Aniline compound-containing surfactant composition for oil displacement, preparation method and application thereof

A technology of surfactant and composition, applied in the field of surfactant composition for oil displacement, can solve the problems of low interface efficiency, poor solubilization ability of crude oil, large adsorption retention, etc., achieve good technical effect and improve crude oil recovery. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

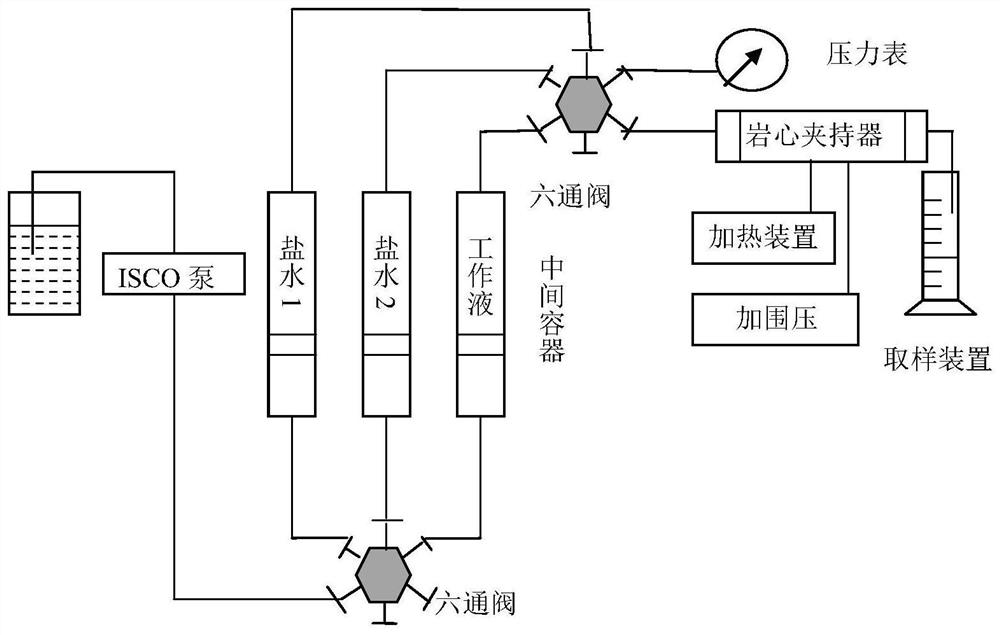

Method used

Image

Examples

Embodiment 1

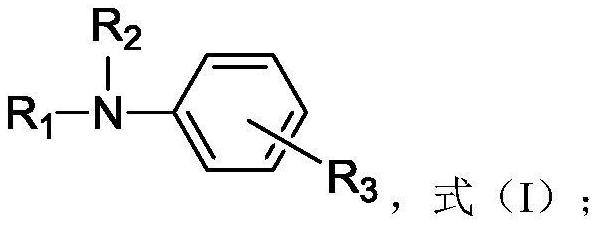

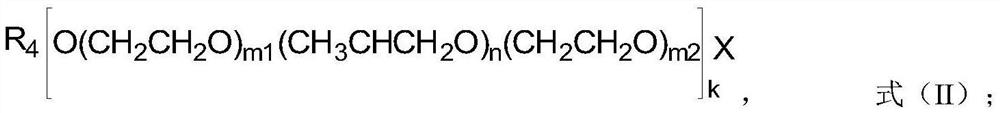

[0098] Surfactant shown in formula (II):

[0099] RO(CHCH 3 CH 2 O) 12 (CH 2 CH 2 O) 2 CH 2 COONa

[0100] where R=iso-C 13 h 27 .

[0101] (1) Add 200 grams (1 mole) of isotridecanol, 4 grams of potassium hydroxide and 2.6 grams of anhydrous potassium carbonate to a pressure reactor equipped with a stirring device, and when heated to a reaction temperature of 80-90 ° C, open Vacuum system, dehydrate under high vacuum for 1 hour, then replace with nitrogen for 3 to 4 times, adjust the reaction temperature of the system to 150°C and slowly feed 701.8 grams (12.1 moles) of propylene oxide, control the pressure ≤ 0.50MPa, and wait for the ring to After the reaction of propylene oxide, the temperature was lowered, and 88.0 g (2.0 moles) of ethylene oxide was slowly introduced at 130° C., and the pressure was controlled to be ≤0.60 MPa. After the reaction, the temperature was lowered to 90° C., low boilers were removed in vacuum, neutralized and dehydrated after cooling ...

Embodiment 2

[0104] Surfactant shown in formula (II):

[0105] RO(CH 2 CH 2 O) 2 (CHCH 3 CH 2 O) 12 (CH 2 CH 2 O) 2 CH 2 COOH.N(C 2 h 5 ) 3

[0106] Among them, the carbon chain distribution of R is: C 14 =5.53%, C 16 =62.93%, C 18 = 31.54%.

[0107] (1) Add 248 grams (1 mole) of mixed alcohol (C 14~18 ), 6.5 grams of potassium hydroxide, when heated to 80-90°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, then replace with nitrogen for 3-4 times, adjust the reaction temperature of the system to 140°C and slowly introduce 90.2 gram (2.05 moles) of ethylene oxide, then slowly feed 707.6 grams (12.2 moles) of propylene oxide at 150 °C, control the pressure ≤ 0.60 MPa, and then adjust the temperature to 140 °C slowly after the reaction of propylene oxide Pass 90.2 grams (2.05 moles) of ethylene oxide, and control the pressure to ≤0.40 MPa. After the reaction is over, lower the temperature to 90°C, remove low boilers in a vacuum, neutralize and dehydrat...

Embodiment 3

[0110] Surfactant shown in formula (II):

[0111]

[0112] (1) Add 242 grams (1 mole) of isomeric cetyl alcohol, 8 grams of potassium hydroxide and 5.5 grams of anhydrous potassium carbonate to a 2L pressure reactor equipped with a stirring device, and when heated to 80-90 ° C, turn on the vacuum The system was dehydrated under high vacuum for 1 hour, and then replaced with nitrogen for 3 to 4 times. The reaction temperature of the system was adjusted to 140°C and 178.2 grams (4.05 moles) of ethylene oxide was slowly passed in, and then slowly passed in at 150°C. 350.9 grams (6.05 moles) of propylene oxide, the control pressure is ≤0.60MPa, after the reaction of propylene oxide is completed, adjust the temperature to 140°C and slowly feed 88.0 grams (2.0 moles) of ethylene oxide, the control pressure is ≤0.40MPa . After the reaction was completed, the temperature was lowered to 90°C, low boilers were removed in vacuum, neutralized and dehydrated after cooling to obtain 894...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Carboxylation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com