Cu2-xSe supercapacitor negative electrode material with high specific capacity

A cu2-xse and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems such as unsatisfactory specific capacity, and achieve the effects of improving stability, fast kinetics, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

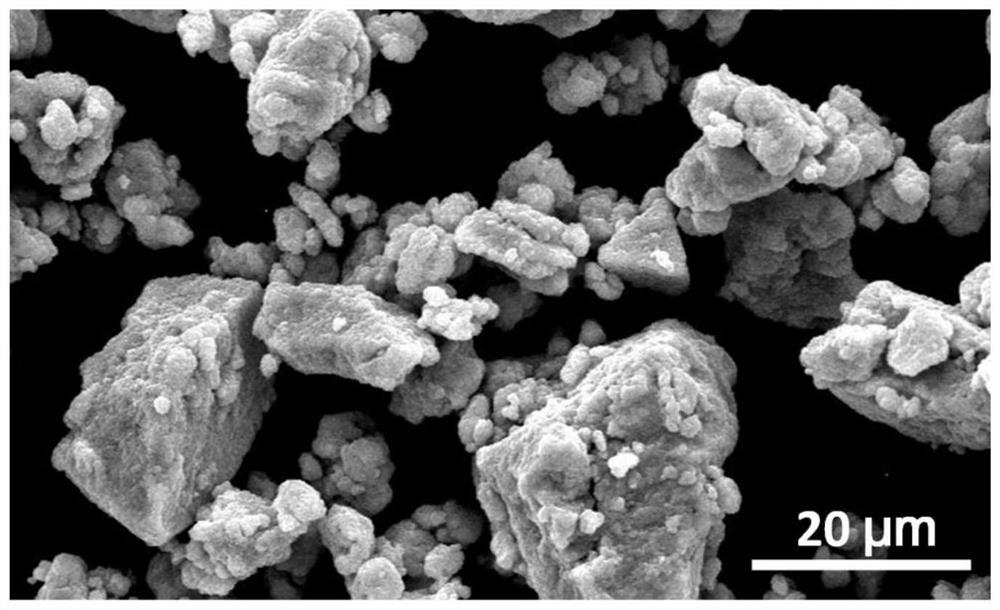

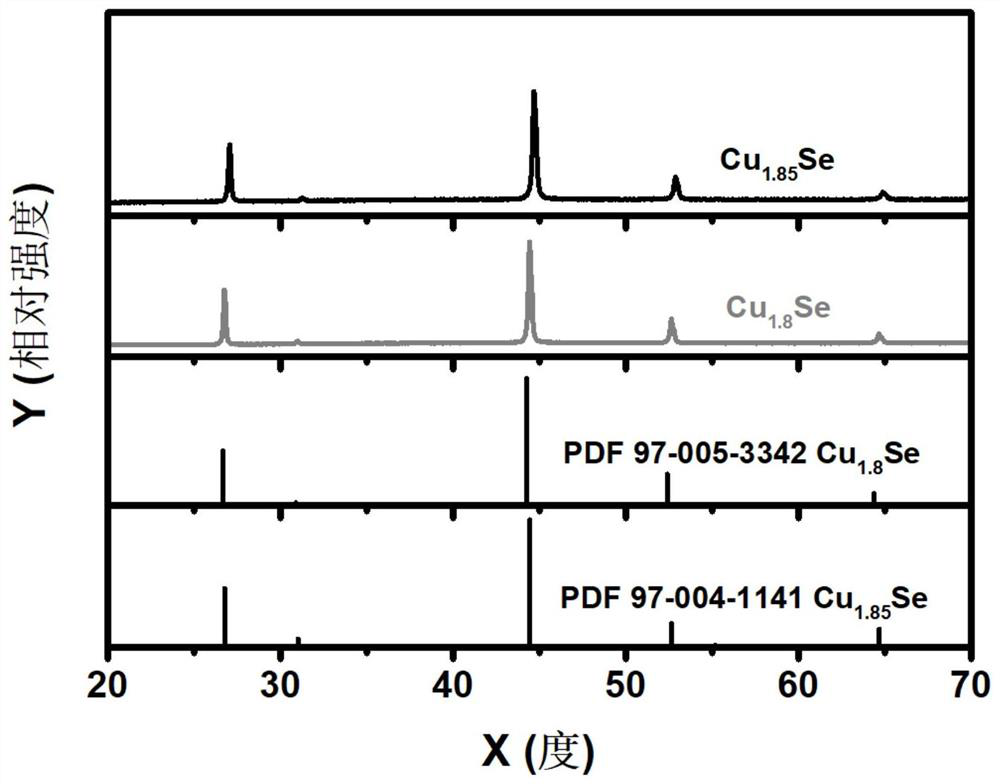

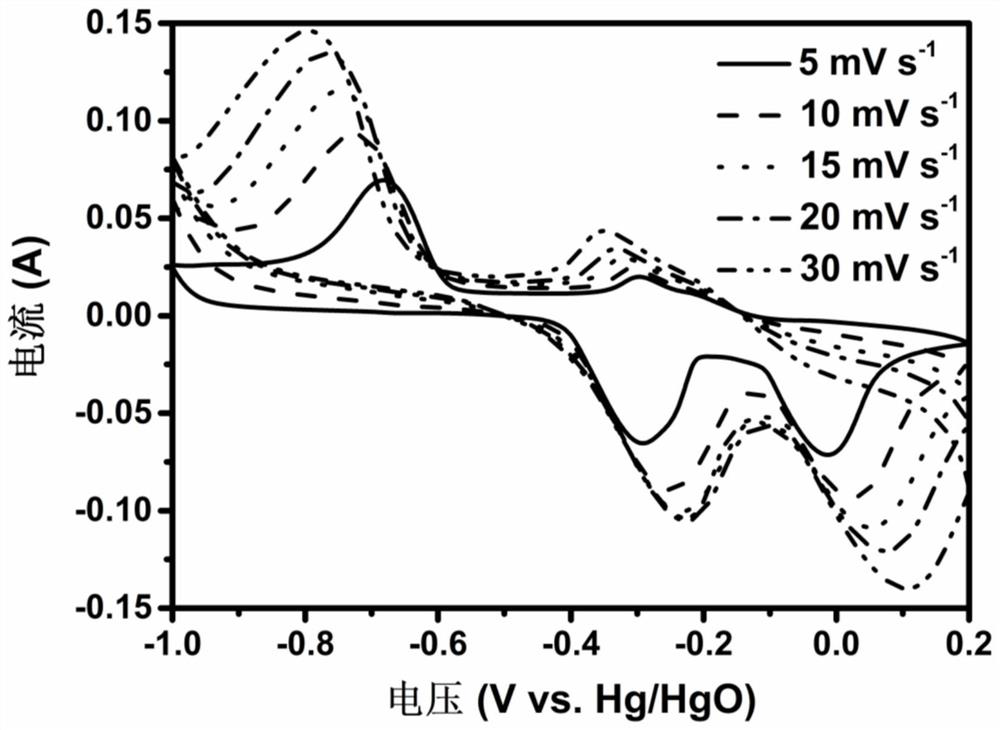

[0018] Step 1: High-purity elemental Cu and Se are used as starting materials, according to the stoichiometric ratio of Cu 1.85 Se weighing, at this time x=0.15, put the weighed raw materials into a ball ink tank equipped with grinding balls in an argon atmosphere and seal it; put the above ball mill tank with raw materials into a high-energy ball mill for 10h to perform alloy grinding to obtain nano-sized powder;

[0019] Step 2: Cu obtained in Step 1 1.85 Se powder was placed in an agate mortar, according to Cu 1.85 Se powder: acetylene black: polyvinylidene fluoride at a ratio of 7:2:1 Add acetylene black and polyvinylidene fluoride, and add 0.5mL ~ 0.7mL N-methylpyrrolidone dropwise, mix everything and then fully Grind for 0.5 hour to obtain mixed slurry;

[0020] Step 3: evenly scrape the mixed slurry obtained in step 2 on the surface of nickel foam treated with deionized water and alcohol ultrasonic treatment (the surface density of foam nickel is 290~430g / m2, the ape...

Embodiment 2

[0027] Step 1: High-purity elemental Cu and Se are used as starting materials, according to the stoichiometric ratio of Cu 1.8Se weighing, at this time x = 0.2, put the weighed raw materials into a ball ink tank equipped with grinding balls in an argon atmosphere and seal it; put the above ball mill tank with raw materials into a high-energy ball mill for 10 hours of ball milling for alloying to obtain nano-sized powder;

[0028] Step 2: Cu obtained in Step 1 1.8 Se powder was placed in an agate mortar, according to Cu 1.8 Se powder: acetylene black: polyvinylidene fluoride at a ratio of 7:2:1. Add acetylene black and polyvinylidene fluoride, and add 0.5mL~0.7mL N-methylpyrrolidone dropwise. Grind for 0.5 hour to obtain mixed slurry;

[0029] Step 3: evenly scrape the mixed slurry obtained in step 2 on the surface of nickel foam treated with deionized water and alcohol ultrasonic treatment (the surface density of foam nickel is 290 ~ 430g / m2, the aperture is 0.3 ~ 0.7mm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com