Prussian blue analogue and preparation method, negative electrode material and application thereof

A technology of Prussian blue and negative electrode materials, applied in the field of Prussian blue analogs and their preparation, can solve the problems of poor cycle stability and low discharge capacity of lithium ion negative electrode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] 1, a kind of Prussian blue analog negative electrode material provided by the present invention, comprises Prussian blue analog, is applied to lithium ion battery, and the chemical formula of Prussian blue analog is K x Mn[R(CN) 6 ] 1-y □ y .nH 2 O, where 0≤x≤2, 0.36 ] Vacancy. The preparation method of Prussian blue analogue comprises the steps:

[0055] (1) Get K 3 R(CN) 6 The aqueous solution (or ethanol / water mixed solution), denoted as solution A;

[0056] (2) Obtain a mixed aqueous solution (or ethanol / water mixed solution) of a transition metal salt of Mn and tripotassium citrate (or polyvinylpyrrolidone, PVP, K-30), denoted as solution B;

[0057] (3) Add the solution A dropwise to the solution B, continue to heat and stir after the dropwise addition, and precipitate for several hours, separate the solid from the liquid, collect and wash the precipitate, and dry to obtain the negative electrode of the Prussian blue analog Material.

[0058] In some embo...

Embodiment 1

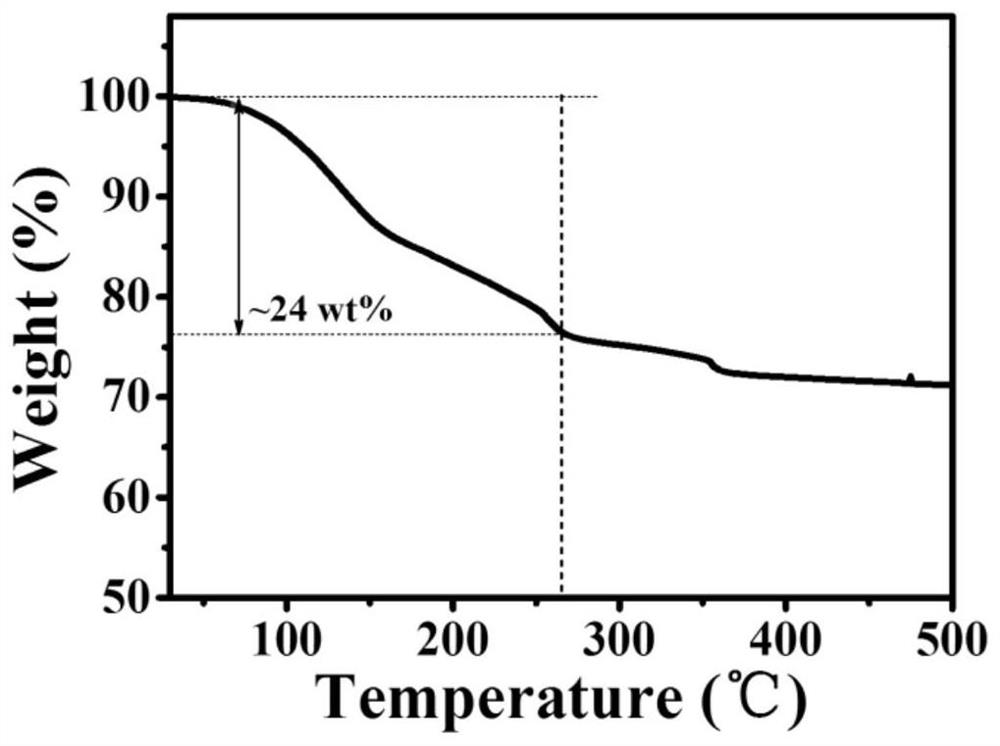

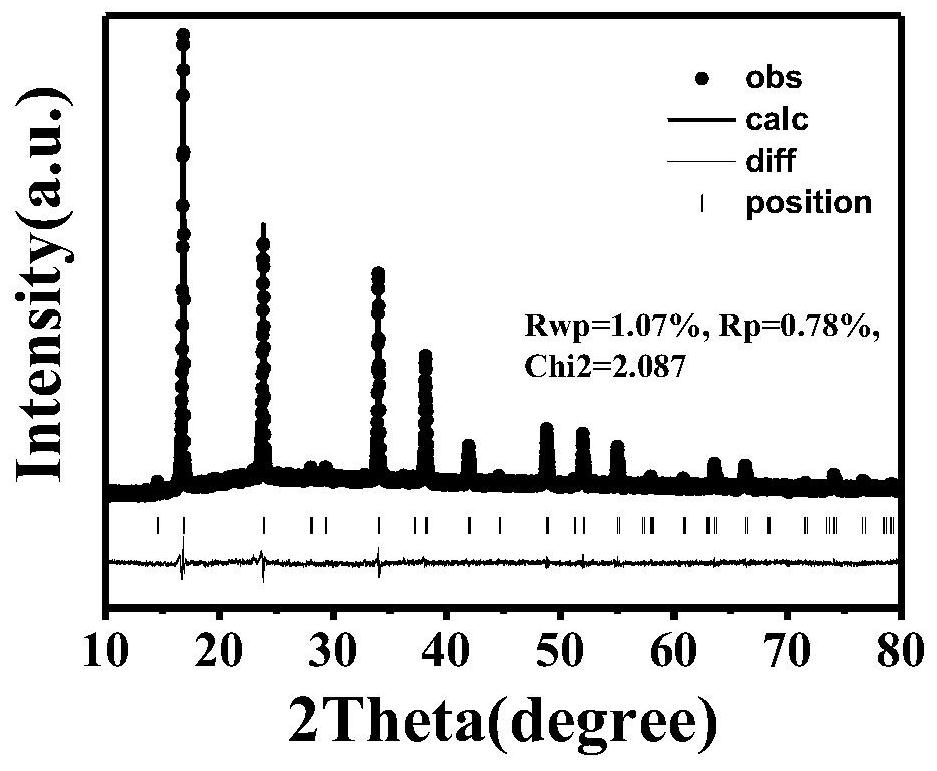

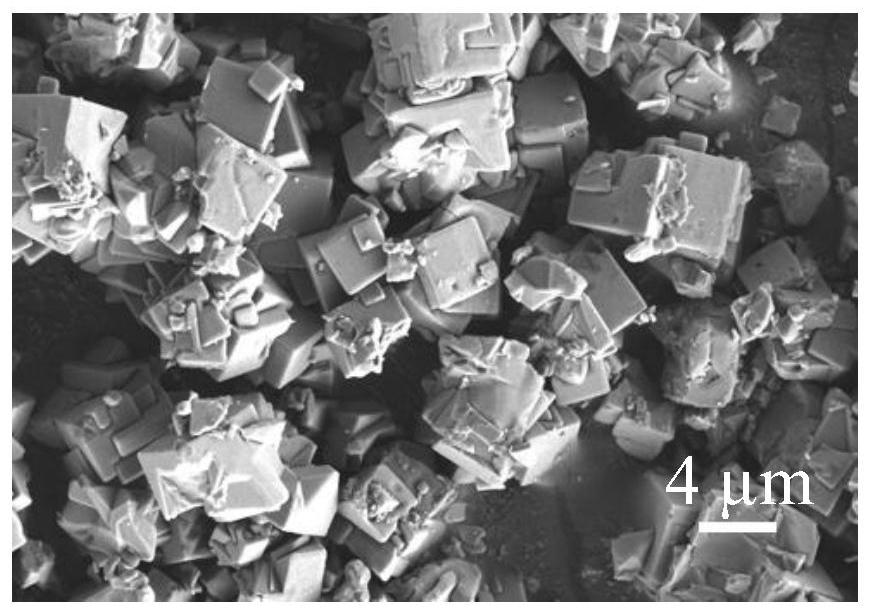

[0069] A Prussian blue analog negative electrode material, the chemical formula of the negative electrode material is expressed as K 0.09 Mn[Fe(CN) 6 ] 0.66 □ 0.34 3.40H 2 O, □ is [Fe(CN) 6 ] vacancies; the crystalline H of the material 2 The O content is ~24wt%, and the Mn-N bond length is 2.21445A°. The preparation method of this negative electrode material comprises the steps:

[0070] 1) Weigh 4mmol of K 3 Fe(CN) 6 , dispersed in 200mL deionized water, stirred to form a uniform solution A;

[0071] 2) Weigh 6mmol of MnSO 4 Disperse in 200mL deionized water and stir to form a uniform solution B;

[0072] 3) Use a peristaltic pump to add solution A to solution B at a rate of 5mL / min, heat and stir at 25°C for 12 hours, and after sedimentation for 12 hours, separate the precipitate from the product through a high-speed centrifuge, and use deionized water and Wash with ethanol for 3 times, and then vacuum-dry for 24 hours at a pressure of 20kPa and a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com