Chromium slag treatment process

A treatment process and technology for chromium slag, applied in sustainable waste treatment, chromium compounds, solid waste management, etc., can solve the problems of large amount of reducing agent ferrous sulfate, acid can not be recycled, pollution, etc., to achieve low cost, reduce The effect of water consumption and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

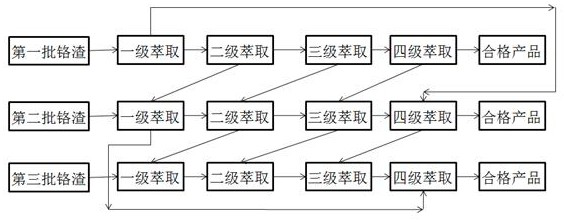

[0021] Example 1: A kind of chromium slag treatment process

[0022] Specific steps are as follows:

[0023] Treatment of the first batch of chrome slag

[0024] 1.1 1T chromium slag (hexavalent chromium 1656mg / L), after crushing, add 5T water, temperature 70℃, stir for 4 hours, filter (press filter), 1.3T filter cake, 4.7T dark yellow filtrate (hexavalent chromium 256mg / L) ) Add sodium bisulfite to reduce to dark green, adjust pH7, produce chromium hydroxide precipitation, after filtration, the filter cake is gray chromium hydroxide, the pH of the filtrate is adjusted to neutral, and the second batch of materials is extracted for four-stage extraction as extract use;

[0025] 1.2 1.3T filter cake (255mg / L of hexavalent chromium) continued secondary extraction, add 5T of water, temperature 70℃, stir for 4 hours, filter (press filter), 1.1T filter cake, 5.1T filtrate (hexavalent chromium 51mg / L) L) for the first-level extraction of the second batch of materials as an extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com