Method for detecting polymerization degree of sodium alginate oligosaccharide

A technology of sodium alginate and oligosaccharide, applied in the field of carbohydrate analysis, can solve the problems of complicated operation, large error, high detection cost, etc., and achieve the effect of simplifying the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

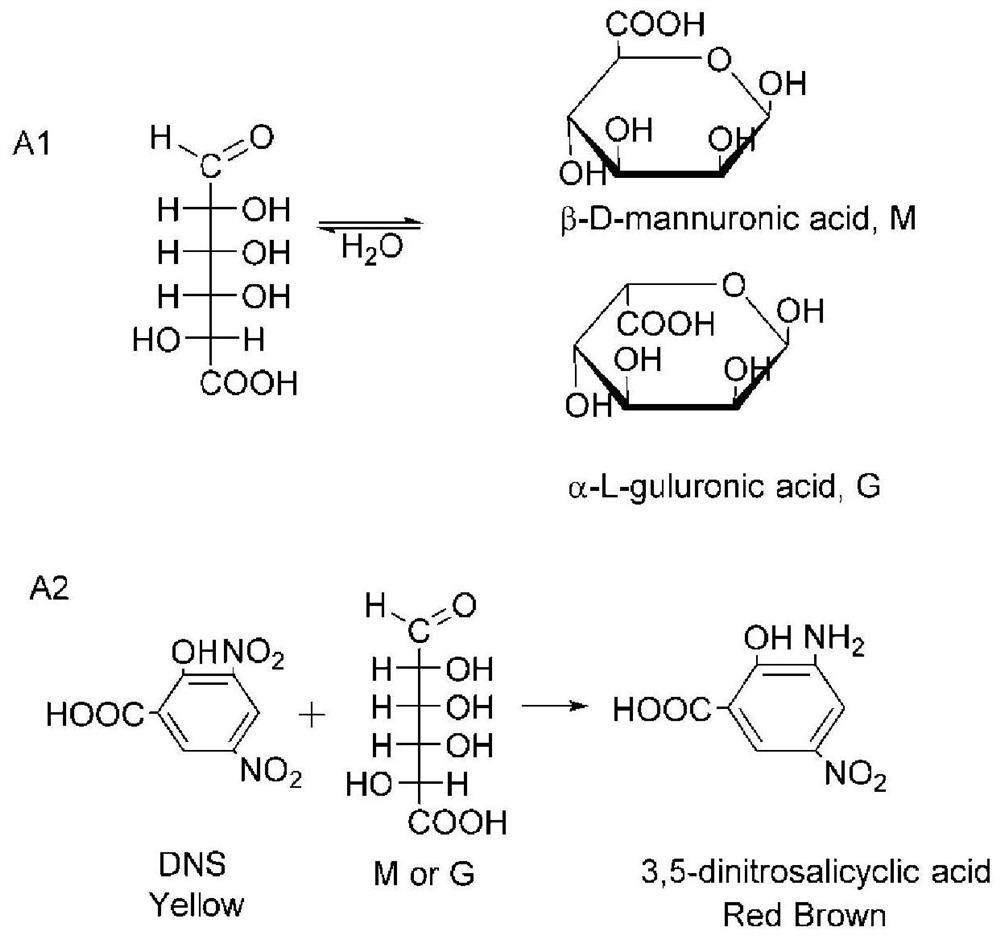

Method used

Image

Examples

Embodiment 1

[0031] (1) Prepare DNS (3,5-dinitrosalicylic acid) reagent: add 45.5g potassium sodium tartrate to 125ml hot water to dissolve, add 1.575g DNS and 65.5ml 2mol / L NaOH; then add 1.25g Distill phenol and 1.25g of sodium sulfite, stir to dissolve, after cooling, dilute to 250ml with distilled water and store in a brown bottle, set aside for 7 days before use;

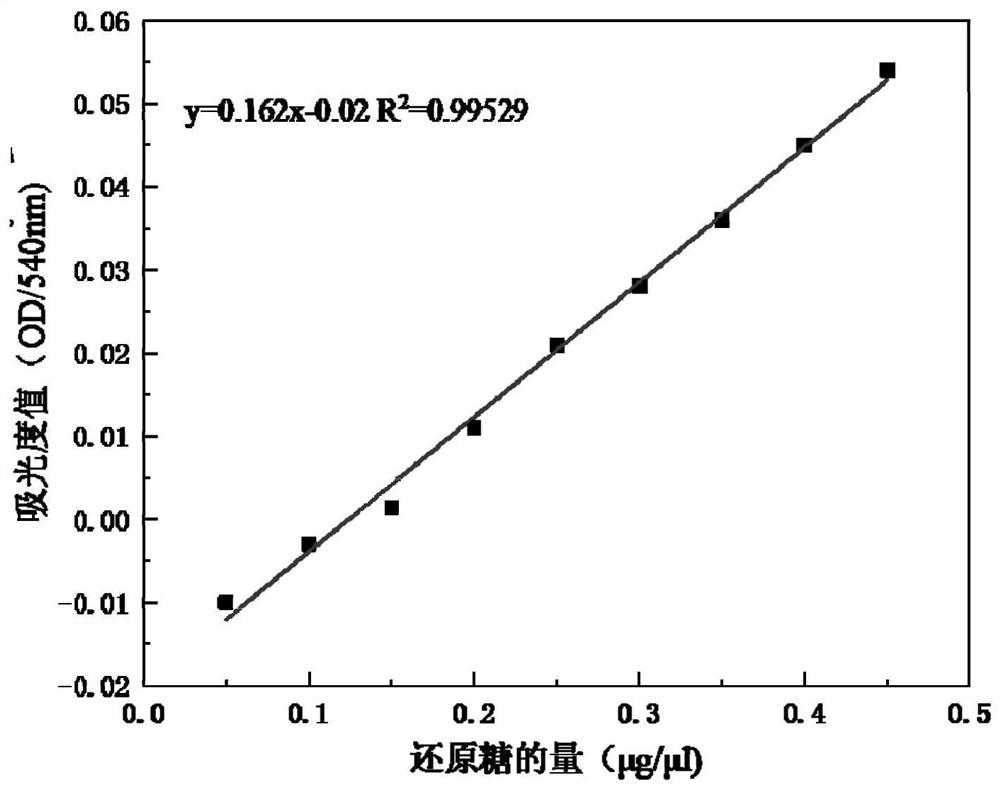

[0032] (2) drawing of standard curve: configure the glucose solution of different concentrations, adopt DNS method to measure its absorbance value at 540nm, obtain different glucose concentration and absorbance curve figure, as standard curve figure; Figure 4 Shown: the standard curve is y=0.16x-0.02

[0033] (3) Configuration of a series of oligosaccharide solutions: take oligomeric sodium alginate, both of which are mixed fragments of mannuronic acid and guluronic acid, and prepare a solution with a concentration of 1 mg / ml;

[0034] (4) Pipette 128 μl of the solution into the test tube, add 96 μl of DNS reagent to deve...

Embodiment 2

[0038] Other steps of the present invention are with embodiment 1

[0039] (3) Take oligomeric sodium alginate, all of which are guluronic acid fragments, and configure it into a solution with a concentration of 1 mg / ml;

[0040] (4) Pipette 128 μl of the solution into the test tube, add 96 μl of DNS reagent to develop color at 100°C for 10 minutes, take it out to room temperature 25°C, add 1.376ml of water once, then draw 200 μl of the solution into a cuvette, and measure the reduction of 540nm Sugar absorbance value. The percent content of reducing sugar calculated by standard curve is 10.96%,

[0041] (5) Substituting into the equation y=1.085x-0.136, the corresponding average degree of polymerization is 9.67; the average degree of polymerization detected by NMR is 9.8.

Embodiment 3

[0043] Other steps of the present invention are with embodiment 1

[0044] (3) Take oligomeric sodium alginate, which is a mixed fragment of mannuronic acid and guluronic acid, and configure it into a solution with a concentration of 1 mg / ml;

[0045] (4) Pipette 128 μl of the solution into the test tube, add 96 μl of DNS reagent to develop color at 100°C for 10 minutes, take it out to room temperature 25°C, add 1.376ml of water once, then draw 200 μl of the solution into a cuvette, and measure the reduction of 540nm Sugar absorbance value. The percent content of reducing sugar calculated by standard curve is 29.57%,

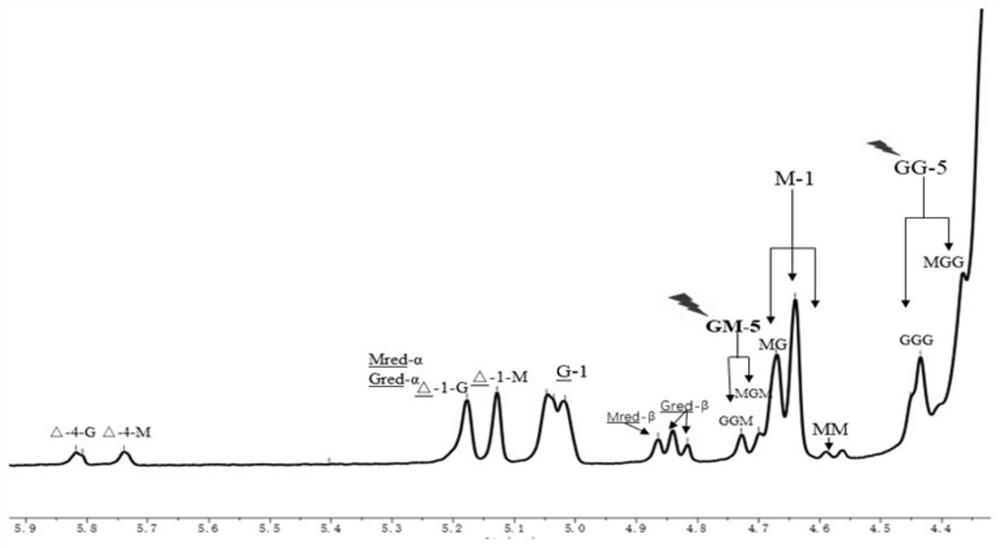

[0046] (5) Substituting into the equation y=1.085x-0.136, the corresponding average degree of polymerization is 3.61; the average degree of polymerization detected by NMR is 3.6. Detection by ESI-MS again, as Figure 5 , it can be seen that the oligosaccharide mixture contains disaccharides, trisaccharides, and tetrasaccharides, and the content of disaccharid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com