Porous ceramic material pore-forming agent and preparation method thereof

A technology of porous ceramics and pore-forming agent, which is applied in the field of porous ceramic material pore-forming agent and its preparation, can solve the problems of difficult removal of inorganic pore-forming agent, difficulty in maintaining pore shape, influence of ceramic main body, etc., and achieves low cost and acceptable shape. Control, no bad residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

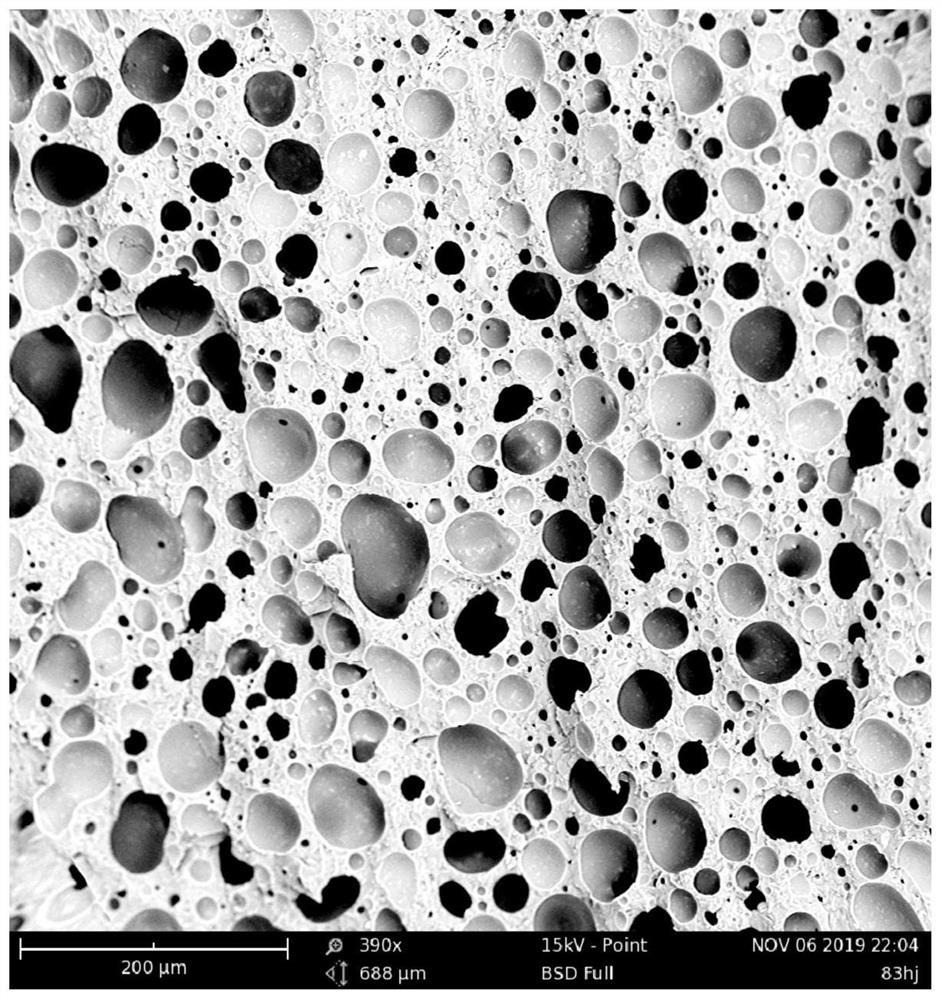

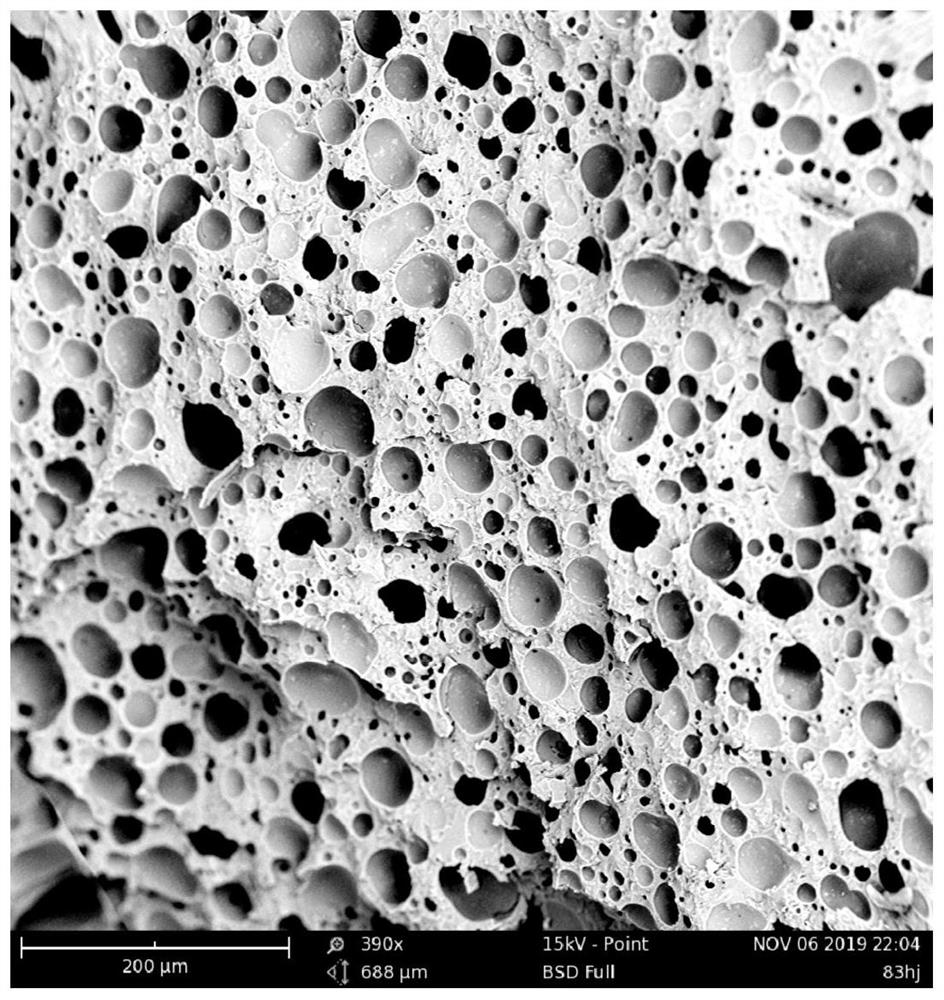

Image

Examples

Embodiment 1

[0033] (1) heat-treat rice husks at 600° C. for 4 hours in an air atmosphere, and cool to room temperature with the furnace to obtain the first product;

[0034] (2) Put the first product into a planetary ball mill for crushing, then pass through a 5000-mesh sieve to obtain the second product;

[0035] (3) The second product is spray-dried and granulated, first passed through a 300-mesh sieve, and then passed through a 325-mesh material, and the obtained non-permeable material is the porous ceramic material with a particle size of 40-50 μm for pore making The agent is detected by X-ray photoelectron spectroscopy and consists of: carbon 27wt%, silicon dioxide 67.4wt%, calcium chloride 2.2wt%, ferric chloride 0.1wt% and potassium chloride 3.3wt%; the planetary formula The parameters of the ball mill are: the distribution balls are 6mm ceramic balls, the speed ratio: rotation:revolution is 2:1, the revolution speed is 200rpm, and the ball milling time is 12h; The feed speed is 5...

Embodiment 2

[0038] (1) heat-treat rice husks at 600°C for 2.5 hours in an air atmosphere, and cool to room temperature with the furnace to obtain the first product;

[0039] (2) Put the first product into a planetary ball mill for crushing, then pass through a 5000-mesh sieve to obtain the second product;

[0040] (3) The second product is spray-dried and granulated, first passed through a 300-mesh sieve, and then passed through a 325-mesh material, and the obtained non-permeable material is the porous ceramic material with a particle size of 40-50 μm for pore making The agent is detected by X-ray photoelectron spectroscopy and consists of: carbon 28wt%, silicon dioxide 66.4wt%, calcium chloride 2.18wt%, ferric chloride 0.12wt% and potassium chloride 3.3wt%; the above-mentioned planet The parameters of the type ball mill are: the matching balls are 6mm ceramic balls, the speed ratio: rotation:revolution is 2:1, the revolution speed is 200rpm, and the ball milling time is 12h; the process ...

Embodiment 3

[0043] (1) heat-treat rice husks at 600° C. for 1 hour in an air atmosphere, and cool to room temperature with the furnace to obtain the first product;

[0044] (2) Put the first product into a planetary ball mill for crushing, then pass through a 5000-mesh sieve to obtain the second product;

[0045] (3) The second product is spray-dried and granulated, first passed through a 300-mesh sieve, and then passed through a 325-mesh material, and the obtained non-permeable material is the porous ceramic material with a particle size of 40-50 μm for pore making Agent, which is composed of 28.5wt% carbon, 65.9wt% silicon dioxide, 2.18wt% calcium chloride, 0.12wt% iron trichloride and 3.3wt% potassium chloride by X-ray photoelectron spectroscopy; The parameters of the type ball mill are: the matching balls are 6mm ceramic balls, the speed ratio: rotation:revolution is 2:1, the revolution speed is 200rpm, and the ball milling time is 12h; the process parameters of the above spray drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com