Method for removing trace sulfide in benzene

A sulfide, trace technology, applied in chemical instruments and methods, chemical/physical processes, organic chemistry, etc., can solve problems affecting continuous production, catalyst life reduction, catalyst poisoning, etc., to improve desulfurization efficiency and service life, The reaction conditions are easy to implement and the effect is not easy to be lost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Further, the preparation method of the catalyst comprises the following steps:

[0037] Step 1: Add the first base compound to the first part of water and stir, after dissolving, add CO-520 and cyclohexane with a volume ratio of 1: (2~3) and continue to stir evenly to form microemulsion A;

[0038] Step 2: Add an appropriate amount of hydrochloric acid and the second part of water to the ruthenium salt and / or palladium salt and the auxiliary salt and stir, and add CO-520 and cyclohexane with a volume ratio of 1: (2~3) after dissolving Continue to stir evenly to form microemulsion B;

[0039] Step 3: Mix microemulsion A with microemulsion B, add an appropriate amount of the second alkali compound after stirring for a period of time, continue stirring for a period of time, slowly add an organic amine template and stir evenly to obtain microemulsion C;

[0040] Step 4: Add a certain amount of aluminum source compound to microemulsion C under stirring, after the aluminum s...

Embodiment 1

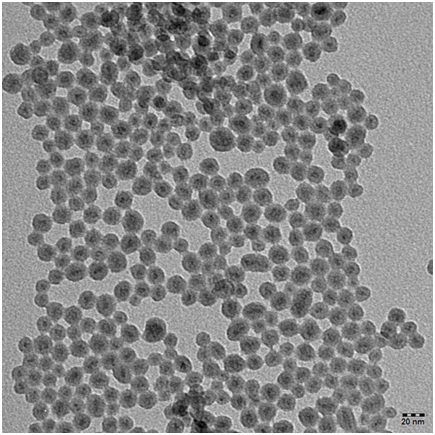

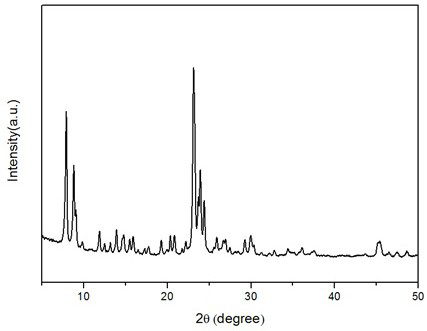

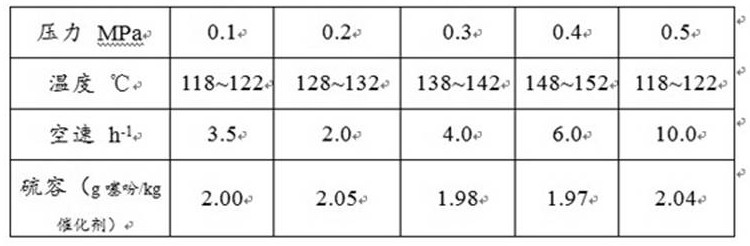

[0051] Add 2.9 g of NaOH to 650 ml of water and stir. After dissolving, add 850 ml of CO-520 and 2550 ml of cyclohexane and continue to stir evenly to form a microemulsion A; Add 0.5ml of hydrochloric acid and 450ml of water to copper nitrate and stir. After dissolving, add 850ml of CO-520 and 2550ml of cyclohexane and continue to stir evenly to form microemulsion B; mix microemulsion A with microemulsion B, and then add 19 ml concentrated ammonia water, continue to stir for a period of time, slowly add 25.0g TPAOH and stir evenly to obtain microemulsion C; add 6.3 g aluminum isopropoxide to microemulsion C under stirring, after the aluminum isopropoxide is uniformly dispersed, slowly Add 320 g TEOS, continue to stir until it becomes white emulsion, then transfer it to a hydrothermal synthesis kettle, and crystallize at 150°C for 72 hours; the crystallized material is separated from solid and liquid, washed, and put into an oven for 5 The temperature was raised to 100°C for 2 ...

Embodiment 2

[0053] Add 2.7 g of NaOH to 400 ml of water and stir. After dissolving, add 800 ml of CO-520 and 1600 ml of cyclohexane and continue stirring to form a microemulsion A; add 1.0 g of ruthenium chloride, 5.4 g of cerium nitrate hexahydrate and 2.1 g of silver nitrate Add 300ml of water and stir. After dissolving, add 1200ml of CO-520 and 2400ml of cyclohexane and continue to stir evenly to form microemulsion B; mix microemulsion A with microemulsion B, add 12 ml of concentrated ammonia after stirring for a while, continue After stirring for a period of time, slowly add 15.7g of TPAOH and stir evenly to obtain microemulsion C; add 7.9 g of aluminum isopropoxide to microemulsion C under the action of stirring, after the aluminum isopropoxide is uniformly dispersed, slowly add 320 g of TEOS, continue Stir until it becomes a white emulsion, then transfer it to a hydrothermal synthesis kettle, and crystallize at 150°C for 72 hours; the crystallized material is separated from solid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com