Extraction, separation and purification method of aconitum alkaloid

A technology for separation and purification of alkaloids, applied in the direction of organic chemistry, etc., can solve the problems of easy degradation in the extraction process, large consumption of organic solvents, and low purity of products, and achieve the effect of accelerating separation speed, improving extraction rate, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Extraction: crush the medicinal material containing aconitum alkaloids, and pass through a 100-mesh sieve to obtain medicinal material powder. Take 1.0kg of medicinal material powder, add 2L of acidified ethanol solution, and use ultrasonic power density of 200W / cm at 25°C 2 And ultrasonic frequency 100kHz, ultrasonic extraction for 30min, filter, filter out insoluble matter, use 25mL petroleum ether to degrease and repeat twice, use ammonia water to alkalinize to pH = 9, and distill the solvent under reduced pressure at 40°C to obtain crude alkaloid.

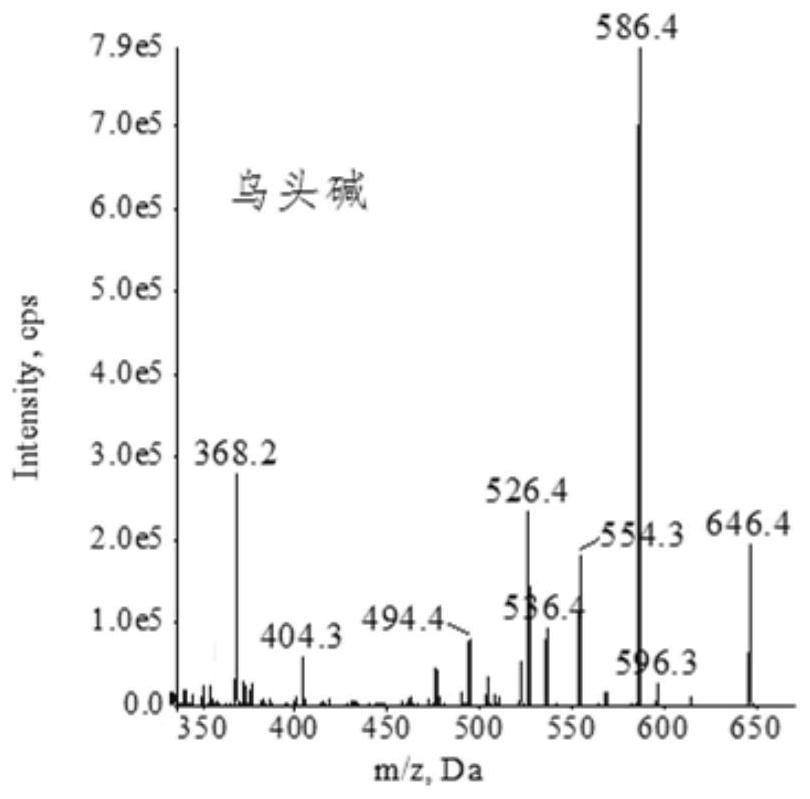

[0041] (2) Separation: Weigh 0.50 g of the crude alkaloid obtained above, select a mixed solvent containing ions doped as the HSCCC solvent system, add 200 mL of the HSCCC solvent system and the crude alkaloid into the separatory funnel, oscillate to fully mix the solution , placed overnight, and separated into upper and lower phases after equilibration. With the upper phase of the solvent system as the stationary p...

Embodiment 2

[0047] (1) Extraction: crush the medicinal material containing aconitum alkaloids, and pass through a 100-mesh sieve to obtain medicinal material powder. Take 1.0kg of medicinal material powder, add 1L of acidified ethanol solution, extraction temperature is 20°C, ultrasonic power density is 150W / cm 2 At an ultrasonic frequency of 10 kHz, ultrasonically extract for 30 min, filter to remove insoluble matter, degrease with 25 mL of petroleum ether and repeat twice, alkalinize with ammonia water to pH=9, and distill off the solvent under reduced pressure at 40°C to obtain a crude alkaloid.

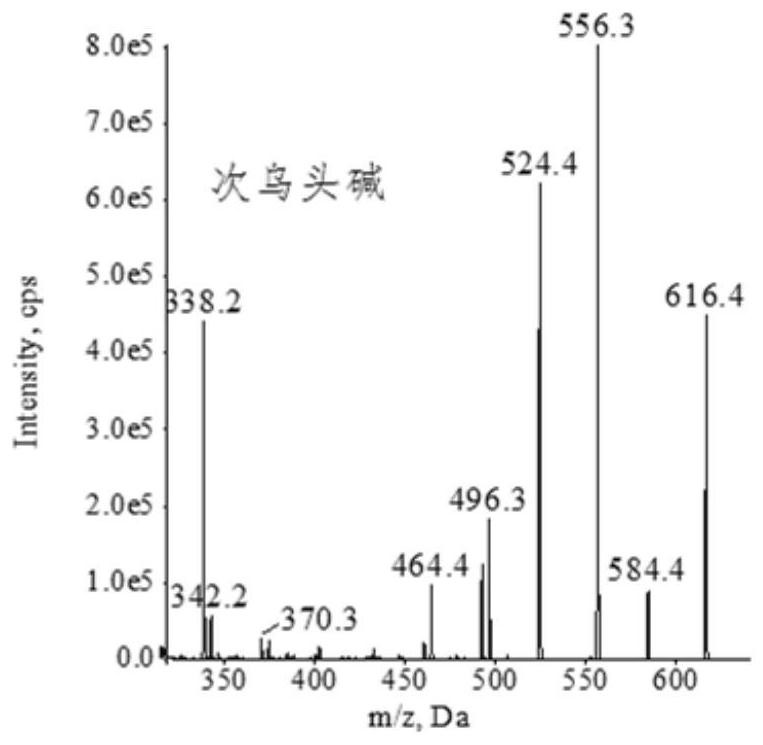

[0048] (2) Separation: Weigh 0.50 g of the crude alkaloid obtained above, select a mixed solvent containing ions as the HSCCC solvent system, add 100 mL of the HSCCC solvent system and the crude alkaloid into the separatory funnel, and oscillate to fully mix the solution , placed overnight, and separated into upper and lower phases after equilibration. With the upper phase of the solvent sys...

Embodiment 3

[0053] (1) Extraction: crush the medicinal material containing aconitum alkaloids, and pass through a 100-mesh sieve to obtain medicinal material powder. Take 1.0kg of medicinal material powder, add 5L of acidified ethanol solution, extraction temperature is 30°C, ultrasonic power density is 10W / cm 2 And ultrasonic frequency 80kHz, ultrasonic extraction for 30min, filter to remove insoluble matter, degrease with 25mL petroleum ether and repeat twice, alkalinize with ammonia water to pH=9, distill off the solvent under reduced pressure at 40°C to obtain crude alkaloid.

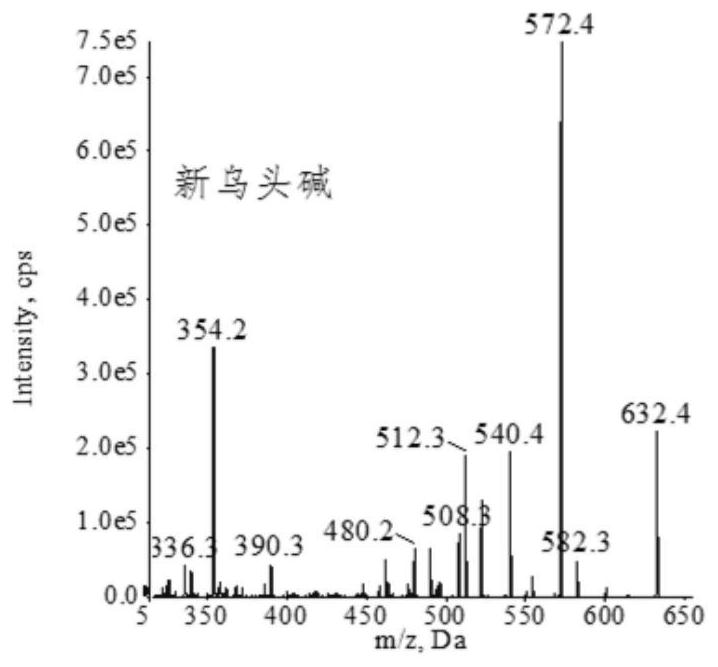

[0054] (2) Separation: Weigh 0.50 g of the crude alkaloid obtained above, select a mixed solvent containing ions doped as the HSCCC solvent system, add 500 mL of the HSCCC solvent system and the crude alkaloid into the separatory funnel, oscillate to fully mix the solution , placed overnight, and separated into upper and lower phases after equilibration. With the upper phase of the solvent system as the statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com