A kind of high-performance alkali-resistant red reactive dye and preparation method thereof

A reactive dye and red technology, applied in reactive dyes, dyeing methods, organic dyes, etc., can solve the problems of inconsistency in directness, exhaustion rate and reactivity, etc., and achieve the effect of increased alkali resistance and high alkali hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

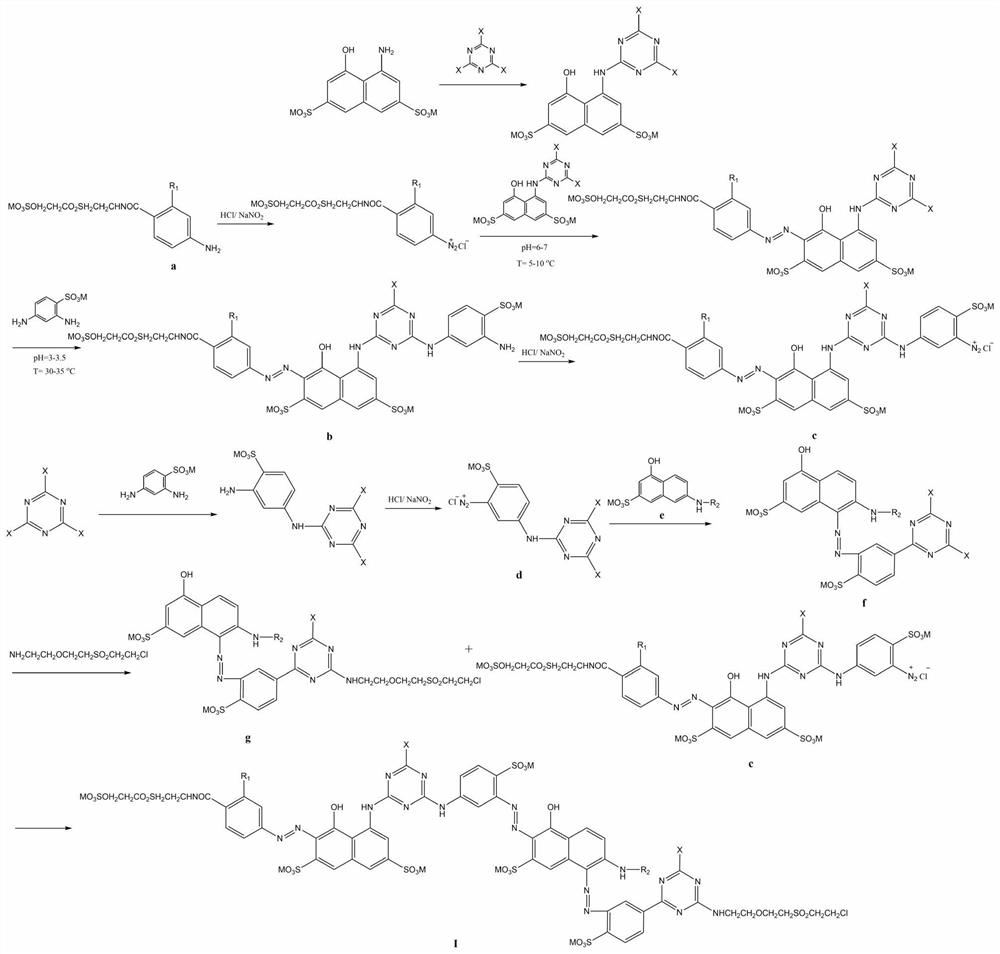

Method used

Image

Examples

Embodiment 1

[0053]

[0054] In this embodiment, commercial reactive red dyes include reactive red dyes 1-2, diffusants (methylnaphthalenesulfonic acid formaldehyde condensates, the degree of condensation is 4, and the degree of sulfonation is 2), and the mass percentage is 85%. Reactive red dye, 5% by mass percentage of diffusing agent, 0.1% by mass percentage of water-based polymer dustproof agent, and 9.9% by mass percent of sodium sulfate.

[0055] Take 2g of the above-mentioned commercial dye, add 8g of urea, 2.5g of baking soda, 60g of sodium alginate paste, 1g of resist salt and 26.5g of water to prepare a reactive red printing paste, print the cotton fabric, and dry it at 85°C. Then steam at 100° C. for 7 minutes (relative humidity 70%), wash and dry to obtain dyed fabrics, and the product performance test results are shown in Table 1.

[0056] The preparation method of described reactive red dye I-1 comprises the steps:

[0057] Step 1: Add 35.2g of 4-amino-(2'-((2"-(sulfate)e...

Embodiment 2

[0066]

[0067] In this embodiment, commercial reactive red dyes include reactive red dyes 1-2, diffusants (methylnaphthalenesulfonic acid formaldehyde condensates, the degree of condensation is 4, and the degree of sulfonation is 2), and the mass percentage is 85%. Reactive red dye, mass percent is 5% diffusing agent, mass percent is 0.1% water-based polymer dustproof agent, mass percent is 9.9% sodium sulfate;

[0068] Take 2g of the above-mentioned commercial dye, add 8g of urea, 2.5g of baking soda, 60g of sodium alginate paste, 1g of resist salt and 26.5g of water to prepare a reactive red printing paste, print the cotton fabric, and dry it at 85°C. Then steam at 100° C. for 7 minutes (relative humidity 70%), wash and dry to obtain dyed fabrics, and the product performance test results are shown in Table 1.

[0069] In this example, the preparation method of the reactive dye I-2 is the same as in Example 1, except that N-methyl J acid replaces the J acid in the prepara...

Embodiment 3

[0071] The difference between this embodiment and embodiment 1 is:

[0072] In this embodiment, the commercial dyeing agent includes 75% by mass of reactive red dye, 5% by mass of diffusing agent, 0.1% by mass of dustproof agent, and 5% by mass of sodium sulfate.

[0073] In this example, the molar ratio of compound a to sodium nitrite is 1:1.01 to 1.03; the molar ratio of compound a to hydrochloric acid is 1:1.05 to 1.1; the molar ratio of cyanuric chloride or cyanuric fluoride to H acid The ratio is 1:1~1.03:1;

[0074] In this example, the molar ratio of 2,4-diaminobenzenesulfonic acid to H acid monoazo red reactive dye is 0.98:1 to 1:1; the molar ratio of 2,4-diaminobenzenesulfonic acid to hydrochloric acid 1:2.5~1:2.8; the molar ratio of 2,4-diaminobenzenesulfonic acid to sodium nitrite is 1:1.01~1:1.03;

[0075] In this embodiment, the molar ratio of 2,4-diaminobenzenesulfonic acid to sodium nitrite is 1:1.01~1.03; the molar ratio of 2,4-diaminobenzenesulfonic acid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com