Polysulfone-based membrane, reverse osmosis composite membrane containing polysulfone-based membrane and preparation method

A technology of reverse osmosis composite membrane and polysulfone-based membrane, applied in the field of reverse osmosis composite membrane, can solve problems such as performance stability and service life gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

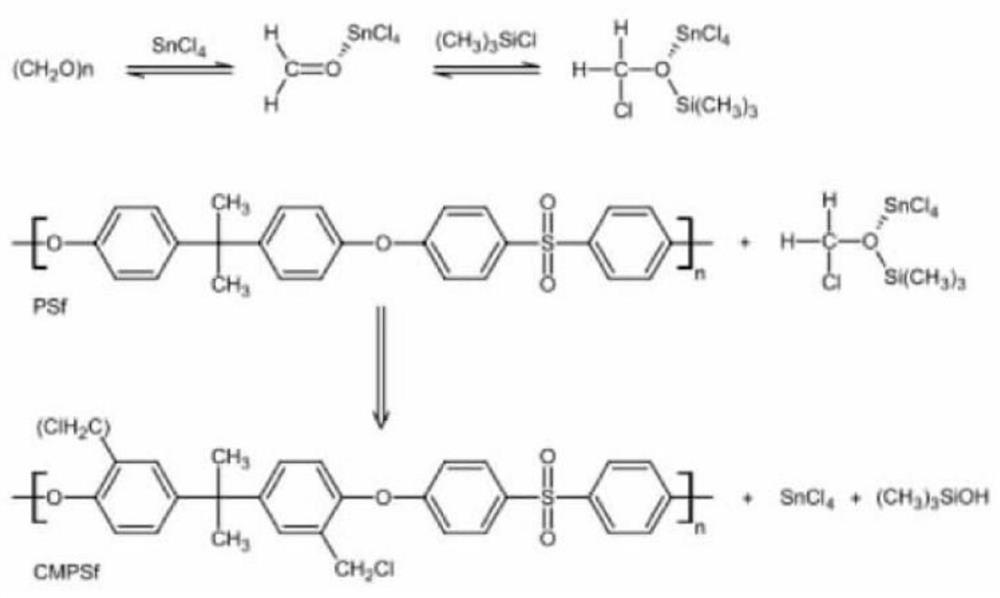

[0117] 1. Preparation of chloromethylated polysulfone: Weigh 900g of polysulfone and place it in a reaction kettle, add 15L of chloroform to dissolve it, pass nitrogen protection in the reaction kettle, and then add paraformaldehyde and trimethyl chloride with a mass ratio of 1:2 A total of 450g of silane was added, and finally 180ml of tin tetrachloride was added and reacted at 20°C for 72 hours. After the reaction, the product is poured into a methanol solution for reverse precipitation, and the precipitated product is washed with reverse osmosis (RO) water, and then dried in a vacuum oven to obtain chloromethylated polysulfone. The obtained chloromethylated polysulfone The degree of substitution is 0.86mmol / g.

[0118] 2. Preparation of chloromethylated polysulfone base membrane: prepare a casting solution with a mass fraction of chloromethylated polysulfone of 17.5%, and the solvent is dimethylformamide. The casting liquid is coated on a non-woven fabric with a thickness ...

Embodiment 2

[0123] 1. Preparation of chloromethylated polysulfone: Weigh 900g of polysulfone and place it in a reaction kettle, add 15L of chloroform to dissolve it, pass nitrogen protection in the reaction kettle, and then add paraformaldehyde and trimethyl chloride with a mass ratio of 1:2 A total of 450g of silane was added, and finally 180ml of tin tetrachloride was added and reacted at 20°C for 72 hours. After the reaction, the product is poured into a methanol solution for reverse precipitation, and the precipitated product is washed with reverse osmosis (RO) water, and then dried in a vacuum oven to obtain chloromethylated polysulfone. The obtained chloromethylated polysulfone The degree of substitution is 0.86mmol / g.

[0124] 2. Preparation of polysulfone grafted with octaamino POSS on the surface: a casting solution with a mass fraction of chloromethylated polysulfone of 17.5% was prepared, and the solvent was dimethylformamide. The casting solution is coated on a glass slide, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Degree of substitution | aaaaa | aaaaa |

| Degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com