Carbon-coated nickel carbide and nickel nano composite material as well as preparation method and application thereof

A nanocomposite material, carbon-coated nickel carbide technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, catalyst activation/preparation, etc. Cumbersome and other problems, to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of carbon-coated nickel carbide and nickel nanocomposite material, comprising the following steps:

[0030] The precursor is prepared by mixing nickel source, nitrogen-free organic carboxylic acid and alkali metal salt;

[0031] The precursor is pyrolyzed in an inert atmosphere to obtain a nanocomposite;

[0032] Among them, the temperature of the pyrolysis is 345°C to 365°C, preferably 345°C to 360°C.

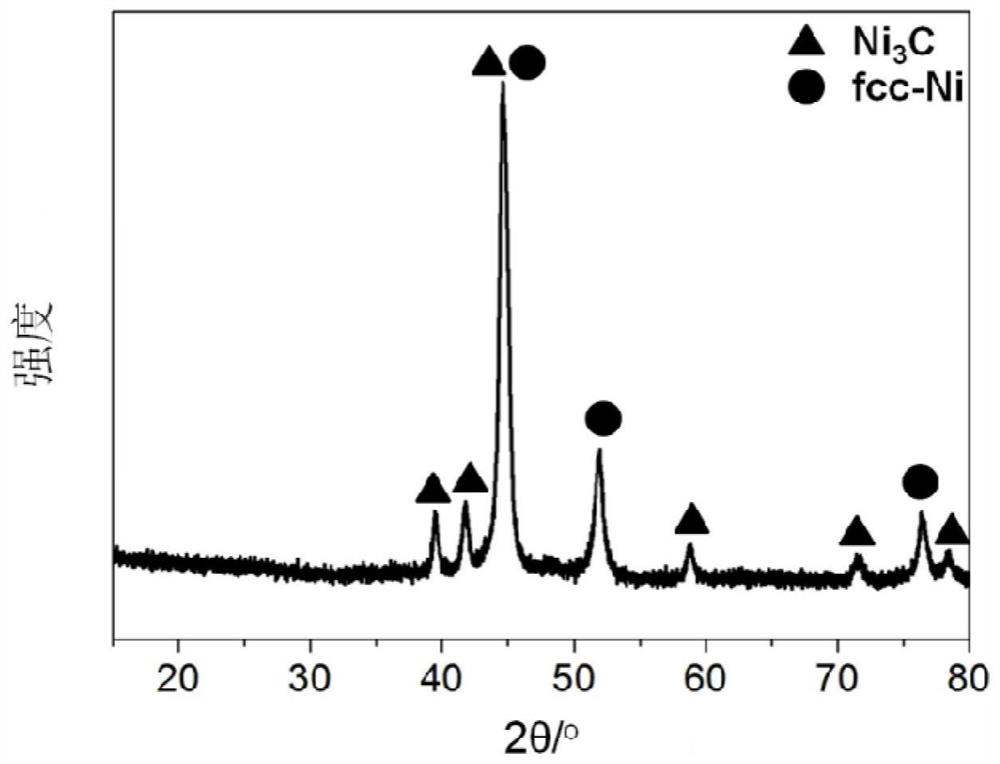

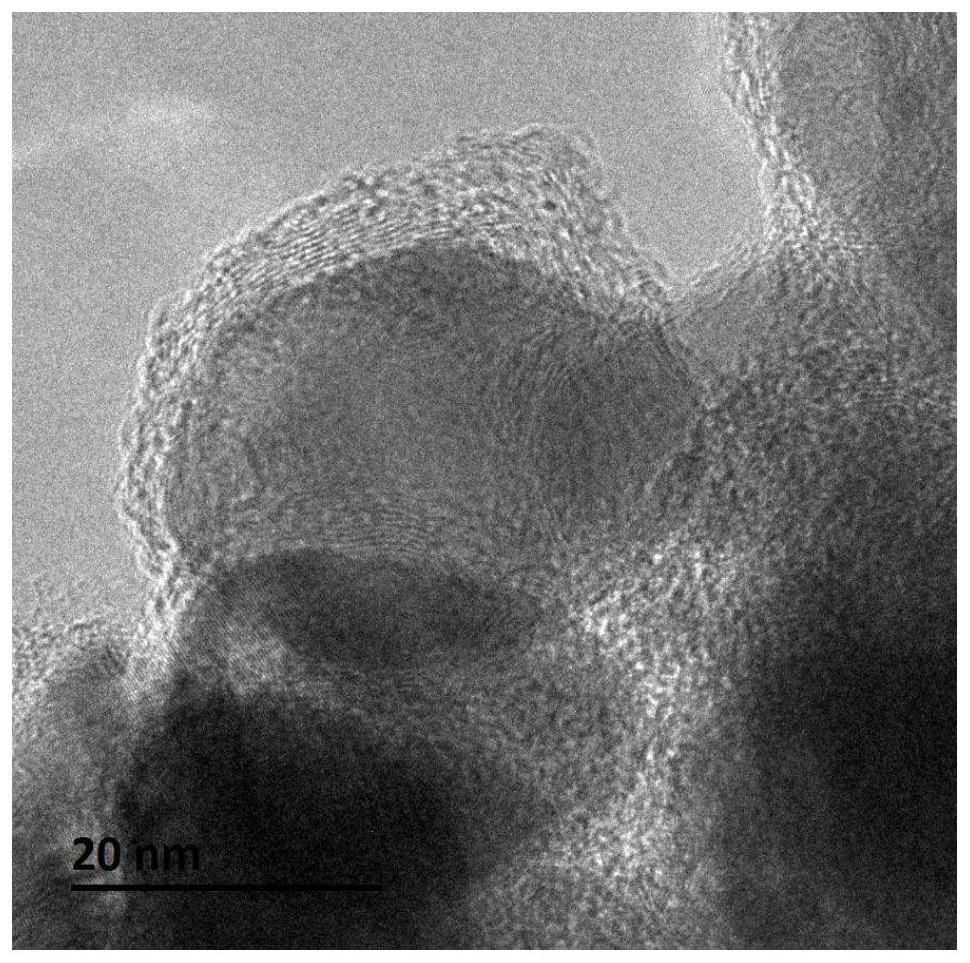

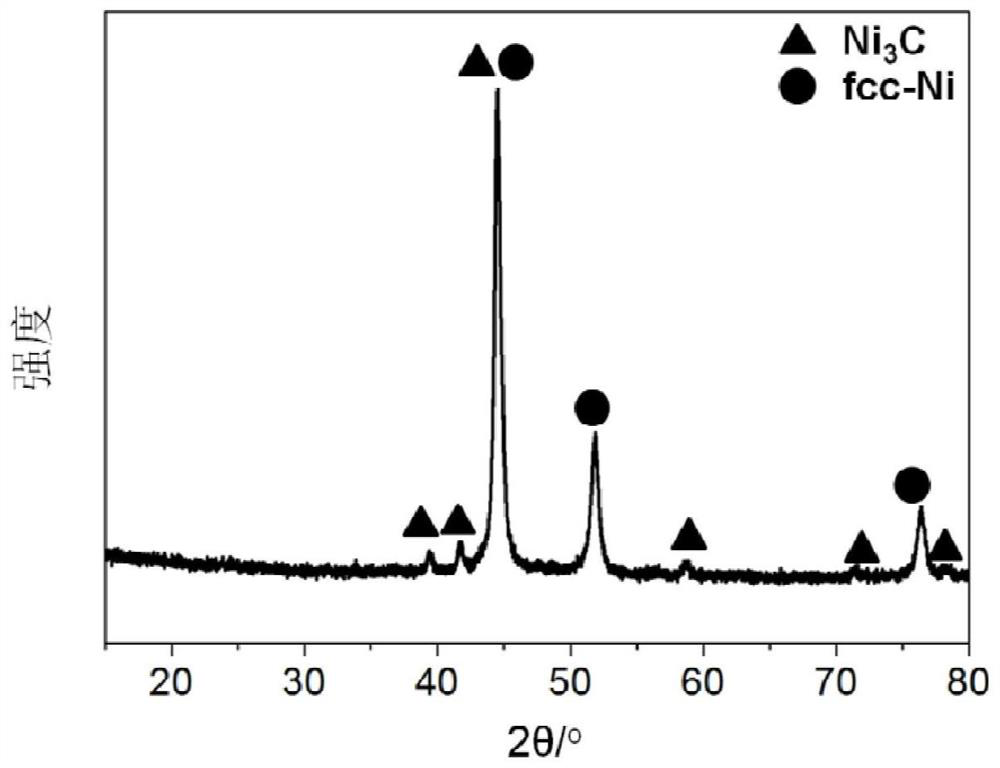

[0033] According to the present invention, the carbon-coated nickel carbide and nickel nanocomposite material prepared by the present invention contains a core-shell structure with a shell layer and an inner core, wherein the shell layer is a carbon layer, and the inner core includes nickel carbide and nickel nanoparticles, The carbon layer contains several layers of graphitized carbon layers. This kind of composite material with both nickel carbide and nickel core can exert many advantages of the material itself and produce...

Embodiment 1

[0053] This example is used to illustrate the preparation of carbon-coated nickel carbide and nickel nanocomposites

[0054] 1) Weigh 10.51g (50mmol) of citric acid monohydrate, 4.64g (50mmol) of nickel hydroxide, 11.69g (200mmol) of sodium chloride into 150mL of deionized water, stir at 110°C to obtain a homogeneous solution, and continue to heat and evaporate. Dry, the solid is ground to obtain the precursor.

[0055] 2) Take 9 g of the precursor obtained in step 1) and place it in a porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed nitrogen, flow 100 mL / min, and heat up to 330 ° C at a rate of 3 ° C / min Then, the temperature was raised to 350°C at a rate of 1°C / min, and the heating was stopped after 150 min at a constant temperature, and cooled to room temperature in a nitrogen atmosphere.

[0056] 3) Transfer the composite material in the porcelain boat of step 2) to a flask, add 50 mL of deionized water, stir at 60° ...

Embodiment 2

[0060] This example is used to illustrate the preparation of carbon-coated nickel carbide and nickel nanocomposites

[0061] 1) Weigh 10.51g (50mmol) citric acid monohydrate, 4.64g (50mmol) nickel hydroxide, 5.84g (100mmol) sodium chloride into 150mL deionized water, stir at 110°C to obtain a homogeneous solution, and continue to heat and steam. Dry, the solid is ground to obtain the precursor.

[0062] 2) Get 7g of the precursor obtained in step 1) and place it in a porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed nitrogen, flow 100 mL / min, and be warming up to 330 at a rate of 3°C / min After 1 °C, the temperature was raised to 350 °C at a rate of 1 °C / min, and the heating was stopped after 150 min at a constant temperature, and cooled to room temperature in a nitrogen atmosphere.

[0063] 3) Transfer the composite material in the porcelain boat of step 2) to a flask, add 50 mL of deionized water, stir at 60° C. for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com