Styrene-(methyl)acrylate copolymer as well as preparation method and application thereof

An acrylate and copolymer technology, applied in the field of polymers, can solve problems such as difficult to meet performance requirements, low melt strength, low molecular weight of MS polymers, etc., to achieve improved entanglement ability, improved processing performance, and low hygroscopicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

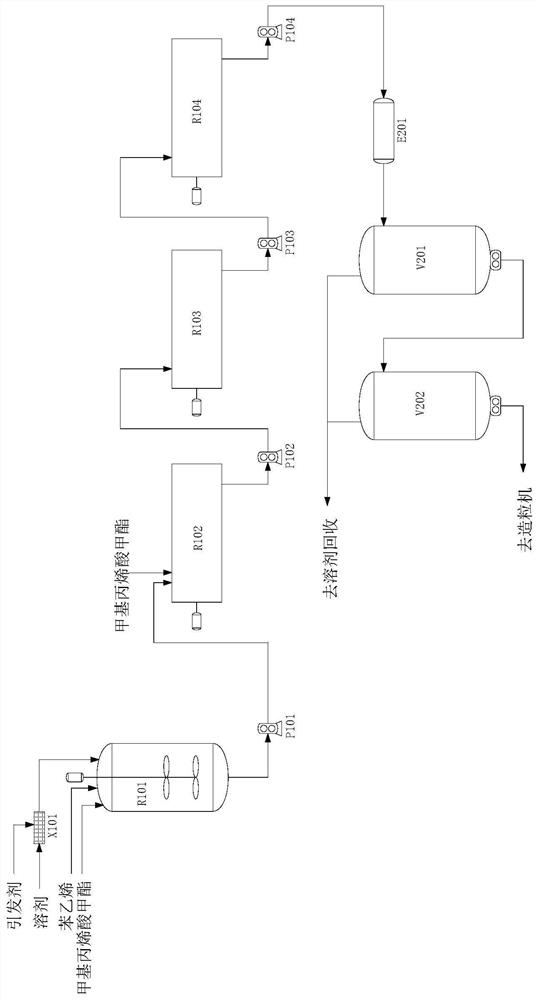

[0026] A second aspect of the present invention provides a method for preparing a styrene-(meth)acrylate copolymer, the method comprising: carrying out a styrene-based monomer and a (meth)acrylate-based monomer under an initiator system polymerization to obtain the styrene-(meth)acrylate copolymer; based on the total weight of the monomers, the amount of the styrene-based monomer is 10wt% to 95wt%, preferably 30wt% to 90wt%, More preferably 50wt% to 80wt%, the amount of the (meth)acrylate monomer is 5wt% to 90wt%, preferably 10wt% to 70wt%, more preferably 20wt% to 50wt%; and, the The total amount of styrene-based monomers and the (meth)acrylate-based monomers is more than 90wt%;

[0027] Wherein, the initiator system contains a multifunctional initiator, and the multifunctional initiator has more than three functional groups that can form free radicals, and, based on the total weight of the initiator system, the content of the multifunctional initiator 50 wt% or more.

[00...

Embodiment approach

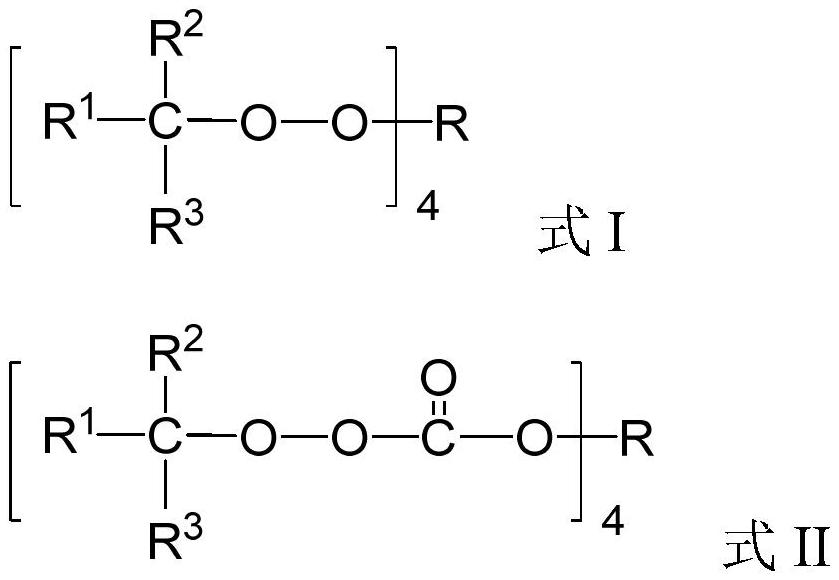

[0030] According to a preferred embodiment of the present invention, the multifunctional initiator is a tetrafunctional peroxide having a structure shown in formula I or a structure shown in formula II;

[0031]

[0032] Wherein, R is a multifunctional group core, such as cyclohexyl, dicyclohexylpropanyl, R 1 , R 2 , R 3 each independently substituted or unsubstituted C 1 ~C 5 alkyl.

[0033] In the present invention, various four-functional peroxide initiators conventional in the art can be selected, which can be self-made or commercially purchased. Specifically preferably, the initiator is 2,2-bis(4,4-bis(tert-butylperoxy)cyclohexyl)propane, [6,6-bis(5-a-bromoisobutyryloxy- At least one of 2-oxopentane)-4,8-dioxundecanediol 1,11] bis(a-bromoisobutyrate) and tetra-t-butyl peroxytetracarbonate. The tetra-t-butyl peroxytetracarbonate is, for example, commercialized JWEB50.

[0034]In the present invention, monofunctional peroxides, bifunctional peroxides and multifunc...

Embodiment 1

[0059] The mass ratio of styrene monomer and methyl methacrylate monomer is 7:3, the amount of solvent ethylbenzene accounts for 8wt% of the total amount of the reaction system, and the initiator is selected from four functional group peroxides 2,2-bis(4,4 - Di(tert-butylperoxy)cyclohexyl)propane in an amount of 800 ppm (relative to styrene monomer). The polymerization temperature in the first reactor (CSTR) is 106° C., the pressure is 0.05 MPaA, and when the monomer conversion rate reaches 21%, the reaction mixture is pumped into the second reactor (PFR). The polymerization temperature in the second reactor is 120-135° C., the pressure is 2.1 MPaA, and the monomer conversion rate is 46%, the reaction mixture is pumped into the third reactor (PFR). The polymerization temperature of the third reactor is 135-154°C, the pressure is 1.5MPaA, and when the monomer conversion rate is 71%, the reaction mixture is pumped into the fourth reactor (PFR); the polymerization temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com