Nondestructive testing system and method for turbine disc by using bilinear array transducer

A transducer and bilinear technology, applied in the direction of processing detection response signals, etc., can solve the problems of low imaging resolution, low detection resolution, and affecting the performance of aeroengines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

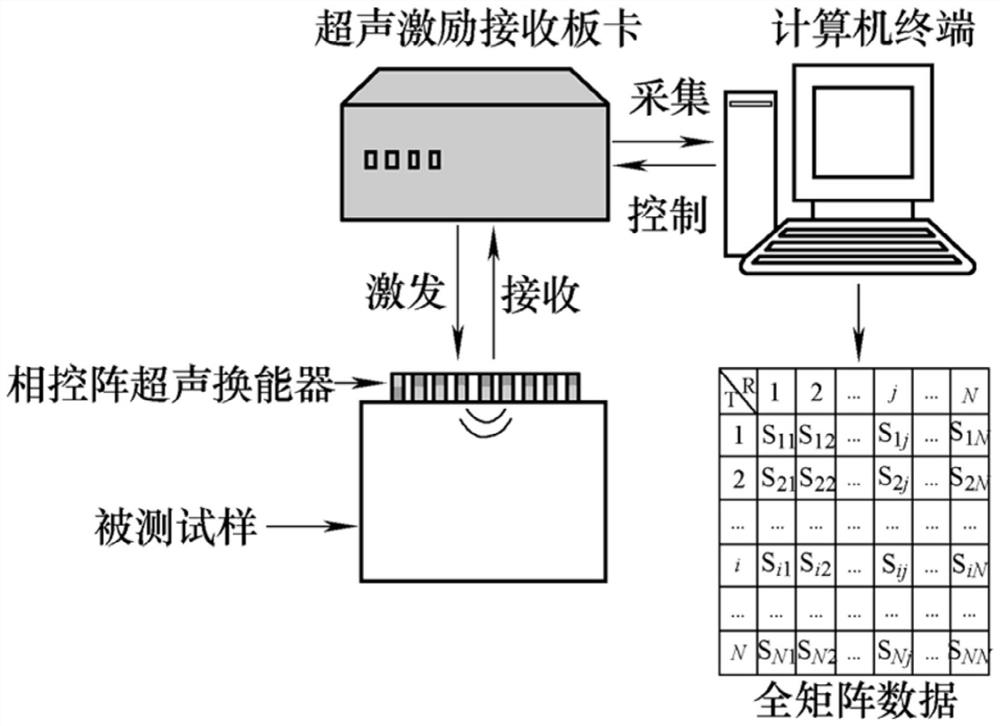

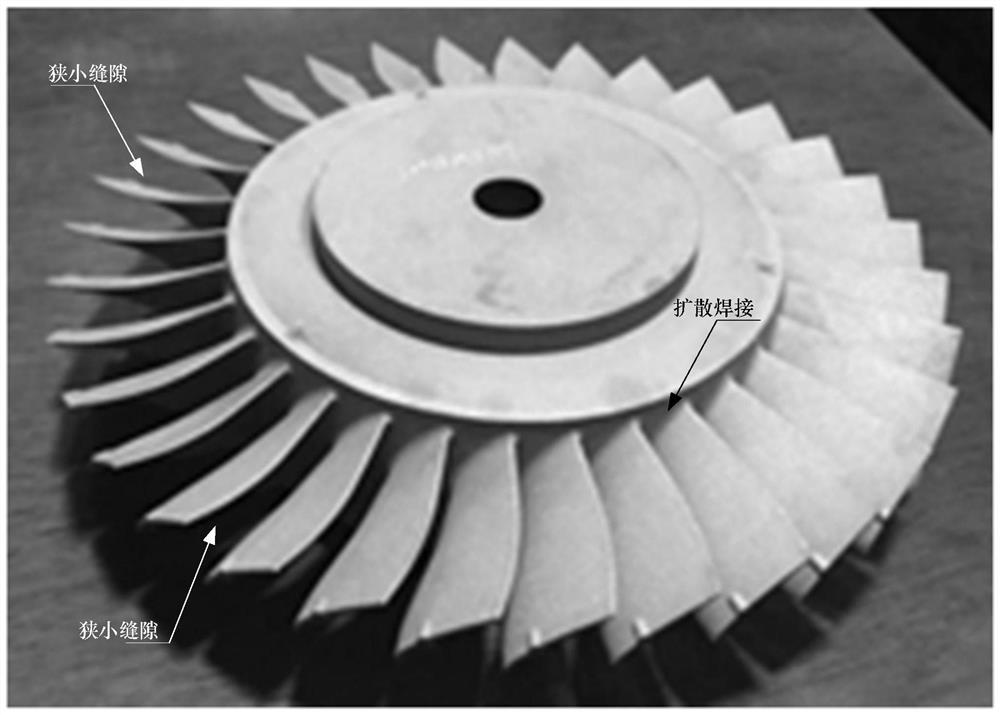

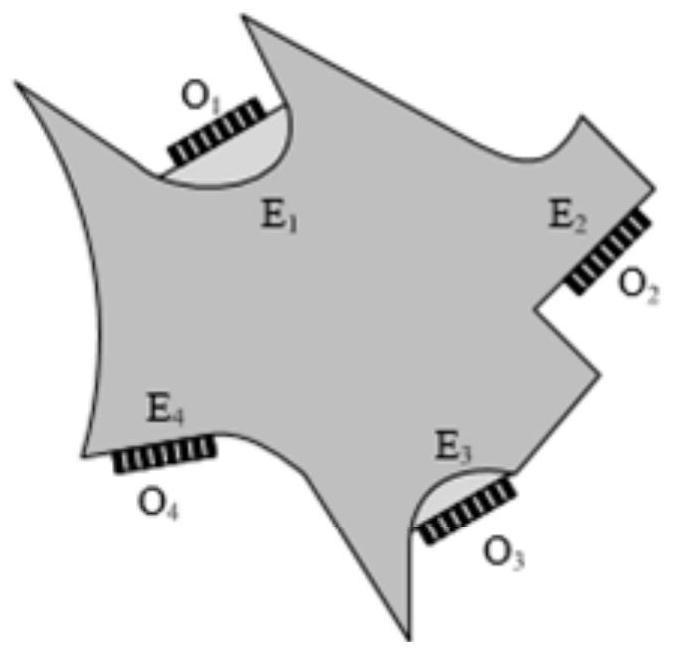

[0053] In the present invention, the dual linear array transducer includes an array ultrasonic pocket board and an ultrasonic probe. Due to the large number of blades of the aviation superalloy disc (such as figure 2 As shown), one or more ultrasonic probes need to be arranged on each blade, and the number of interfaces of each array ultrasonic pocket board is fixed, so a branch line is connected between the array ultrasonic pocket board and the ultrasonic probe The array ultrasonic pocket board and the computer are connected with an ultrasonic excitation receiving board, such as image 3 shown. Ultrasound probes are one-dimensional linear probes with multiple element elements. see figure 2 As shown, if a pair of probes are arranged at the diffusion welding of the blade (that is, the transmitter probe is placed above the blade, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com