Flue gas purification device for rubber processing

A flue gas purification and extraction device technology, applied in the field of air purification, can solve the problems of no effective treatment of harmful gases and bacteria, simple structure of the flue dust purification device, environmental impact, etc., and achieve low device cost, good cleaning effect, The effect of high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

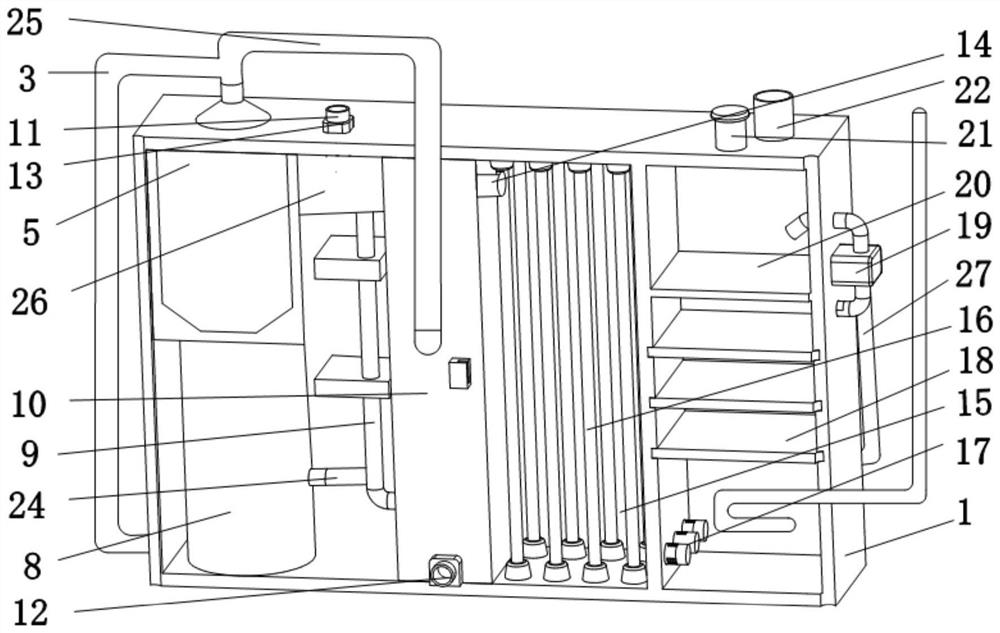

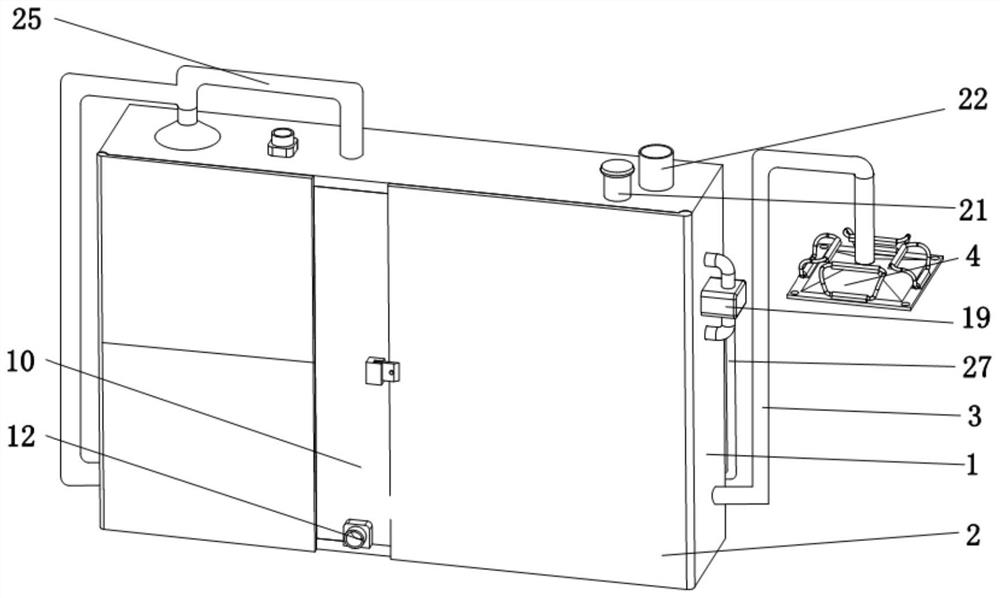

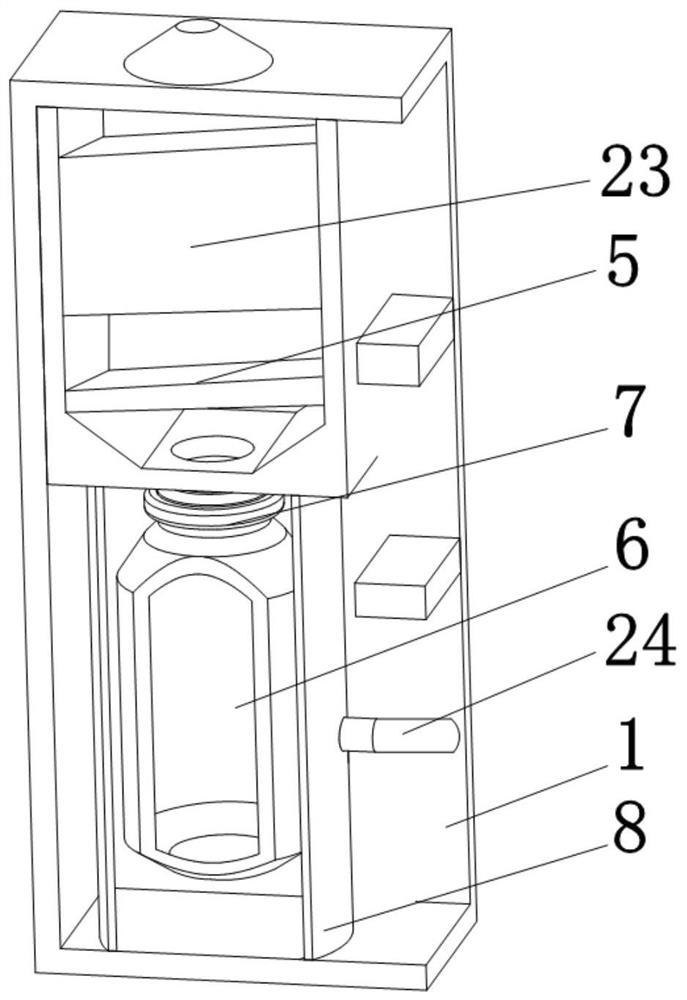

[0027] Such as Figure 1 to Figure 5As shown, the present invention provides a flue gas purification device for rubber processing, including a purification cabinet 1, and both ends of the front of the chemical cabinet 1 are provided with hinge doors 2, and the hinge doors 2 can clean the whole purification cabinet well. 1. Necessary protection is carried out for the internal area. It is also very convenient and easy when the internal structure needs to be disa...

no. 2 example

[0030] Based on the flue gas purification device for rubber processing provided in the first embodiment, due to the high flue gas content in the rubber flue gas production process, and the acidity produced by the metabolism of aerobic activated sludge in the bioabsorption box 10 The ionic solution can decompose the rubber fume in the gas injection pipe 3 very well. In order to further improve the purification efficiency, increase the connection between the device components, and realize the pretreatment of the rubber fume, this one is used for rubber The processed flue gas purification device also includes a second guide pipe 25 connected to one side of the biological absorption box 10, a water pump is provided at the other end of the second guide pipe 25, and a one-way valve is provided at the water outlet of the water pump. The water outlet of the water outlet is provided with a spraying device, and the water outlet of the spraying device is connected with the gas injection p...

no. 3 example

[0033] Basically, the second embodiment provides a flue gas purification device for rubber processing. If the flue gas content in the device gradually increases and the discharge is unfavorable, the purification efficiency will be reduced, the entire device will also be in a supersaturated state, and the internal pressure of the device will Too high will also affect the internal equipment, wherein the activity of the activated carbon in the activated carbon adsorption chamber 18 and the aerobic activated sludge in the biological absorption box 10 plays a vital role in the purification of the flue gas. The working efficiency of the device can improve the activity of the activated carbon in the activated carbon adsorption chamber 18 and the aerobic activated sludge in the biological absorption box 10. This flue gas purification device for rubber processing also includes: the gas injection pipe 3 passes through the purification cabinet 1 One side enters the activated carbon adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com