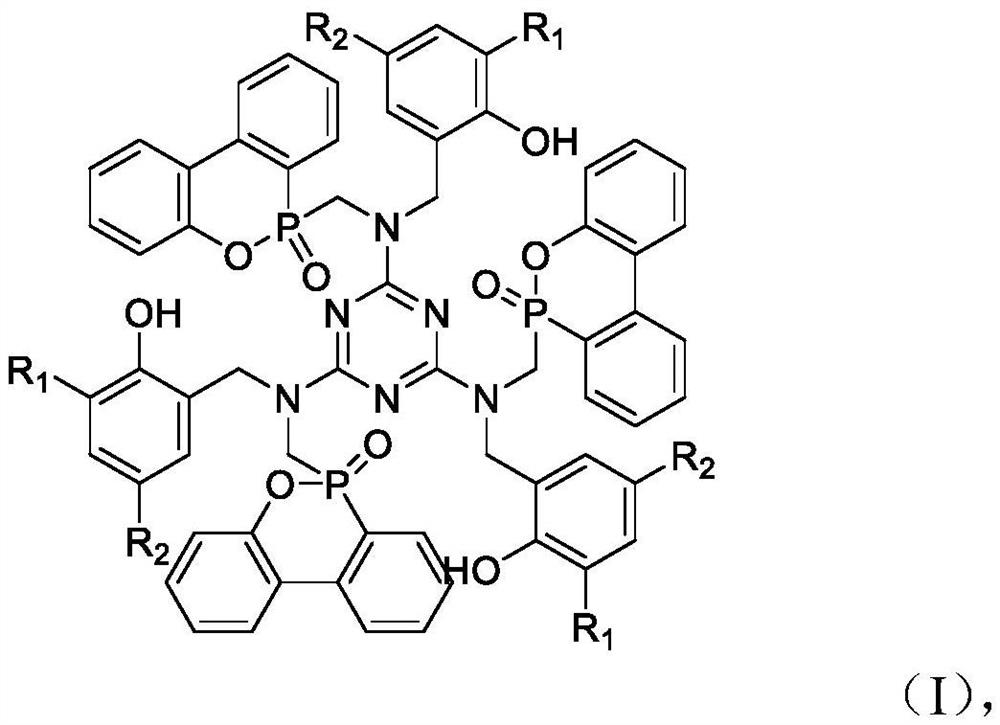

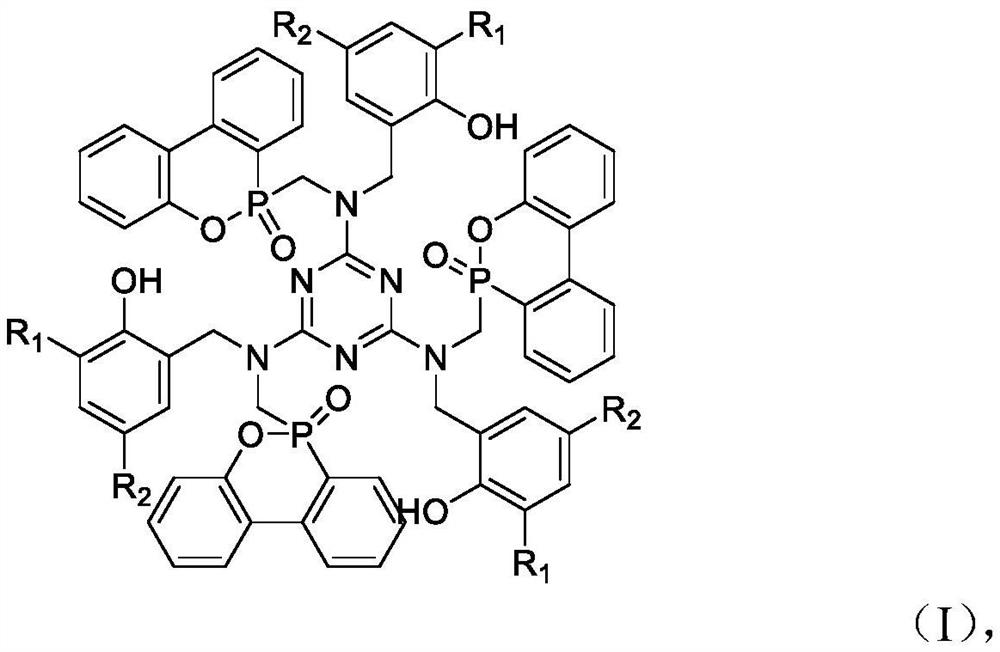

Melamine-based nitrogen and phosphorus-containing compound, preparation method and application thereof, and flame-retardant epoxy resin composition of melamine-based nitrogen and phosphorus-containing compound

A melamine-based and melamine-based benzene technology is applied in the field of melamine-based nitrogen-containing phosphorus compounds and can solve the problems of flammability of epoxy resins and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] R 1 is a hydrogen atom, R 2 The synthetic steps of the melamine-based nitrogen-containing phosphorus compound of hydrogen atom are as follows:

[0040] 7.77g melamine (commercially available), 12.21g paraformaldehyde (commercially available), and 17.39g phenol (commercially available) were added to a three-necked flask with a stirring device, and a certain amount of triethylamine (commercially available) was added dropwise to adjust pH to 9, under stirring and 100 ℃ temperature condition, carry out reaction 5h, after completion of reaction, vacuum drying obtains intermediate product; Then, 19.2g above-mentioned intermediate and 30.24g DOPO (commercially available) (the molar ratio of intermediate and DOPO 1:3) into a three-necked flask with a stirring device, and add solvent 250g THF, stir and react at a temperature of 40°C for 24h, after the reaction is complete, cool, filter and wash, and vacuum dry to obtain powdered melamine base Nitrogen-containing phosphorus com...

Embodiment 2

[0049] R1 is a hydrogen atom, and R2 is the synthesis steps of the melamine-based nitrogen-containing phosphorus compound of methyl as follows:

[0050] 7.77g melamine (commercially available), 12.21g paraformaldehyde (commercially available), 19.98g 4-methylphenol (commercially available) are added in the there-necked flask with stirring device, drop a certain amount of triethylamine ( Commercially available) adjust the pH to 9, react under stirring and 100°C temperature conditions for 6h, after the reaction is completed, vacuum dry to obtain the intermediate product; then, 20.88g of the above intermediate and 30.24g of DOPO (commercially available) (intermediate The molar ratio to DOPO is 1:3) into a three-necked flask with a stirring device, and a solvent of 250g THF (commercially available), stirred and reacted at a temperature of 40°C for 24h, after the reaction was complete, cooled, filtered and washed , to obtain powdery melamine-based nitrogen-containing phosphorus com...

Embodiment 3

[0059] R1 is a methyl group, and R2 is a melamine-based nitrogen-containing phosphorus compound synthetic step of a methyl group as follows:

[0060] 7.77g melamine (commercially available), 12.21g paraformaldehyde (commercially available), 22.57g 2,4-xylenol (commercially available) were added in a three-necked flask with a stirring device, and a certain amount of three Ethylamine (commercially available) was used to adjust the pH to 9, and the reaction was carried out under stirring and at a temperature of 100° C. for 8 h. After the reaction was completed, the intermediate product was obtained by vacuum drying; then, 22.56 g of the above intermediate and 30.24 g of DOPO (commercially available) (The molar ratio of the intermediate to DOPO is 1:3) into a three-necked flask with a stirring device, and add a solvent of 250g THF (commercially available), stir and react at a temperature of 40°C for 24h, after the reaction is complete, cool, Suction filtration, washing, and vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com