Treatment process for purifying chlorine-containing wastewater by ammonium salt crystallization

A technology for treating process and wastewater, applied in natural water body treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of complicated desalination process, generation of hazardous waste, high energy consumption, etc., and achieve simple process flow and purification effect. Good, less process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

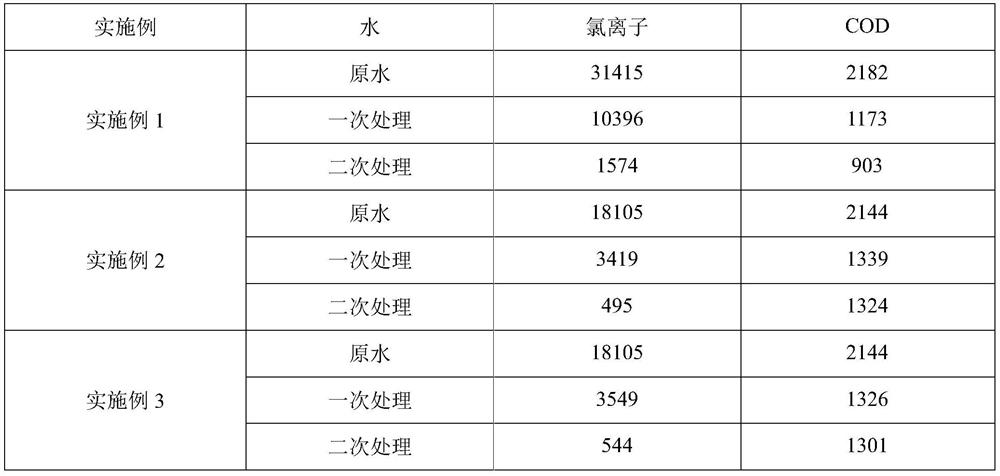

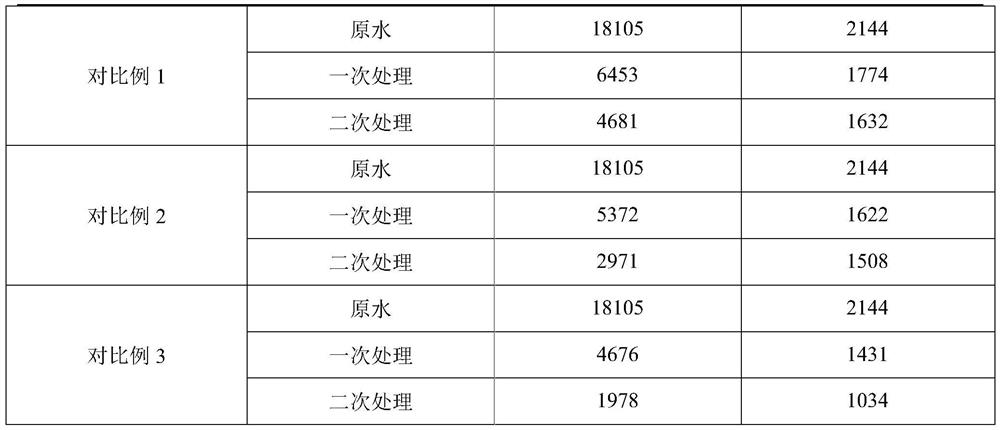

Embodiment 1

[0029] Preparation of chloride ion absorbent: Add 10kg of water-soluble chitosan to 15kg of water, heat to 100°C, add 5kg of bismuth nitrate while stirring, keep the temperature at 100-120°C, then add 1kg of polyvinyl alcohol, p-hydroxystyrene 0.5 kg of ketone and 0.5 kg of 1-methoxy-2-propanol were stirred for 2 hours to obtain a chloride ion absorbent.

[0030] The chlorine ion absorbent of the present embodiment is processed according to the following steps to the collection industrial wastewater of a certain power plant in Tangshan:

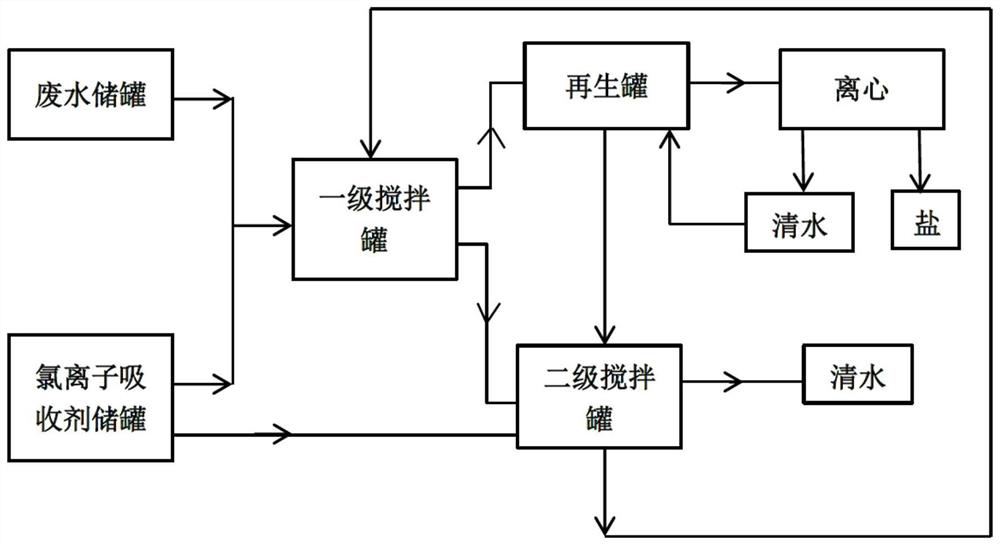

[0031] S1. Chloride ion absorbent and waste water enter the first-stage mixing tank at the same time, stir evenly and then stand and separate;

[0032] S2. The waste water treated by the primary stirring enters the secondary stirring tank, and at the same time, fills the secondary stirring tank with new chloride ion absorbent, stirs evenly and then leaves it to stratify to obtain the treated waste water;

[0033] S3. The chlorine ion absorbe...

Embodiment 2

[0036] Preparation of chloride ion absorbent: Add 15kg of water-soluble chitosan to 30kg of water, heat to 100°C, add 8kg of bismuth nitrate while stirring, keep the temperature at 100-120°C, then add 2kg of polyvinyl alcohol, p-hydroxystyrene 1 kg of ketone and 1 kg of 1-methoxy-2-propanol were stirred for 2 hours to obtain a chloride ion absorbent.

[0037] The chlorine ion absorbent of the present embodiment is processed according to the following steps to the collection industrial wastewater of a power plant in Baoding:

[0038] S1. Chloride ion absorbent and waste water enter the first-stage mixing tank at the same time, stir evenly and then stand and separate;

[0039] S2. The waste water treated by the primary stirring enters the secondary stirring tank, and at the same time, fills the secondary stirring tank with new chloride ion absorbent, stirs evenly and then leaves it to stratify to obtain the treated waste water;

[0040] S3. The chlorine ion absorbent separated ...

Embodiment 3

[0043] Preparation of chloride ion absorbent: add 12kg of water-soluble chitosan to 20kg of water, heat to 100°C, add 7kg of bismuth nitrate while stirring, keep the temperature at 100-120°C, then add 1.5kg of polyvinyl alcohol, p-hydroxybenzene 0.8 kg of ethyl ketone and 0.8 kg of 1-methoxy-2-propanol were stirred for 2 hours to obtain a chloride ion absorbent.

[0044] The chlorine ion absorbent of the present embodiment is processed according to the following steps to the industrial waste water used in embodiment 2:

[0045] S1. Chloride ion absorbent and waste water enter the first-stage mixing tank at the same time, stir evenly and then stand and separate;

[0046] S2. The waste water treated by the primary stirring enters the secondary stirring tank, and at the same time, fills the secondary stirring tank with new chloride ion absorbent, stirs evenly and then leaves it to stratify to obtain the treated waste water;

[0047] S3. The chlorine ion absorbent separated from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com