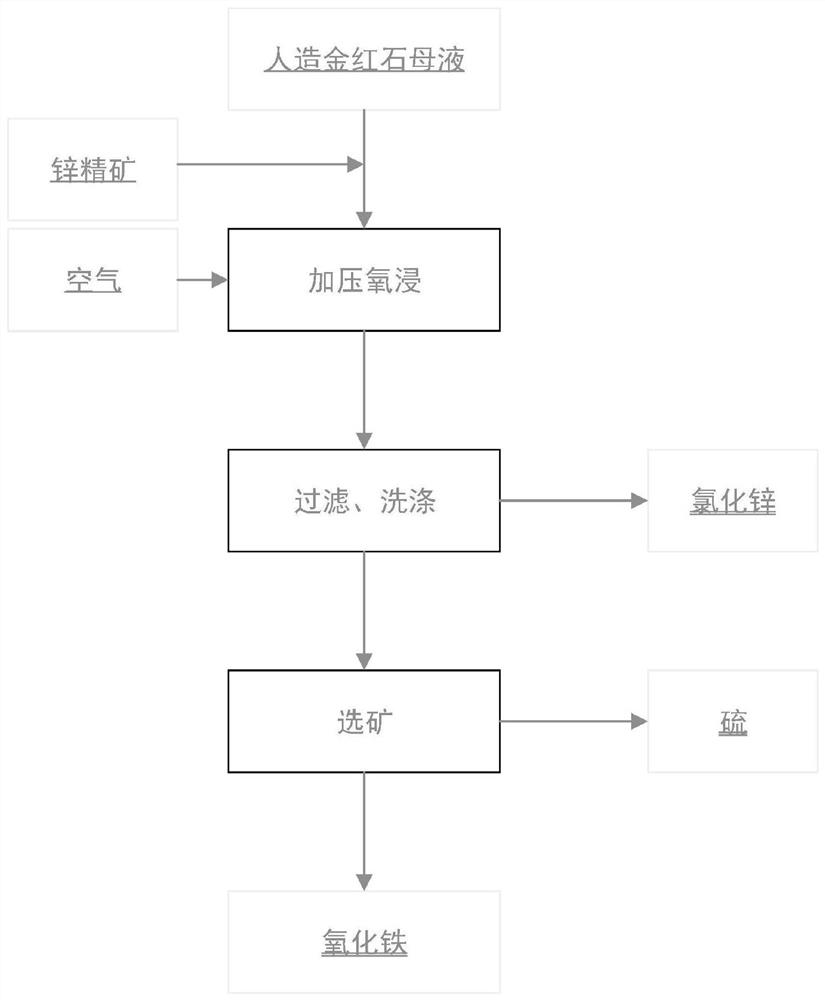

Method for comprehensively utilizing artificial rutile mother liquor in zinc concentrate treatment

A technology of artificial rutile and zinc concentrate, applied in the preparation/purification of zinc halide, sulfur, iron oxide, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Measure 100mL of the above-mentioned artificial rutile mother liquor, put it into a 300mL polytetrafluoroethylene pressure leaching tank, add 30g of zinc concentrate, put the pressure leaching tank in a 140°C oven at a constant temperature for 3 hours, and add Oxygen is passed through the pressure tank to ensure that the pressure in the tank is 0.65Mpa, and then solid-liquid separation is carried out, and the filtrate is zinc chloride solution; the solid phase is separated by cyclone to obtain elemental sulfur and iron oxide.

[0037] After testing, the obtained zinc chloride solution contains zinc 97.23g / L, iron content 1.08g / L, residual acid HCL is 1.86%, zinc recovery rate 97.20%; the S content of gained elemental sulfur is 95.30%, iron content 2.24%, The sulfur recovery rate is 95.20%; the total iron content of the obtained iron oxide is 59.84%, and the sulfur content is 2.00%.

Embodiment 2

[0039] Measure 150mL of the above-mentioned artificial rutile mother liquor, put it into a PTFE pressure leaching tank with a volume of 300mL, add 30g of zinc concentrate, put the pressure leaching tank into a 140°C oven at a constant temperature for 3 hours, and add Oxygen is passed through the pressure tank to ensure that the pressure in the tank is 0.65Mpa, and then solid-liquid separation is carried out, and the filtrate is zinc chloride solution; the solid phase is separated by cyclone to obtain elemental sulfur and iron oxide.

[0040] After testing, the obtained zinc chloride solution contains zinc 64.69g / L, iron content 3.28g / L, residual acid HCL is 2.64%, zinc recovery rate 97.80%; the S content of gained elemental sulfur is 96.70%, iron content 1.68%, The sulfur recovery rate is 96.62%; the total iron content of the obtained iron oxide is 61.64%, and the sulfur content is 1.46%.

Embodiment 3

[0042] Measure 100mL of the above-mentioned artificial rutile mother liquor, put it into a PTFE pressure leaching tank with a volume of 300mL, add 60g of zinc concentrate, put the pressure leaching tank in a 140°C oven at a constant temperature for 3 hours, and add Oxygen is passed through the pressure tank to ensure that the pressure in the tank is 0.65Mpa, and then solid-liquid separation is carried out, and the filtrate is zinc chloride solution; the solid phase is separated by cyclone to obtain elemental sulfur and iron oxide.

[0043] After testing, gained zinc chloride solution contains zinc 146.48g / L, iron content 2.49g / L, residual acid HCL is: 0.96%, zinc recovery rate 77.26%; The S content of gained elemental sulfur is 91.22%, iron content 4.58% , the sulfur recovery rate is 72.35%; the total iron content of the obtained iron oxide is 25.80%, and the sulfur content is 3.64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com