Polyethylene resin for hollow product, and composition and preparation method thereof

A technology of polyethylene resin and products, applied in the field of polyethylene resin for hollow products and its composition and preparation, can solve the problems such as the reduction of polymer crystallinity and tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

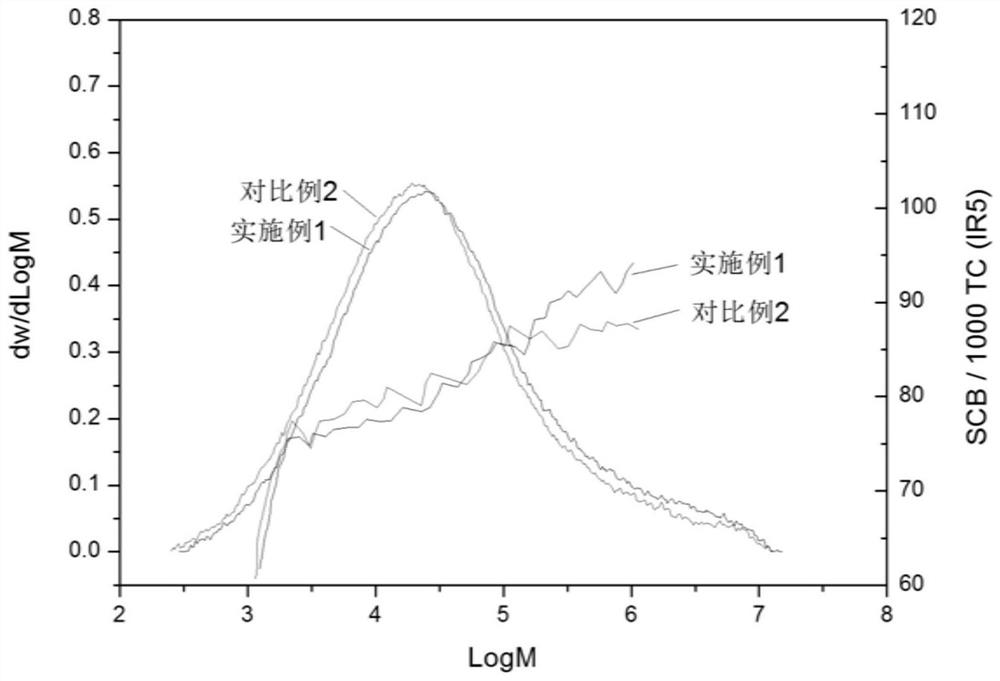

Image

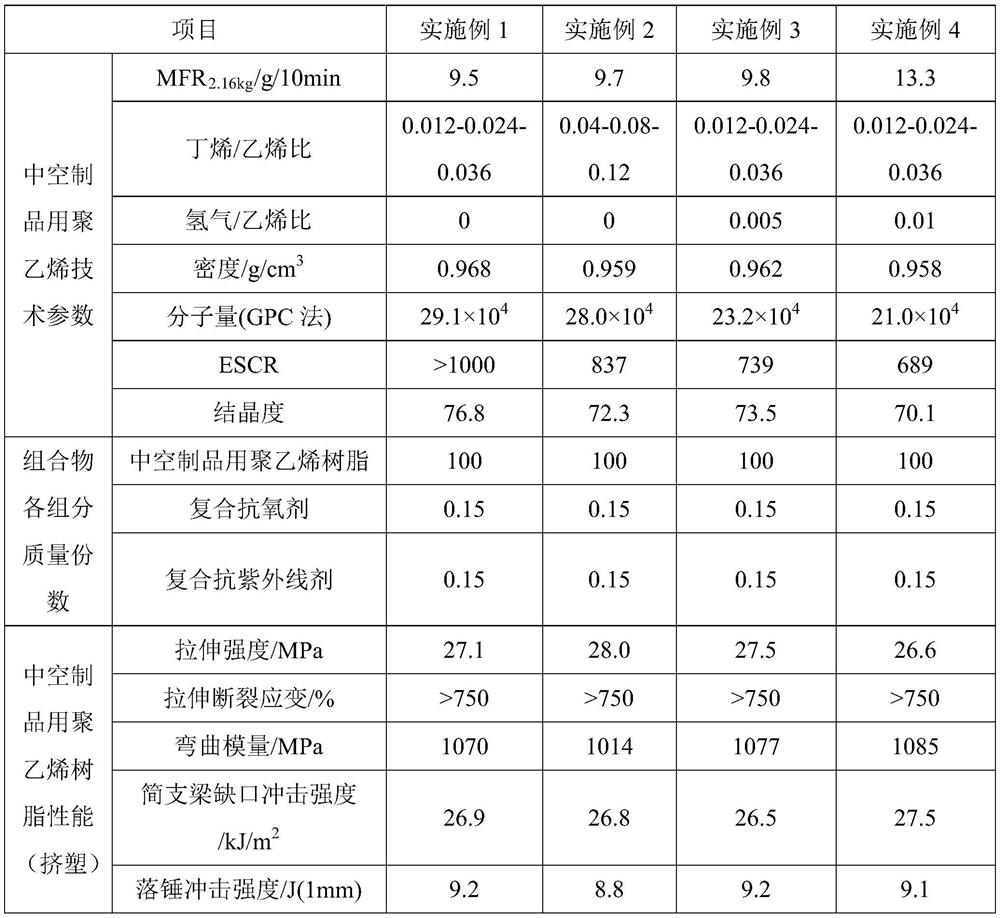

Examples

Embodiment 1

[0057] The first step: preparation of chromium-containing catalyst:

[0058] Weigh 40 grams of 955 silica gel in a 1000ml dry beaker and transfer it to a double-cone drum dryer, start the machine to keep the silica gel in a rolling state. Weigh the chromium acetate solution in a 100ml dry beaker (the loading capacity is 0.6% by mass of chromium), add 60ml of deionized water to make an impregnation solution, and spray the impregnation solution into the mixer at a uniform speed to make the silica gel and the chromium acetate solution fully contact ,well mixed. The temperature of the mixer was raised to 80° C., and drying was carried out for 8 hours at a vacuum degree of -0.1 MPa. Move the dried silica gel carrier into a quartz tube, and pass high-purity nitrogen gas into the bottom. The activation time in the nitrogen state is that the activation gas is switched from high-purity nitrogen to dry air when the temperature rises to 300 ° C, and the activation is maintained at 600 °...

Embodiment 2

[0068] The preparation method of the chromium-containing catalyst is the same as in Example 1.

[0069] The difference between the preparation method of polyethylene resin for hollow products and that of Example 1 is that the comonomer gradient (butene / ethylene molar ratio) used during polymerization is 0.04-0.08-0.12, respectively.

[0070] The preparation method of the polyethylene composition for hollow products is the same as that of Example 1.

Embodiment 3

[0072] The preparation method of the chromium-containing catalyst is the same as in Example 1.

[0073] The difference between the preparation method of polyethylene resin for hollow products and Example 1 is that hydrogen is added during polymerization, and the monomer ratio is hydrogen / ethylene molar ratio 0.005:1.

[0074] The preparation method of the polyethylene composition for hollow products is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com