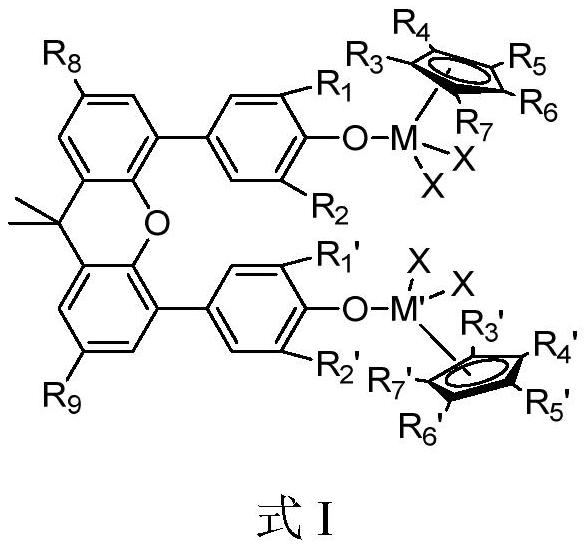

Catalyst for ethylene polymerization and application thereof

A technology of ethylene polymerization and catalyst, which is applied in the field of olefin polymerization and can solve the problem of demanding ligand substituents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

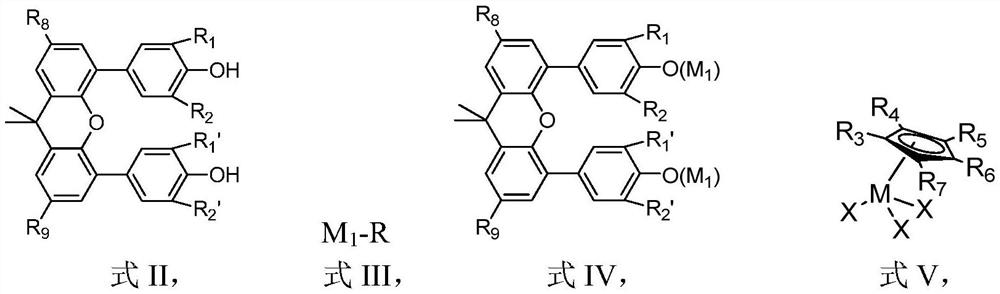

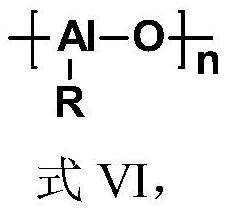

Method used

Image

Examples

Embodiment 1

[0073] Preparation of bisphenol metal complex 7

[0074] Dissolve bisphenol compound 3 (2.24mmol) in ether solvent, add pure KH solid (8.96mmol) to the solution at -78°C and react for 1 hour, return to room temperature, and continue to react for 2 hours. Afterwards, the solution was transferred to a dichloromethane solution of metal complex 2 (4.48 mmol) at -78 °C through a double-angled needle, and reacted at this temperature for 1 hour, and then the system was gradually returned to room temperature, and then reacted for 12 Hour. After the reaction was finished, the solvent was removed with a vacuum line, the residue was washed with dichloromethane and filtered through diatomaceous earth, the filtrate was sucked dry, and the crude product was recrystallized with dichloromethane / n-hexane to obtain an orange product (yield 90% ), the orange product is characterized as follows:

[0075] 1 H NMR (CDCl 3 ,400MHz):δ=7.45(dd,J=7.6,2.0Hz,2H,aryl-H),7.25(s,4H,aryl-H),7.14-7.21(m,4...

Embodiment 2

[0079] Preparation of bisphenol metal complex 7

[0080] Dissolve bisphenol compound 3 (2.24mmol) in ether solvent, add pure KH solid (2.24mmol) to the solution at -78°C and react for 1 hour, return to room temperature, and continue to react for 8 hours. Afterwards, the solution was transferred to a dichloromethane solution of metal complex 2 (4.00 mmol) at -78°C through a double-angled needle, and reacted at this temperature for 1 hour, and then the system was gradually returned to room temperature, and then reacted for 18 Hour. After the reaction was finished, the solvent was removed with a vacuum line, the residue was washed with dichloromethane and filtered through diatomaceous earth, the filtrate was sucked dry, and the crude product was recrystallized with dichloromethane / n-hexane to obtain an orange product (yield 61% ).

Embodiment 3

[0082] Preparation of bisphenol metal complex 7

[0083] Dissolve bisphenol compound 3 (2.24mmol) in ether solvent, add pure KH solid (22.4mmol) to the solution at 40°C and react for 1 hour, return to room temperature, and continue to react for 0.5 hour. Afterwards, the solution was transferred to a dichloromethane solution of metal complex 2 (4.93 mmol) at 40°C through a double-angle needle, and reacted at this temperature for 6 hours. After the reaction was completed, the solvent was removed with a vacuum line, and the remaining The product was washed with dichloromethane and filtered through celite, the filtrate was sucked dry, and the crude product was recrystallized with dichloromethane / n-hexane to obtain an orange product (yield 73%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com