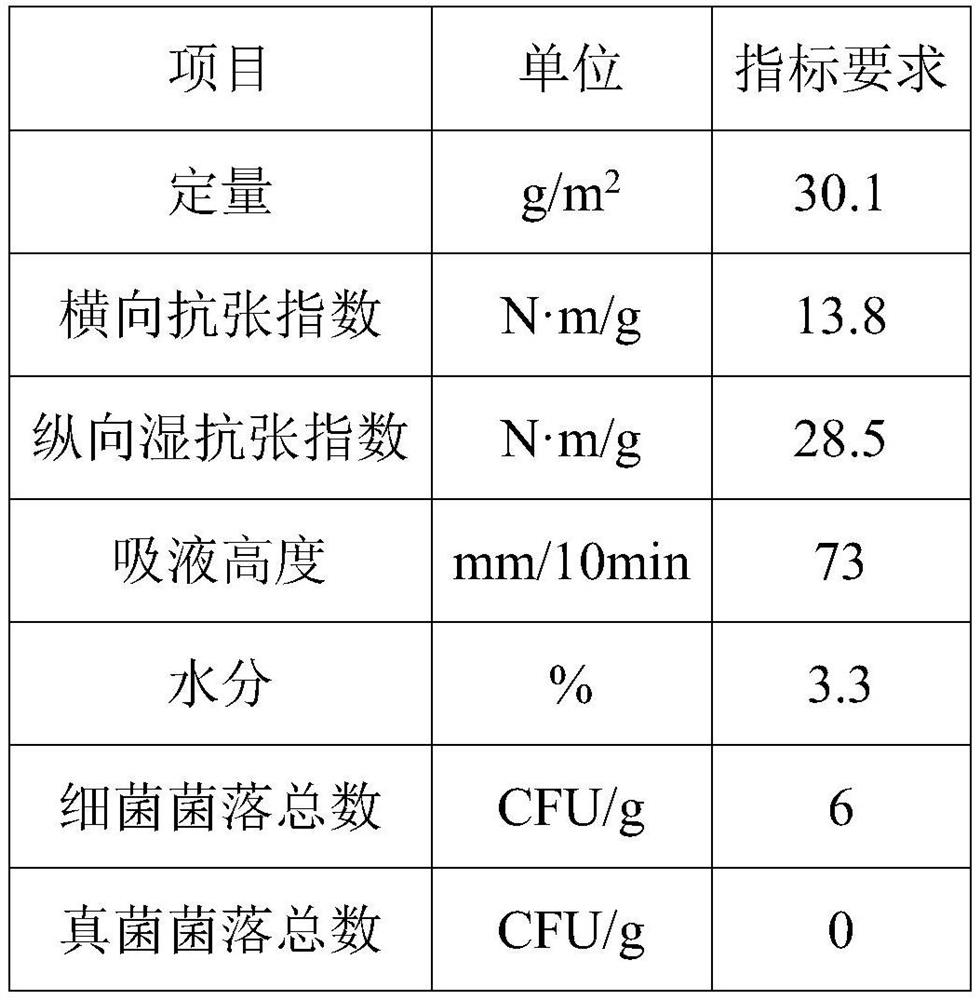

Preparation method of antibacterial food wiping paper

A technology for wiping paper and food, applied in special paper, textiles and papermaking, papermaking, etc., can solve problems such as unsafe hidden dangers, secondary pollution, allergic food, etc., and achieve high suitable strength, low production cost, and high absorbency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of antibacterial food wiping paper, comprises the following steps:

[0035] S1. Using bleached sisal pulp and water-soluble fiber as raw materials, the mass percentages of the two are 98% and 2% respectively; after the bleached sisal pulp is pulped and beaten in turn, water-soluble fiber is added, and the beating concentration is 2.0% , power 100KW, time 35min, beating degree 30°SR; add accelerator CMC-40 during the beating process, the addition amount is 0.2% of the dry pulp amount; add APAM auxiliary agent and defoamer after the treatment, the APAM addition amount is 0.5% of absolute dry pulp, defoaming agent is 2.0kg / ton of paper;

[0036] S2, the mixed pulp is carried out on the rotary wire paper machine or the inclined wire paper machine, wherein the online concentration is 0.03%, the speed is 150m / min, and the formed wet paper sheet with a moisture content of 90% is obtained;

[0037] S3. Press and dehy...

Embodiment 2

[0043] The present embodiment provides a kind of preparation method of antibacterial food wiping paper, comprises the following steps:

[0044]S1. Using bleached softwood pulp, bleached sisal pulp, and water-soluble fiber as raw materials, the mass percentages of the three are 20%, 78%, and 2% respectively; pulping and pulping the bleached softwood pulp and bleached sisal pulp After the beating treatment, water-soluble fiber was added and mixed evenly. During the beating process of bleached softwood pulp and bleached sisal pulp, accelerator CMC-40 was added respectively, and the addition amount was 0.3% and 0.2% of the dry pulp respectively; among them, the bleached softwood pulp Beating concentration 3.5%, power 110KW, time 30min, beating degree 30°SR; bleached sisal pulp beating concentration 2.0%, power 100KW, time 35min, beating degree 28°SR; then add APAM additives and defoaming to the mixed pulp agent, the amount of APAM added is 0.2% of the absolute dry pulp, and the de...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of antibacterial food wiping paper, comprises the following steps:

[0053] S1. Using bleached hemp pulp and water-soluble fiber as raw materials, the mass percentages of the two are 98% and 2% respectively, the bleached hemp pulp is subjected to pulping and beating in turn, and then water-soluble fiber is added, wherein the beating concentration is 2.2% , power 115KW, time 35min, beating degree 28°SR; add accelerator CMC-40 during the beating process, the amount added is 0.4% of the absolute dry pulp amount; 0.4% of absolute dry pulp, defoaming agent is 1kg / ton of paper;

[0054] S2, the mixed pulp is carried out on the rotary wire paper machine or the inclined wire paper machine, wherein the online concentration is 0.02%, the speed is 200m / min, and the formed wet paper sheet with a moisture content of 85% is obtained;

[0055] S3. Press and dehydrate the formed wet paper to obtain a water content of 65%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse tensile index | aaaaa | aaaaa |

| Transverse tensile index | aaaaa | aaaaa |

| Transverse tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com