Preparation method of treating agent for improving lubricating effect of drilling fluid

A technology for treating agent and drilling fluid, applied in the field of preparation of treating agent, can solve the problems of high cost, environmental pollution, poor biodegradation performance of mineral oil lubricant, etc., and achieve the effect of increasing service life and reducing adsorption of mud cake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

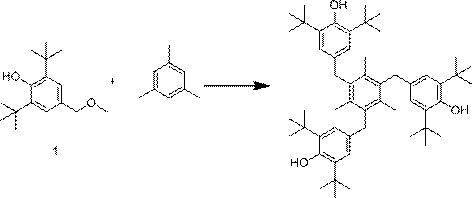

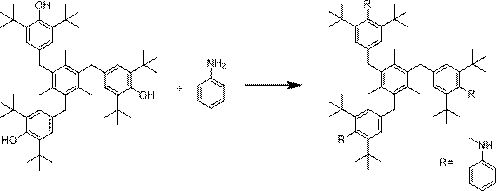

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a treatment agent for improving the lubricating effect of drilling fluid, comprising the following raw materials in parts by weight:

[0038] 5 parts of sodium lauryl sulfate, 10 parts of deionized water, 7 parts of sodium carboxymethylcellulose, 6 parts of polyvinylpyrrolidone, 3 parts of Span 80, 70 parts of lubricating components and 0.6 parts of antioxidant;

[0039] The treatment agent is prepared through the following steps:

[0040] The first step, mixing sodium lauryl sulfate and deionized water, stirring evenly, adding sodium carboxymethylcellulose and polyvinylpyrrolidone to obtain the first mixed solution;

[0041] The second step is to add Span 80 to the lubricating component, then add the antioxidant, and ultrasonically disperse for 30 minutes at a temperature of 40°C and a frequency of 40kHz to obtain the second mixed liquid;

[0042] The third step is to mix the first mixed liquid and the second mixed liquid, and stir for 4-8 hour...

Embodiment 2

[0055] A preparation method of a treatment agent for improving the lubricating effect of drilling fluid, comprising the following raw materials in parts by weight:

[0056] 6 parts of sodium lauryl sulfate, 15 parts of deionized water, 8 parts of sodium carboxymethylcellulose, 7 parts of polyvinylpyrrolidone, 4 parts of Span 80, 75 parts of lubricating components and 0.8 parts of antioxidant;

[0057] The treatment agent is prepared through the following steps:

[0058] The first step, mixing sodium lauryl sulfate and deionized water, stirring evenly, adding sodium carboxymethylcellulose and polyvinylpyrrolidone to obtain the first mixed solution;

[0059] The second step is to add Span 80 to the lubricating component, then add antioxidant, and ultrasonically disperse for 45 minutes at a temperature of 50°C and a frequency of 45kHz; obtain the second mixed liquid;

[0060] The third step is to mix the first mixed liquid and the second mixed liquid, and stir for 4-8 hours at a...

Embodiment 3

[0073] A preparation method of a treatment agent for improving the lubricating effect of drilling fluid, comprising the following raw materials in parts by weight:

[0074] 7 parts of sodium lauryl sulfate, 20 parts of deionized water, 9 parts of sodium carboxymethylcellulose, 8 parts of polyvinylpyrrolidone, 5 parts of Span 80, 80 parts of lubricating components and 1 part of antioxidant;

[0075] The treatment agent is prepared through the following steps:

[0076] The first step, mixing sodium lauryl sulfate and deionized water, stirring evenly, adding sodium carboxymethylcellulose and polyvinylpyrrolidone to obtain the first mixed solution;

[0077] The second step is to add Span 80 to the lubricating component, then add antioxidant, and ultrasonically disperse for 60 minutes at a temperature of 60°C and a frequency of 50kHz; obtain the second mixed liquid;

[0078] The third step is to mix the first mixed liquid and the second mixed liquid, and stir for 4-8 hours at a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com