Preparation method of acetoxime

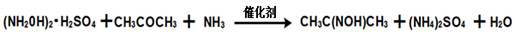

A technology of acetone oxime and acetone, applied in the field of preparation of acetone oxime, can solve the problems of long reaction time and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

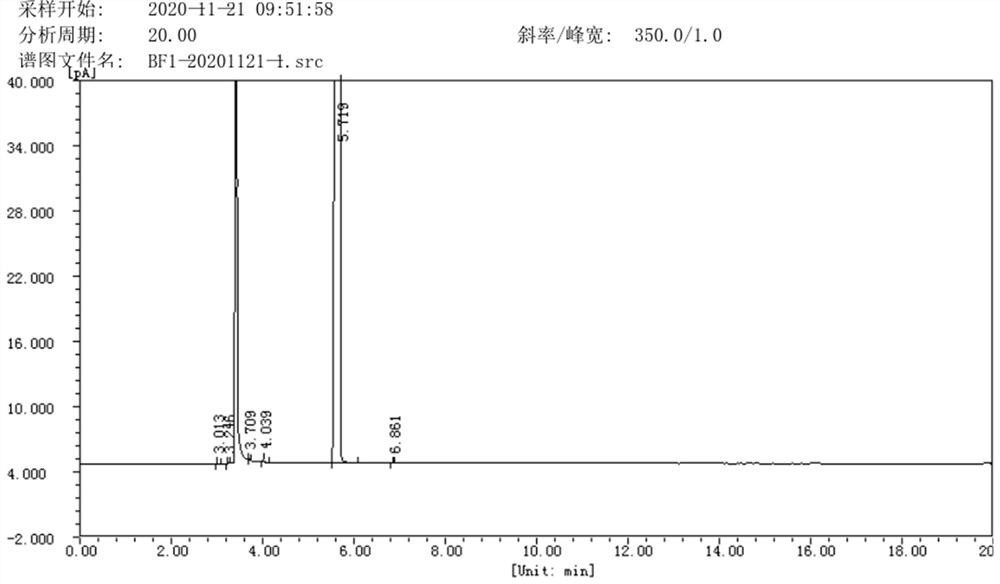

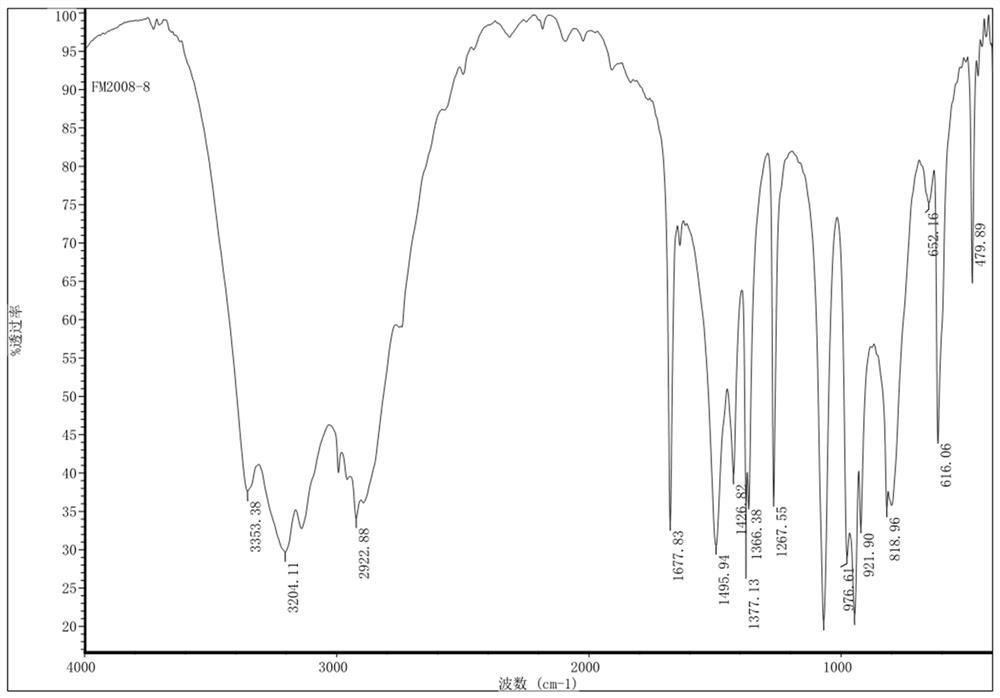

Embodiment 1

[0039] A kind of preparation method of acetone oxime, its operation step is:

[0040] Step 1, oximation reaction, 58kg acetone, 21kg ammonia gas, 0.05kg catalyst and 920kg mass percentage concentration are 18% hydroxylamine sulfate solution to add in the mixer, then enter in the oximation reactor after cooling through the cooler, control Temperature 40°C, cyclic reaction for 60 minutes, the reaction liquid in the oximation reactor overflows to the oximation separator for stratification, the upper layer is the acetone oxime organic phase, and the lower layer is the ammonium sulfate mother liquor;

[0041] Step 2, stripping and separation, the ammonium sulfate mother liquor from the oximation separator enters the stripping tower for stripping, and recovers organic substances such as acetone oxime in the ammonium sulfate mother liquor, and the organic phase at the top of the tower is pumped to the oximation reactor circulation pump Imported recycling, the stripping temperature is...

Embodiment 2

[0054] A kind of preparation method of acetone oxime, its operation step is:

[0055] Step 1, oximation reaction, 64kg acetone, 27kg ammonia gas, 1.4kg catalyst and 1400kg mass percent concentration are 22% hydroxylamine sulfate solution and add in the mixer, then enter in the oximation reactor after cooling through the cooler, control Temperature at 50°C, cyclic reaction for 120 minutes, the reaction liquid in the oximation reactor overflows to the oximation separator for stratification, the upper layer is the acetone oxime organic phase, and the lower layer is the ammonium sulfate mother liquor;

[0056] Step 2, stripping and separation, the ammonium sulfate mother liquor from the oximation separator enters the stripping tower for stripping, and recovers organic substances such as acetone oxime in the ammonium sulfate mother liquor, and the organic phase at the top of the tower is pumped to the oximation reactor circulation pump Imported recycling, the stripping temperature ...

Embodiment 3

[0069] A kind of preparation method of acetone oxime, its operation step is:

[0070] Step 1, oximation reaction, 72kg of acetone, 32kg of ammonia, 3kg of catalyst and 1800kg of hydroxylamine sulfate solution with a mass percentage concentration of 24% are added to the mixer, and then enter the oximation reactor after being cooled by a cooler, and the temperature is controlled 60°C, cyclic reaction for 180 minutes, the reaction liquid in the oximation reactor overflows to the oximation separator for stratification, the upper layer is the organic phase of acetone oxime, and the lower layer is the mother liquor of ammonium sulfate;

[0071] Step 2, stripping and separation, the ammonium sulfate mother liquor from the oximation separator enters the stripping tower for stripping, and recovers organic substances such as acetone oxime in the ammonium sulfate mother liquor, and the organic phase at the top of the tower is pumped to the oximation reactor circulation pump Imported recy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com