Blasting vibration characteristic parameter prediction method based on SA-GA-BP

A technology of blasting vibration and characteristic parameters, applied in neural learning methods, genetic models, genetic laws, etc., can solve the problems of falling into local optimal solutions, nonlinearity, uncertainty, etc., and achieve high convergence speed and high prediction accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

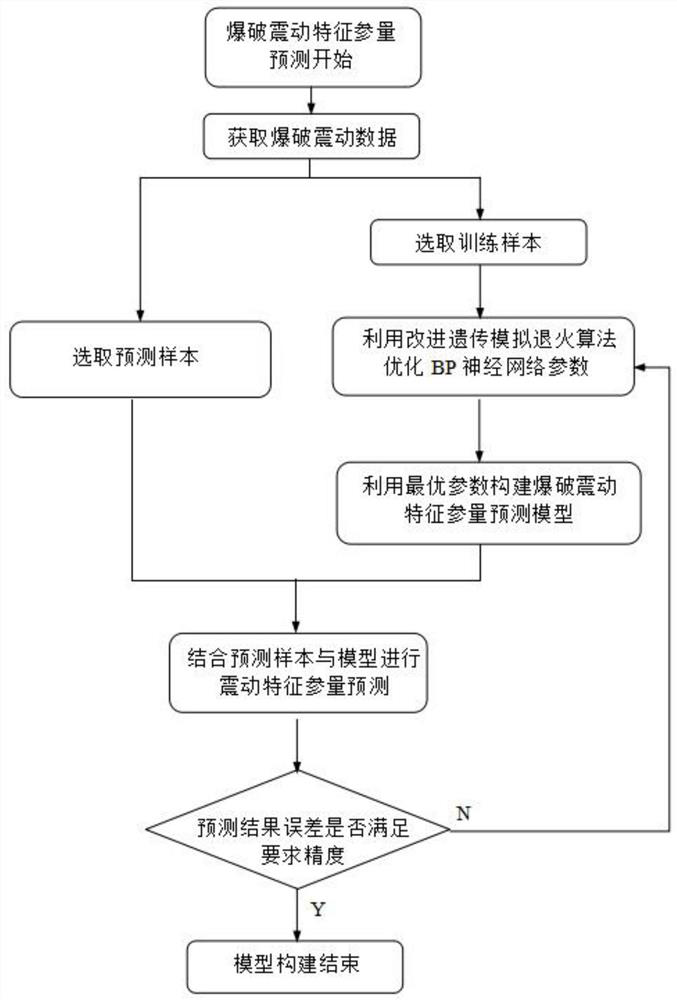

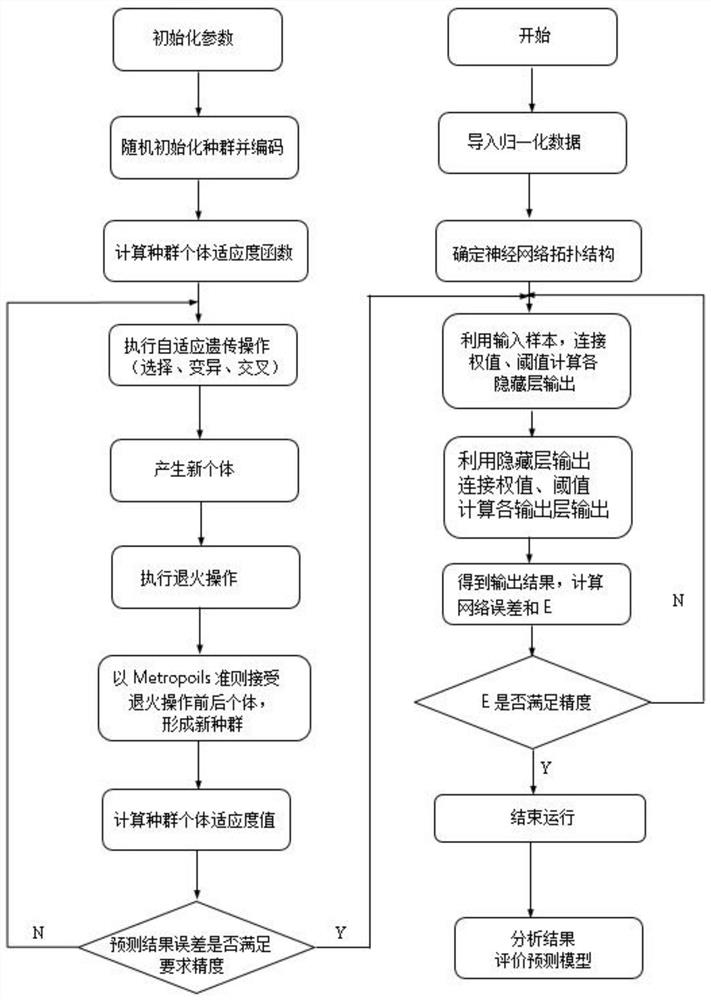

[0035] Embodiment 1: as figure 1 As shown, a method for predicting characteristic parameters of blasting vibration based on SA-GA-BP, the specific steps are as follows:

[0036] (1) Obtain the influencing factors of blasting vibration in the blasting engineering site: hole spacing, row spacing, hole diameter, hole depth, filling, chassis resistance line, total charge amount, maximum section charge amount, unit consumption, elevation difference, blast source distance and rock physical and mechanical properties, according to the principal analytic hierarchy process to determine the hole depth, filling, chassis resistance line, elevation difference, blast source distance, total charge, the maximum section of charge as input parameters, and the blasting vibration peak velocity and main frequency Construct a data set for the output parameters as a training sample and a prediction sample; due to the different physical dimensions, the original data of the data set constructed by the ...

Embodiment 2

[0075] Embodiment 2: This embodiment further illustrates the technical solution provided by the present invention in conjunction with specific examples;

[0076] In this example, the blasting vibration test of an open-pit mine side wall treatment project is taken as the research object. The project is located in Honghe Prefecture, Yunnan Province; m, the chassis resistance line is 3-5m, the step height is 8-15m, and the detonation network selects the electronic detonator-nonel hybrid detonation network;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com