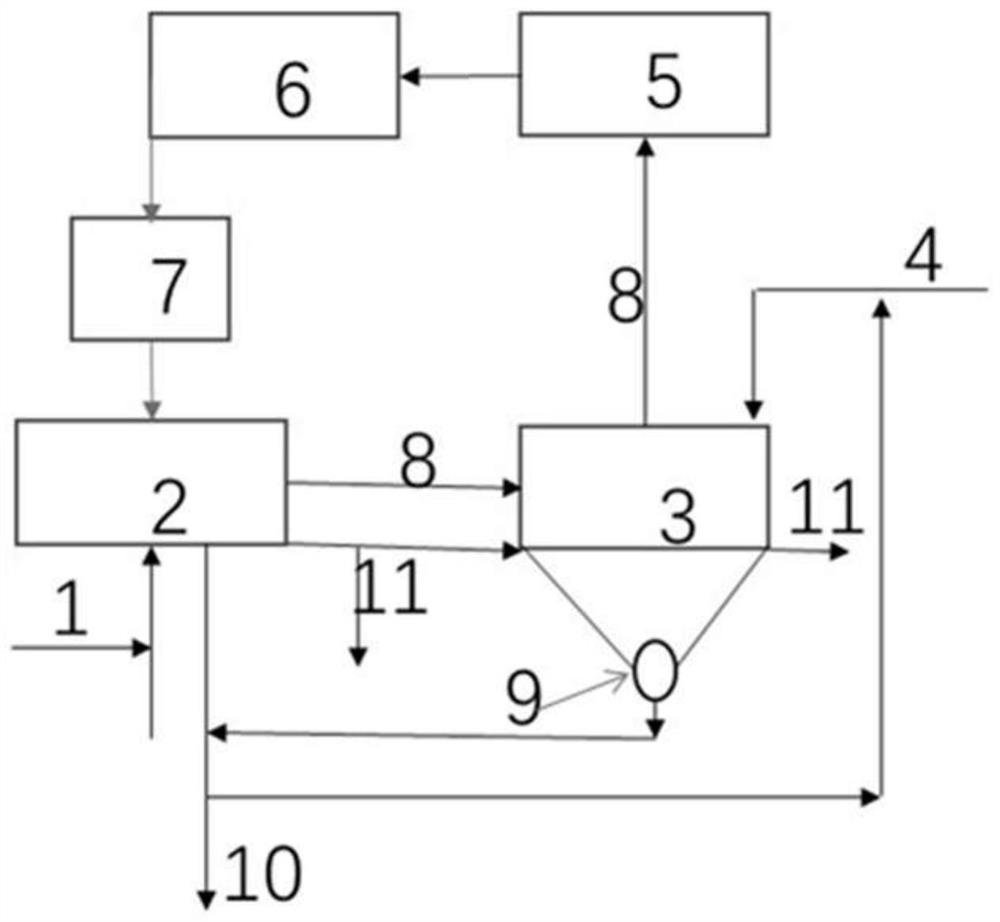

A domestic garbage and resource recovery technology, applied in the field of waste treatment and resource recovery, can solve problems such as high operating costs, difficult online monitoring, and small scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

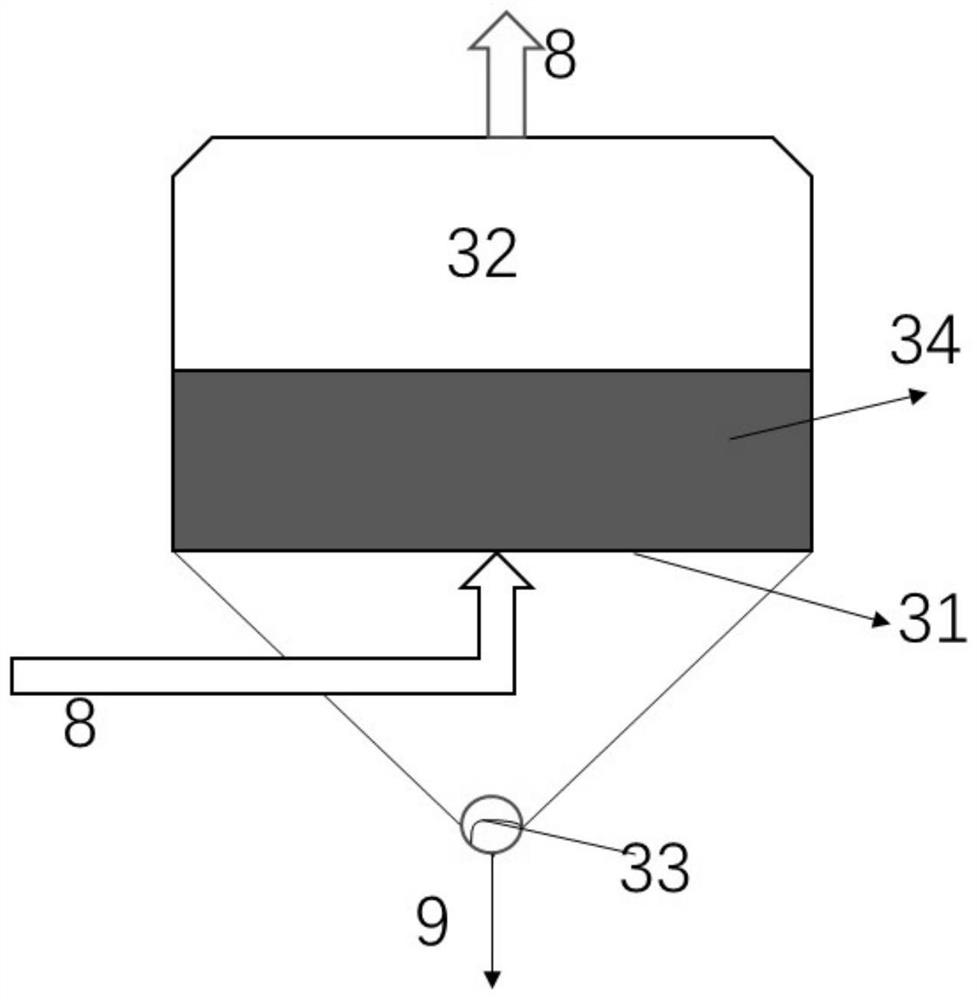

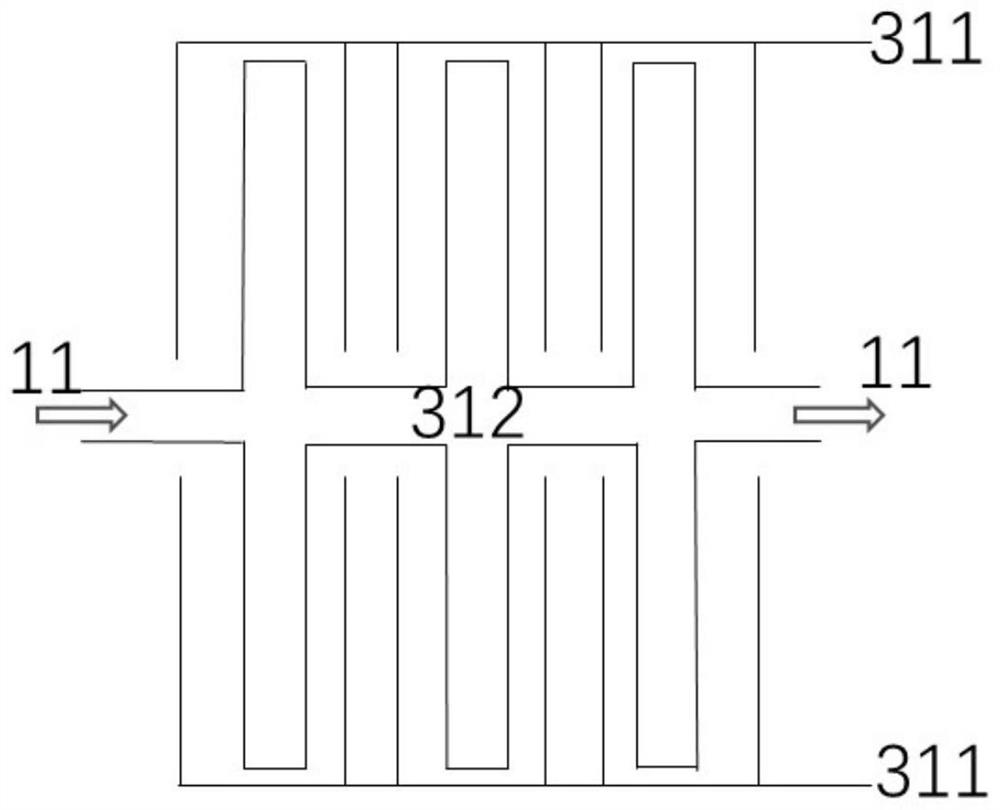

[0068] In a small town with a population of 8,000, the output of domestic waste is 5.6t / d, and the transportation distance from the county is relatively long. After classified collection, there are 3 tons / d of combustible garbage 1 and 2 tons / d of kitchen waste 4. Adopt the technology of the present invention to process, adopt the pyrolysis device 2 of propulsion type, carry out continuous pyrolysis to combustible garbage 1, produce volatile matter 8 and be 188m at 550-600 ℃ 3 / h, 62.5Nm under standard condition 3 / h, the water content of kitchen waste 4 is about 80%, and the specific gravity is 0.91t / m 3 After normal operation, 38% of the pyrolytic charcoal 10 discharged from the pyrolysis device 2 is mixed with the kitchen waste 4, and then spread on the surface of the kitchen waste pile 34 in two stages.

[0069] The thickness of the kitchen waste pile layer 34 is normally stable within the range of 350-450mm. The temperature in the drying device 3 is about 60-70°C in wi...

Embodiment 2

[0073] For a township with a population of 20,000, the domestic waste output is 19t / d. After classified collection, there are 11 tons / d of combustible garbage and 7.5 tons / d of kitchen waste. The technology of the present invention is used for processing, and a screw propulsion pyrolysis device is used to continuously pyrolyze combustible garbage, and the volatile matter produced is 691m at 550-600°C 3 / h, 229.2Nm under standard condition 3 / h, the water content of combustible garbage is about 81%, and the specific gravity is 0.92t / m 3 . After normal operation, 40% of the charcoal in the pyrolysis device is mixed with kitchen waste, and then spread on the surface of the combustible waste pile in two stages. The thickness of the kitchen waste pile is normally stable within the range of 350-450mm. The temperature in the drying device is about 60-70°C in winter and about 82-95°C in summer.

[0074] The volatile matter produced by the pyrolysis device is sent to the lower part...

Embodiment 3

[0077] In a medium-sized town with a population of 50,000, the output of domestic waste is 40t / d, and the transportation distance from the county seat is relatively long. After classified collection, there are 24 tons / d of combustible garbage and 16 tons / d of kitchen waste. The technology of the present invention is used for processing, and a screw propulsion pyrolysis device is used to continuously pyrolyze combustible garbage, and the volatile matter produced is 1508m at 550-600°C 3 / h, 500Nm under standard condition 3 / h or so, the water content of kitchen waste is about 82%, and the specific gravity is 0.94t / m 3 .

[0078] After normal operation, 40% of the charcoal in the pyrolysis unit is mixed with wet garbage, and then spread on the surface of the combustible garbage pile 3 times a day. The thickness of the kitchen waste pile is normally stable within the range of 300-400mm. The temperature in the drying device is about 60-70°C in winter and about 82-95°C in summer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com