Low-density surfacing flux with long-fiber wollastonite as frame and preparation method thereof

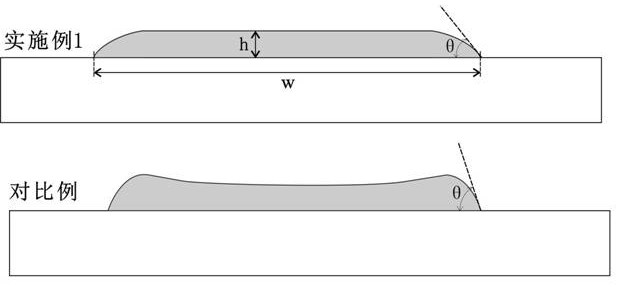

A wollastonite and long fiber technology is applied in the field of low-density surfacing flux and its preparation, which can solve the problems of affecting flux permeability and arc stability, flux particles easily collided and fragmented, and gas indentation on the surface of the weld bead, etc. Achieve the effect of avoiding gas indentation on the surface of the weld bead, good wear resistance, and delaying the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the low-density surfacing welding flux with long fiber wollastonite as the frame comprises the following steps:

[0036] S1: Mix the above-mentioned raw materials uniformly in proportion, then add pure potassium water glass and stir evenly, the weight of pure potassium water glass is 20-25% of the total weight of raw materials, and the mixed raw materials are obtained;

[0037] S2: The prepared mixed raw materials are rolled and granulated by rotating the swash plate, followed by low-temperature drying at 120-160°C, sieving, and crushing of flux particles. The sieving particle size is 8-40 mesh, and then high-temperature drying at 650-720 Dry, that is, the finished flux is produced.

Embodiment 1

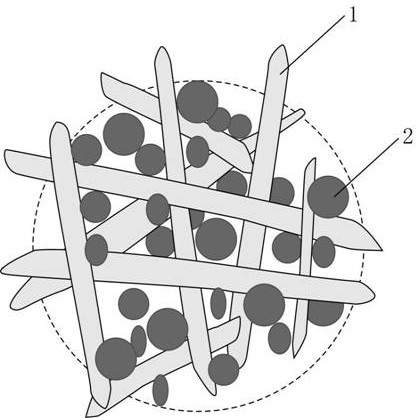

[0039] This embodiment provides a low-density surfacing flux with long-fiber wollastonite as the frame, including the following raw materials in mass percentages: 41% long-fiber wollastonite, 25% alumina, 13% fluorite, and 15% potassium feldspar , Cr powder 3%, Mn powder 1.5% and SiFe1.5%.

[0040] Wherein, the prepared long-fiber wollastonite is in the shape of a slender rod with a length of 500 μm and an aspect ratio ≥ 10:1.

[0041] This embodiment also provides a method for preparing low-density surfacing flux with long-fiber wollastonite as a frame, comprising the following steps:

[0042] S1: Mix the above-mentioned raw materials in proportion, then add pure potassium water glass and stir evenly, the weight of pure potassium water glass is 22% of the total weight of raw materials, and the mixed raw materials are obtained;

[0043] S2: The prepared mixed raw materials are rolled and granulated by rotating the swash plate, followed by low-temperature drying at 120°C, siev...

Embodiment 2

[0045] This embodiment provides a low-density surfacing flux with long-fiber wollastonite as the frame, including the following raw materials in mass percentages: 45% long-fiber wollastonite, 25% alumina, 13% fluorite, and 12% potassium feldspar , Cr powder 3%, Mn powder 1% and SiFe 1%.

[0046] Wherein, the prepared long-fiber wollastonite is in the shape of a slender rod with a length of 1000 μm and an aspect ratio ≥ 10:1.

[0047] This embodiment also provides a method for preparing low-density surfacing flux with long-fiber wollastonite as a frame, comprising the following steps:

[0048] S1: Mix the above-mentioned raw materials in proportion, then add pure potassium water glass and stir evenly, the weight of pure potassium water glass is 20% of the total weight of the raw materials, and the mixed raw materials are obtained;

[0049] S2: The prepared mixed raw materials are rolled and granulated by rotating the swash plate, followed by low-temperature drying at 140°C, si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com