Cement concrete pavement rapid repair material and preparation method thereof

A technology for cement concrete and repairing materials, applied in the field of materials, can solve the problems of repairing material road surface not being able to restore traffic in time, poor bonding performance of old and new materials, and reduced strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

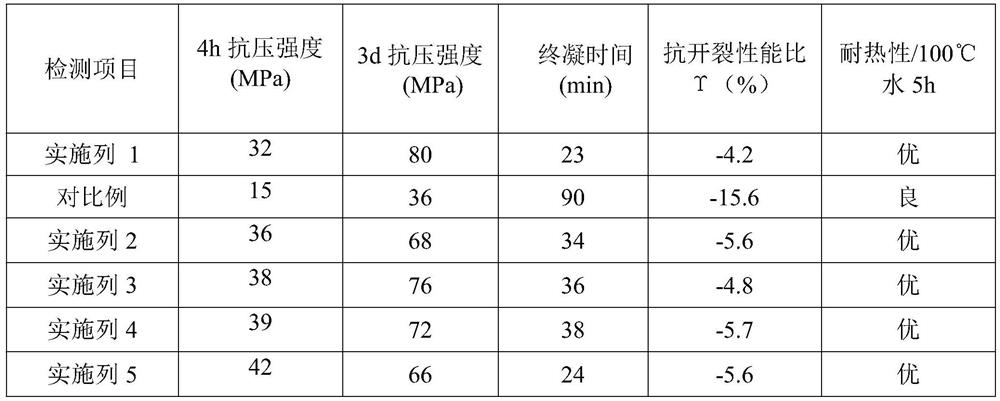

Examples

Embodiment 1

[0041] Put 0.07 parts of modified carbon nanofibers, 0.06 parts of dispersant and 9 parts of water in 17 parts of composite alkali activator solution, stir for 240s, and then put it under the power of 900W for 50min to obtain a uniform mixed solution; then weigh 50 parts of fly ash, 14 parts of granulated blast furnace slag, 6 parts of red mud, 3 parts of rice husk ash, and 0.1 part of co-solvent were poured into the stirring pot and stirred for 90 seconds to obtain the mixture; then the uniform mixed solution obtained above was added to The mixture was stirred for 90 seconds to obtain a geopolymer slurry, and finally 1 part of silane coupling agent was added thereto, stirred for 180 seconds, then poured, vibrated, and cured under natural conditions to obtain the rapid road surface repair material.

Embodiment 2

[0045] Put 0.06 parts of modified carbon nanofibers, 0.05 parts of dispersant and 9 parts of water in 17 parts of composite alkali activator solution, stir for 240s, and then put it under the power of 900W for 60min to obtain a uniform mixed solution; then weigh 54 parts of fly ash, 10 parts of granulated blast furnace slag, 6 parts of red mud, 3 parts of rice husk ash, and 0.2 parts of co-solvent were poured into the stirring pot, and stirred for 120s to obtain the mixture; then the uniform mixed solution obtained above was added to The mixture was stirred for 90 seconds to obtain a geopolymer slurry, and finally 1 part of silane coupling agent was added thereto, stirred for 180 seconds, then poured, vibrated, and cured under natural conditions to obtain the rapid road surface repair material.

Embodiment 3

[0047]Put 0.06 parts of modified carbon nanofibers, 0.05 parts of dispersant and 9 parts of water in 20 parts of composite alkali activator solution, stir for 240s, and then put it under the power of 1000W for 55min to obtain a uniform mixed solution; then weigh 52 parts of fly ash, 9 parts of granulated blast furnace slag, 6 parts of red mud, 3 parts of rice husk ash, and 0.1 part of co-solvent were poured into the stirring pot, and stirred for 120s to obtain the mixture; then the uniform mixed solution obtained above was added to The mixture was stirred for 90 seconds to obtain a geopolymer slurry, and finally 1 part of silane coupling agent was added thereto, stirred for 240 seconds, then poured, vibrated, and cured under natural conditions to obtain the rapid pavement repair material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com