Modified PGA material with relatively long shelf life and preparation method thereof

A shelf life and modification technology, which is applied in the field of modified PGA materials and its preparation, can solve the problems of affecting product quality, high density of ester groups, and difficulty in controlling the degradation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The raw materials for the preparation of the modified PGA material provided by the present invention include 0.2 to 0.5 parts of a chain extender; the chain extender is a mixture of an epoxy chain extender and dibenzoylhydrazide sebacic acid; The mass ratio of chain agent to dibenzoylhydrazide sebacic acid is preferably 1:0.95-1.05, more preferably 1:1. In a specific embodiment, the amount of the chain extender is 0.3 part or 0.5 part. The epoxy equivalent of the epoxy chain extender is Epoxy equivalent weight = 285g / mol, molecular weight = 6800g / mol; or Epoxy equivalent weight = 185 g / mol, molecular weight = 3800 g / mol. Sebacic acid dibenzohydrazide is added as an additive to promote material crystallization, which can work together with ADR to improve the shelf life and mechanical properties of PGA.

[0025] The raw materials for preparing the modified PGA material provided by the present invention include 70-80 parts of polyglycolic acid; in a specific embodiment...

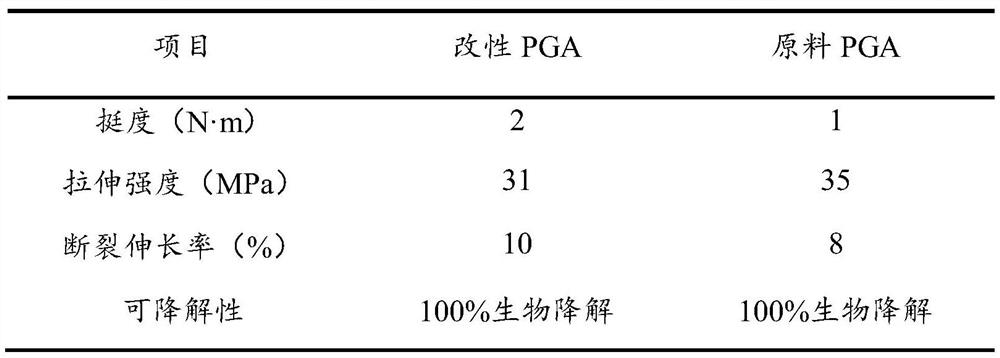

Embodiment 1

[0044] Composition according to the weight ratio of raw materials: 0.3 parts of chain extender, 70 parts of polyglycolic acid (PGA), 25 parts of filler, 4.7 parts of antiblocking agent; the chain extender is epoxy chain extender and decane The mixture of diacid dibenzohydrazide: wherein, the epoxy chain extender is 4370s, epoxy equivalent=185g / mol, molecular weight=3800g / mol, BASF company.

[0045] The filler is edible starch; the opening agent has a specific surface area of 180m 2 / g of nano silicon dioxide, pH value is 4, water content is 1.5%; the molecular weight of the polyglycolic acid is 200,000 g / mol, the melting point is 220°C, and the specific gravity is 1.2g / cm 3 ;

[0046] The twin-screw extrusion process is adopted, and the raw materials are first mixed with a high-speed mixer for 5 minutes, and then put into the twin-screw for granulation. The aspect ratio of the twin-screw extruder is 1:35, while the temperature of the feeding section is kept at 170°C, the...

Embodiment 2

[0052] Composition according to the weight ratio of raw materials: 0.5 parts of chain extender, 80 parts of polyglycolic acid (PGA), 15 parts of filler, 5 parts of antiblocking agent; the chain extender is epoxy chain extender and decane The mixture of diacid dibenzohydrazide: wherein, the epoxy chain extender is Epoxy equivalent=285g / mol, molecular weight=6800g / mol, BASF company.

[0053] The filler is organic montmorillonite; the anti-blocking agent has a specific surface area of 150m 2 / g of nano-silica, the pH value is 4.2, and the water content is 1.5%; the molecular weight of the polyglycolic acid is 200,000 g / mol, the melting point is 220 ° C, and the specific gravity is 1.2 g / cm 3 ;

[0054] The twin-screw extrusion process is adopted, and the raw materials are first mixed with a high-speed mixer for 5 minutes, and then put into the twin-screw for granulation. The aspect ratio of the twin-screw extruder is 1:35, while the temperature of the feeding section is kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com