Super-hydrophobic radiation cooling film and preparation method thereof

A super-hydrophobic and thin-film technology, which is applied in the field of super-hydrophobic radiation cooling film and its preparation, can solve the problems that affect the radiation cooling effect of materials and do not consider the influence of material cooling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

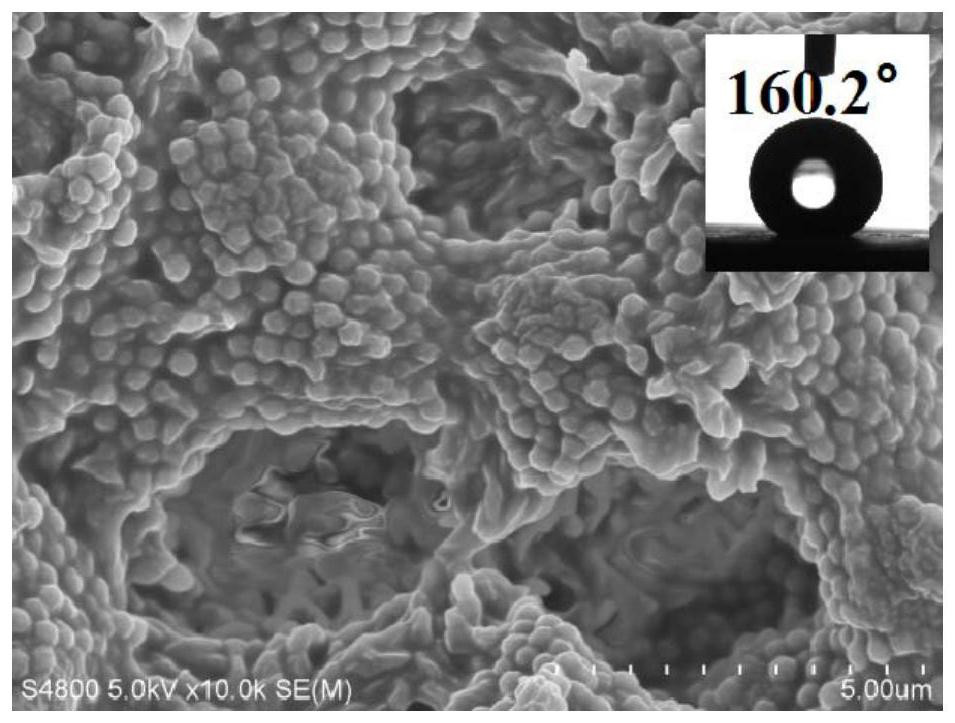

[0035] A method for preparing a superhydrophobic radiation cooling film according to the present invention specifically comprises the following steps:

[0036] Step S1: Weigh a certain amount of PVDF powder, dissolve it in acetone / N,N-dimethylformamide mixed solvent, stir at 40°C for 1-2 hours, and obtain a transparent solution A;

[0037] Step S2: Weigh a certain amount of PDMS prepolymer A and curing agent B component (the mass ratio of component A / B is 10:1) and dissolve it in ethyl acetate solvent, stir at room temperature for 0.5-1.5h to obtain clarification Transparent solution B;

[0038] Step S3: Add the clear and transparent solution described in step S2 to the transparent solution described in step S1 dropwise, keep the beaker sealed, and continue to stir at 40°C for 1-2 hours to obtain a micro-emulsion white suspension. The turbid liquid is polyvinylidene fluoride / polydimethylsiloxane (PVDF / PDMS) composite solution;

[0039] Step S4: Add a certain amount of non-so...

Embodiment 1

[0049] step 1

[0050] Weigh 2.0g of PVDF powder, add it into a mixed solvent of 16g of acetone and 4g of N,N-dimethylformamide, stir magnetically at 40°C for 2h to obtain PVDF transparent solution A; then weigh 1.0g of PDMS prepolymer Body A and 0.1 g of curing agent B were added to 10 g of ethyl acetate, and magnetically stirred at room temperature for 0.5 h to form PDMS clear and transparent solution B.

[0051] step 2

[0052] Add the PDMS clear and transparent solution B described in step 1 into the PVDF transparent solution A drop by drop, keep the beaker sealed, and continue stirring at 40°C for 1 hour to obtain a micro-emulsion white suspension, which is the PVDF / PDMS composite solution.

[0053] step 3

[0054] Use a peristaltic pump to control the dropping rate to 0.4 mL / min, and add 2.0 g of non-solvent water dropwise to the micro-emulsion white suspension in step 2 to form a phase-separated sol.

[0055] step 4

[0056] Cast the phase-separated sol solution o...

Embodiment 2

[0059] step 1

[0060] Weigh 2.0g of PVDF powder, add it to 12g of acetone and 8g of N,N-dimethylformamide mixed solvent, stir magnetically at 40°C for 2h to obtain PVDF transparent solution A; then weigh 1.5g of PDMS prepolymer Body A and 0.15g of curing agent B were added to 10g of ethyl acetate, and magnetically stirred at room temperature for 1.5h to form clear and transparent PDMS solution B.

[0061] step 2

[0062] Add the PDMS clear and transparent solution B described in step 1 into the PVDF transparent solution A drop by drop, keep the beaker sealed, and continue to stir at 40°C for 1.5h to obtain a micro-emulsion white suspension, which is the PVDF / PDMS composite solution.

[0063] step 3

[0064] Use a peristaltic pump to control the dropping rate to 0.4 mL / min, and add 2.5 g of non-solvent water dropwise to the micro-emulsion white suspension in step 2 to form a phase-separated sol.

[0065] step 4

[0066] Cast the phase-separated sol solution obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com